Green environment-friendly compound fertilizer prepared from three kinds of organic-inorganic nitrogen and preparation method thereof

A kind of three kinds of nitrogen, green and environmental protection technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of reducing drying load, humic acid granulation difficulties, etc., to prevent soil compaction, improve nutrient utilization rate, and produce varieties various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

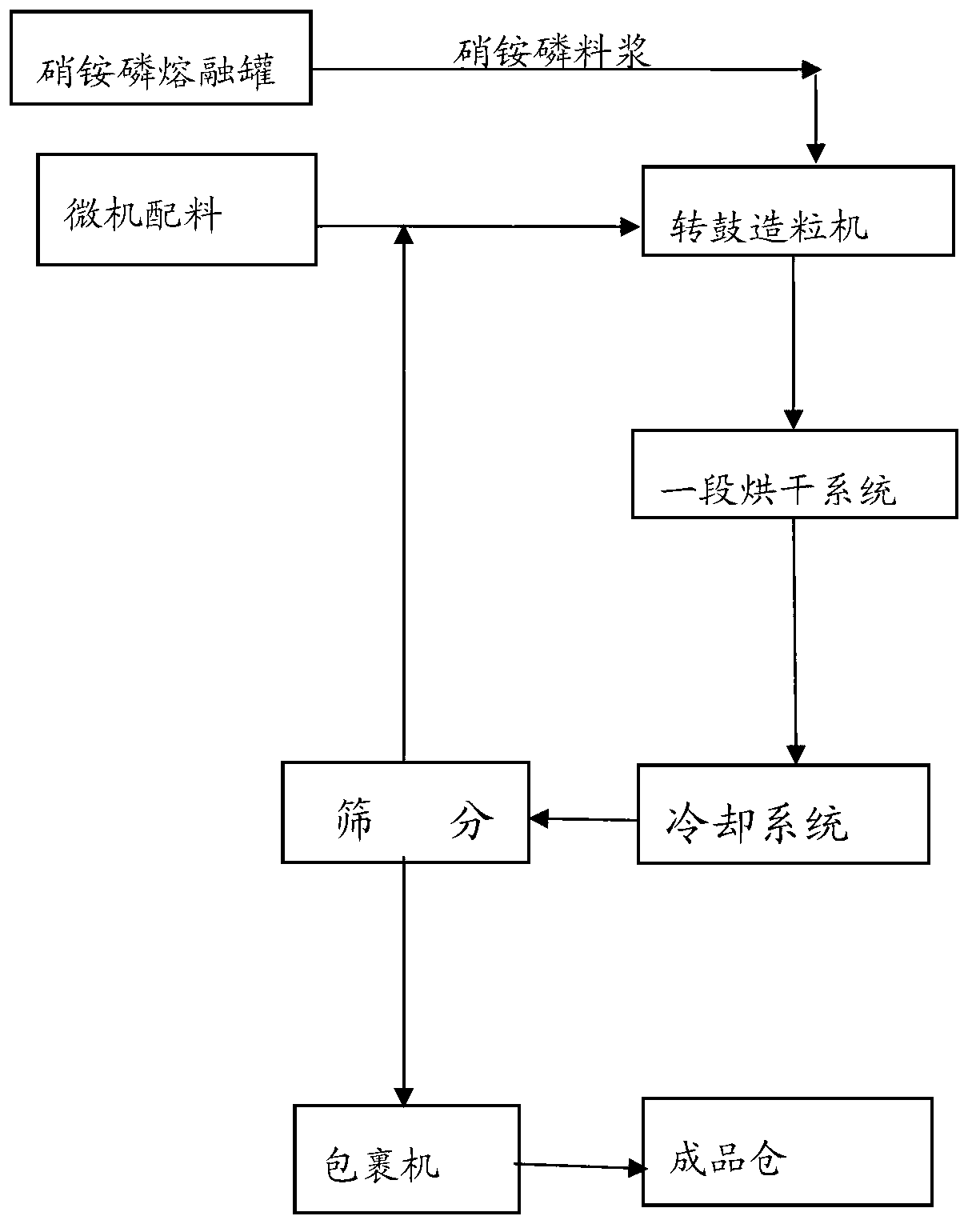

[0025] The method for preparing the above-mentioned organic-inorganic three-nitrogen green environmental protection compound fertilizer includes the following steps:

[0026] (1) In the production of compound fertilizer by granular method, 14%-22% of the total input raw materials are added into the melting tank to make a slurry with a temperature of 100-110°C for use;

[0027] (2) The metered humic acid, urea, monoammonium phosphate and potassium chloride are added to the drum granulator through the microcomputer batching system, and the ammonium nitrate phosphorus slurry prepared in step (1) is in the drum granulator Complete the granulation process. In the granulation process, the ammonium nitrate phosphorus slurry is used as the amount of liquid phase required for granulation, the heat is used to heat the material, and the viscosity of the urea nitrate generated by the reaction with urea is used to complete the material granulation process; Too much urea nitrate is produced duri...

Embodiment 1

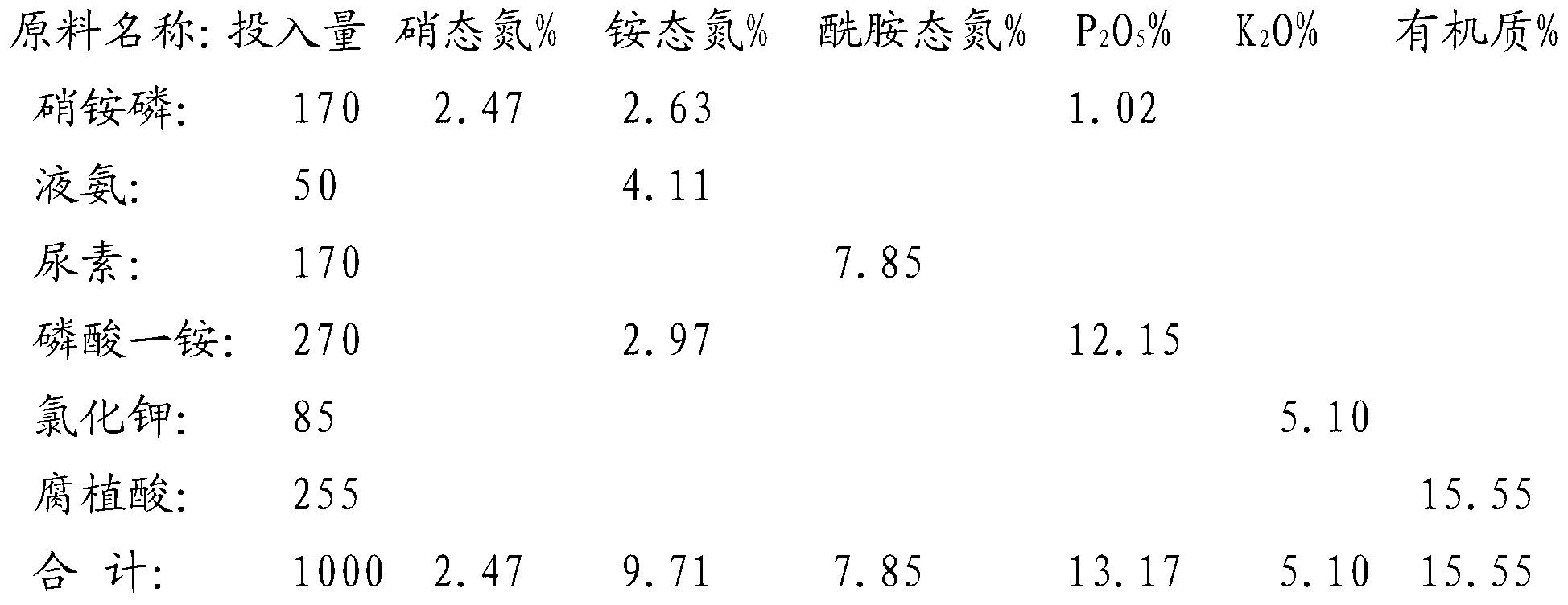

[0035] To prepare a product with 15% organic matter content and 20-13-5 nitrogen, phosphorus, and potassium content, take the raw material consumption quota of 1 ton as an example:

[0036]

[0037] Specific production process: ammonium nitrate phosphorus (containing 30% N, 14.5% nitrate nitrogen, 15.5% ammonium nitrogen, P 2 O 5 6%, mass percentage, the same below) 170 kg is metered and added to the melting device to make a slurry with a temperature of 100℃. At the same time, 170 kg of urea (containing N46.2%) and powdered monoammonium phosphate are metered by a computer. (Containing N11%, P2O545%) 270 kg, potassium chloride (containing K 2 O60%) 85 kg, humic acid (containing 61% organic matter) 255 kg, the above materials and the pressurized atomized ammonium nitrate phosphorus slurry are mixed in the drum granulator, and gas ammonia (containing N82. %) 50 kg, after being measured, pass into the drum granulator material layer, after 5min granulation, enter the dryer, the inlet a...

Embodiment 2

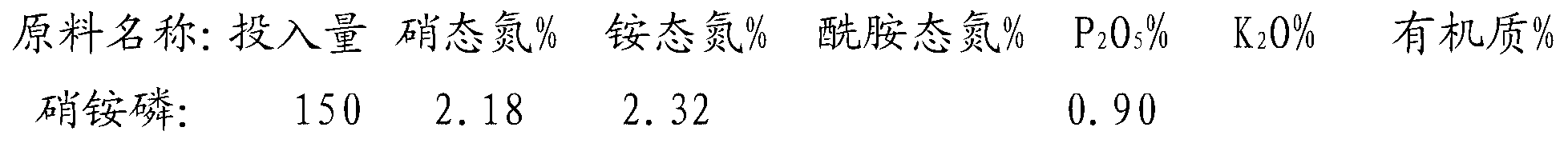

[0039] To prepare a product with an organic content of 16% and a nitrogen, phosphorus, and potassium content of 16-10-12, take the raw material consumption quota of 1 ton as an example:

[0040]

[0041]

[0042] Nitrate ammonium phosphorus (containing 30% N, which contains 14.5% nitrate nitrogen, 15.5% ammonium nitrogen, P 2 O 5 6%, mass percentage, the same below) 150 kg is metered and added to the melting device to make a slurry with a temperature of 105°C. At the same time, 150 kg of urea (containing N46.2%) and powdered monoammonium phosphate are metered by a computer (Containing N11%, P2O545%) 205 kg, potassium chloride (containing K 2 O60%) 200 kg, humic acid (containing 61% organic matter) 265 kg, the above materials and the pressurized atomized ammonium nitrate phosphorus slurry are mixed in the drum granulator, and gas ammonia (containing N82. %) 30 kg, after being measured, pass into the drum granulator material layer, after 7 minutes of granulation, enter the dryer, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com