Comprehensive resource utilization method of tungsten-containing crystallization mother liquor and ammonia-containing steam

A technology of crystallization mother liquor and ammonia vapor, applied in tungsten compounds, chemical instruments and methods, preparation/separation of ammonia, etc., can solve the problems of low concentration of ammonia water recovered by ammonia-containing vapor, high equipment material requirements, and high acid-base consumption cost. , to achieve the effect of reducing material consumption, low operating cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

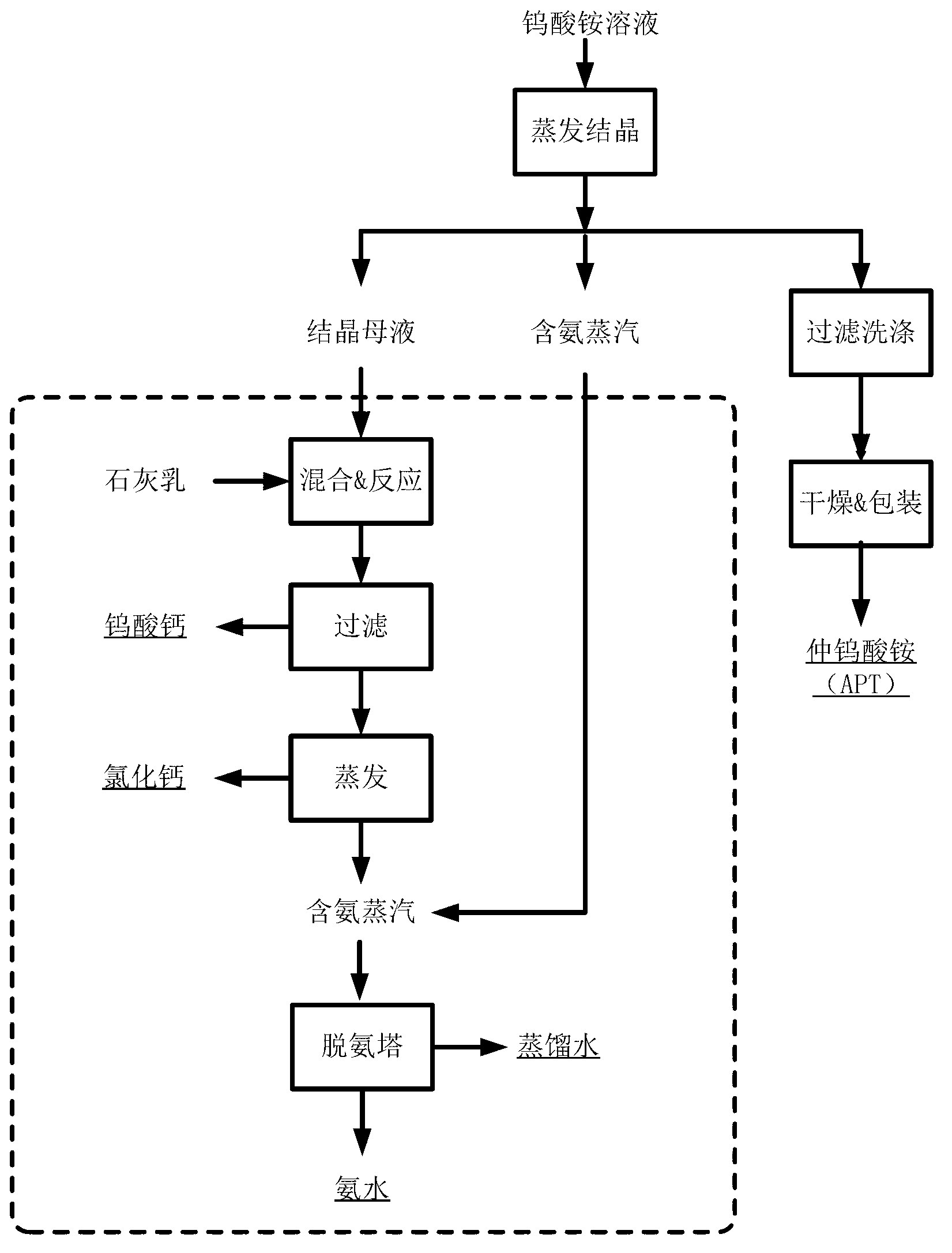

[0035] WO 3 APT crystallization mother liquor with a content of 20.5g / L; add calcium hydroxide with a theoretical multiple of 1.2 times to the crystallization mother liquor; mix in a mixing reactor, stir the mixture evenly, and pump it into a centrifugal filter for Filtration; the solid phase after filtration is calcium tungstate product for further processing and recovery of WO 3 ; The filtered liquid phase is heated by steam, and the heated solid phase is calcium chloride for further processing and recovery; the heated liquid phase is ammonia-containing steam.

[0036]Ammonium tungstate evaporation and crystallization to prepare ammonium paratungstate (APT) product process; ammonia-containing steam is mixed with the above-mentioned ammonia-containing steam through the pipeline and then enters the packed tower. The operating pressure in the tower is 0.8MPa, and the ammonia-containing steam concentrates ammonia in the packed tower; The steam at the top of the tower is the mix...

Embodiment 2

[0038] WO 3 APT crystallization mother liquor with a content of 32.5g / L; add calcium oxide with a theoretical multiple of 1.5 times to the crystallization mother liquor; after ultrasonic mixing, pump the mixed solution into a plate and frame filter press for pressure filtration; The final solid phase is calcium tungstate product for further processing and recovery of WO 3 ; The liquid phase after pressure filtration is heated by steam, and the heated solid phase is calcium chloride for further treatment and recovery; the heated liquid phase is ammonia-containing steam.

[0039] Ammonium tungstate evaporating and crystallizing ammonium paratungstate (APT) product process to prepare ammonium paratungstate (APT) steam; mixed with the above-mentioned ammonia-containing steam through the pipeline and then entering the plate tower, the operating pressure in the tower is 0.1MPa, and the ammonia-containing steam concentrates ammonia in the plate tower; The steam at the top of the tow...

Embodiment 3

[0041] WO 3 For the APT crystallization mother liquor with a content of 10.0g / L, adjust the pH value to 8 with NaOH; add calcium chloride with a theoretical multiple of 2.0 times to the crystallization mother liquor; after shaking and mixing evenly, pump the mixed solution into a vacuum filter Filtration; the solid phase after filtration is calcium tungstate product for further processing and recovery of WO 3 ; The filtered liquid phase is heated with heat transfer oil, and the heated solid phase is calcium chloride for further processing and recovery; the heated liquid phase is ammonia-containing steam.

[0042] Ammonium tungstate evaporating and crystallizing ammonium paratungstate (APT) product process; ammonia-containing steam mixed with the above-mentioned ammonia-containing steam through the pipeline and then enters the composite structure tower. The operating pressure in the tower is -0.03MPa. Concentration; the steam at the top of the tower is the mixed steam of ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com