Flexible ultraviolet light imprinting composite template and preparation method thereof

A technology of composite template and ultraviolet light, which is applied in the direction of photomechanical equipment, optics, patterned surface photoplate making process, etc., can solve the problems of non-curing components, slow preparation of PDMS, affecting the quality of imprinting, etc., and achieve the goal of short processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, the preferred embodiments are only limited to explain the present invention, the protection scope of the present invention should include the entire content of the claims, and those skilled in the art can All the contents of the claims of the present invention are realized.

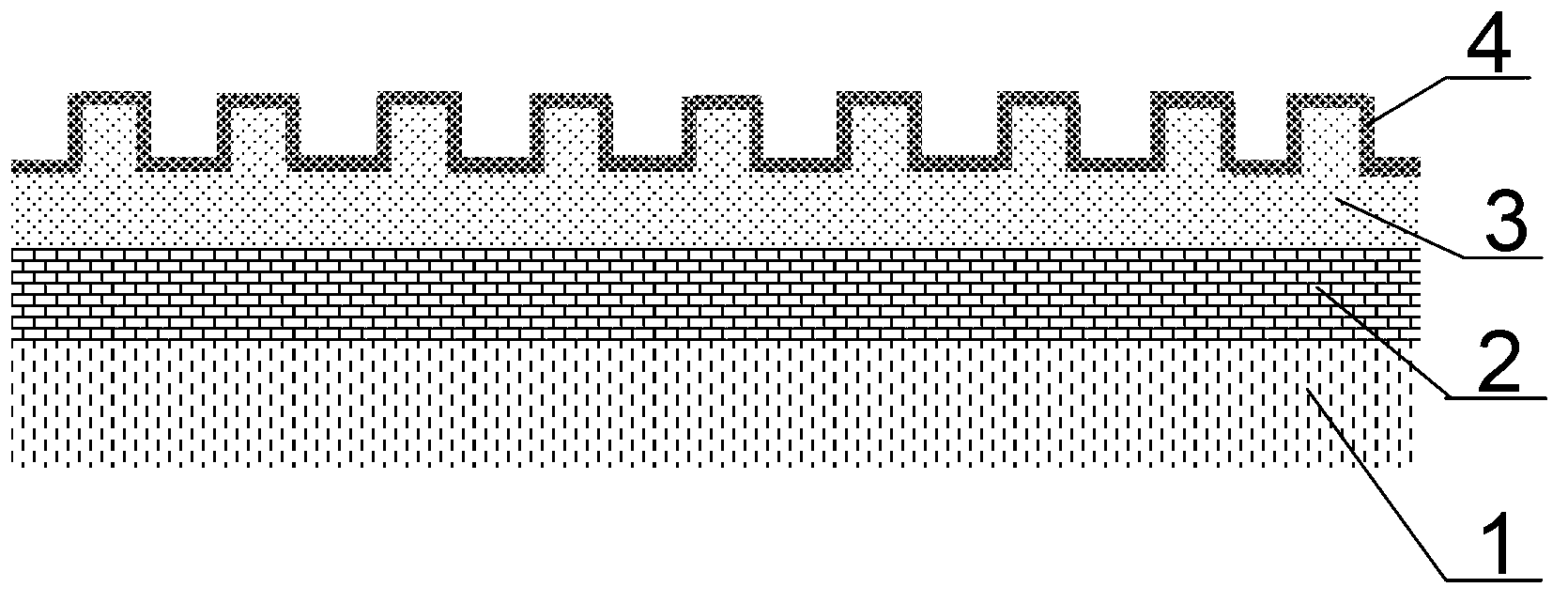

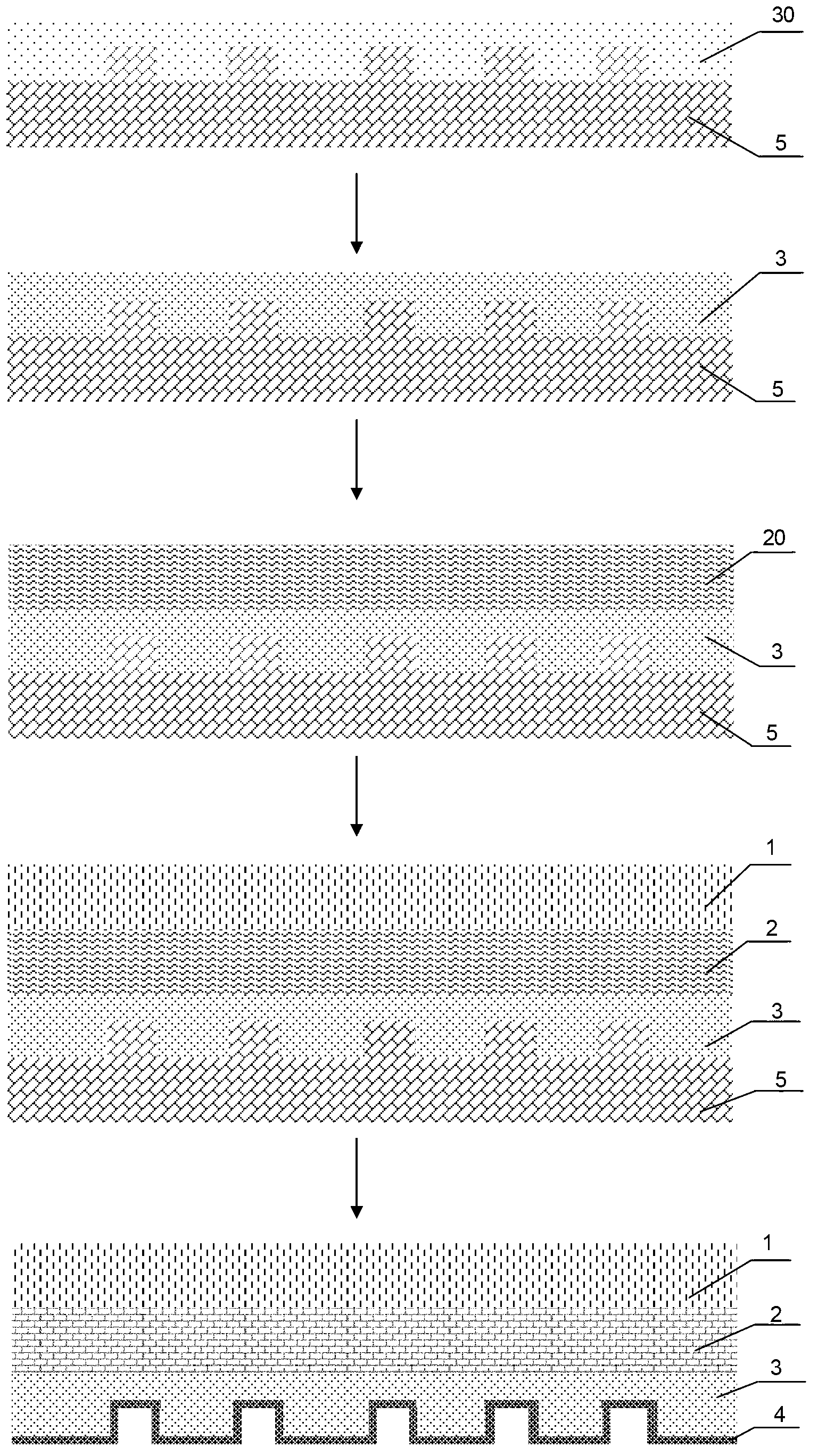

[0039] figure 1 It is a structural schematic diagram of the flexible ultraviolet imprinting composite template of the present invention. The flexible ultraviolet imprinting composite template of the present invention is a three-layer composite structure, including a flexible supporting layer 1, an intermediate layer 2 and a rigid structural layer 3.

[0040] The flexible supporting layer 1 is a flexible transparent polymer material, which can be selected from polyurethane, epoxy resin, polyester, silicone rubber, polycarbonate (PC), polymethyl methacrylate, polydimethyl ...

Embodiment 2

[0052] The flexible support layer 1 is made of GE RTV615 silicone rubber resin.

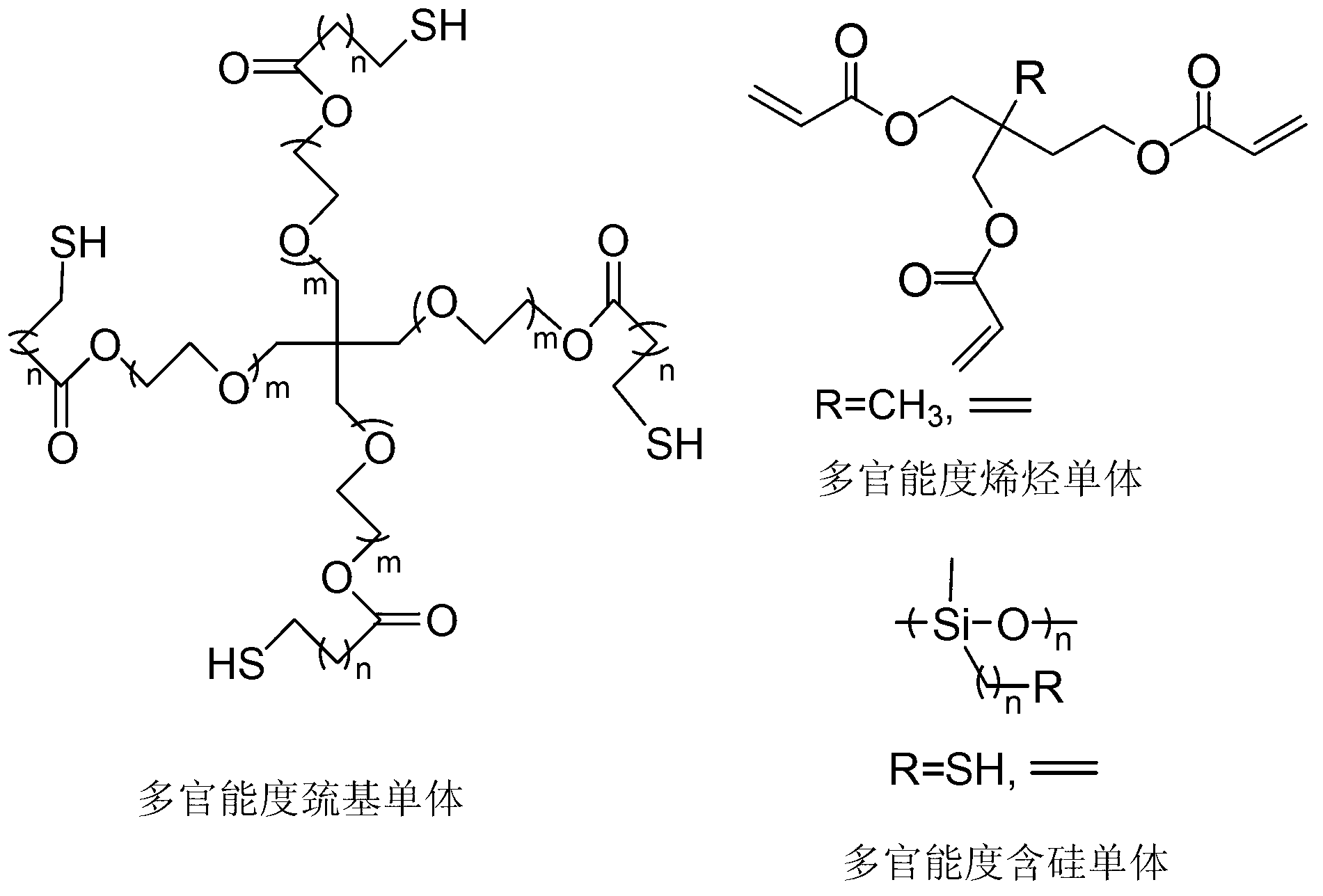

[0053] The middle layer 2 selects 3-mercaptopropionic acid-[2,4,6-trioxo-1,3,5-triazine-1,3,5(2H,4H,6H)-subgroup]tri-2, A mixture of 1-ethylene glycol ester, pentaerythritol triallyl ether, and 1,6-hexanediol diacrylate, in which 3-mercaptopropionic acid-[2,4,6-trioxo-1 ,3,5-triazine-1,3,5(2H,4H,6H)-subgroup]tri-2,1-ethylene glycol ester preferably has a mass percentage content of 60%-65%, pentaerythritol triallyl The mass percentage content of base ether is preferably 25%-30%, and the mass percentage content of 1,6-hexanediol diacrylate is preferably 5%-15%.

[0054] The rigid structure layer 3 is a mixture of (mercaptopropyl) polymethylsiloxane, pentaerythritol triallyl ether, and pentanediol diacrylate. In the mixture, (mercaptopropyl) polymethylsiloxane The mass percentage content is preferably 70%-75%, the mass percentage content of pentaerythritol triallyl ether is preferably 15%-20%, and...

Embodiment 3

[0057] The flexible support layer 1 is made of polyurethane.

[0058] The middle layer 2 selects the mixture of trimethylolpropane three (3-mercaptopropionate), triallyl isocyanurate, 1,3 dibutanol diacrylate, and in the mixture, trimethylol The mass percentage content of propane three (3-mercaptopropionate) is preferably 45%-50%, the mass percentage content of triallyl isocyanurate is preferably 35%-40%, and 1,3 dibutanol diacrylic acid The ester mass percentage content is preferably 10%-15%.

[0059] The rigid structure layer 3 is a mixture of (mercaptopropyl) polymethylsiloxane, vinyl fully substituted cage siloxane, trimethylolpropane triacrylate, and dipropylene glycol diacrylate. In the mixture, ( The mass percentage content of mercaptopropyl) polymethylsiloxane is preferably 40%-45%, the mass percentage content of vinyl fully substituted cage siloxane is preferably 10%-15%, trimethylolpropane triacrylate The mass percentage content is preferably 30%-35%, and the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com