Preparation method of mesoporous SiOx/C composite negative material of lithium-ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance of electrodes, unsuitable for large-scale preparation, complicated process, etc., and achieve good cycle stability and rate performance , facilitate large-scale preparation, the effect of uniform distribution of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

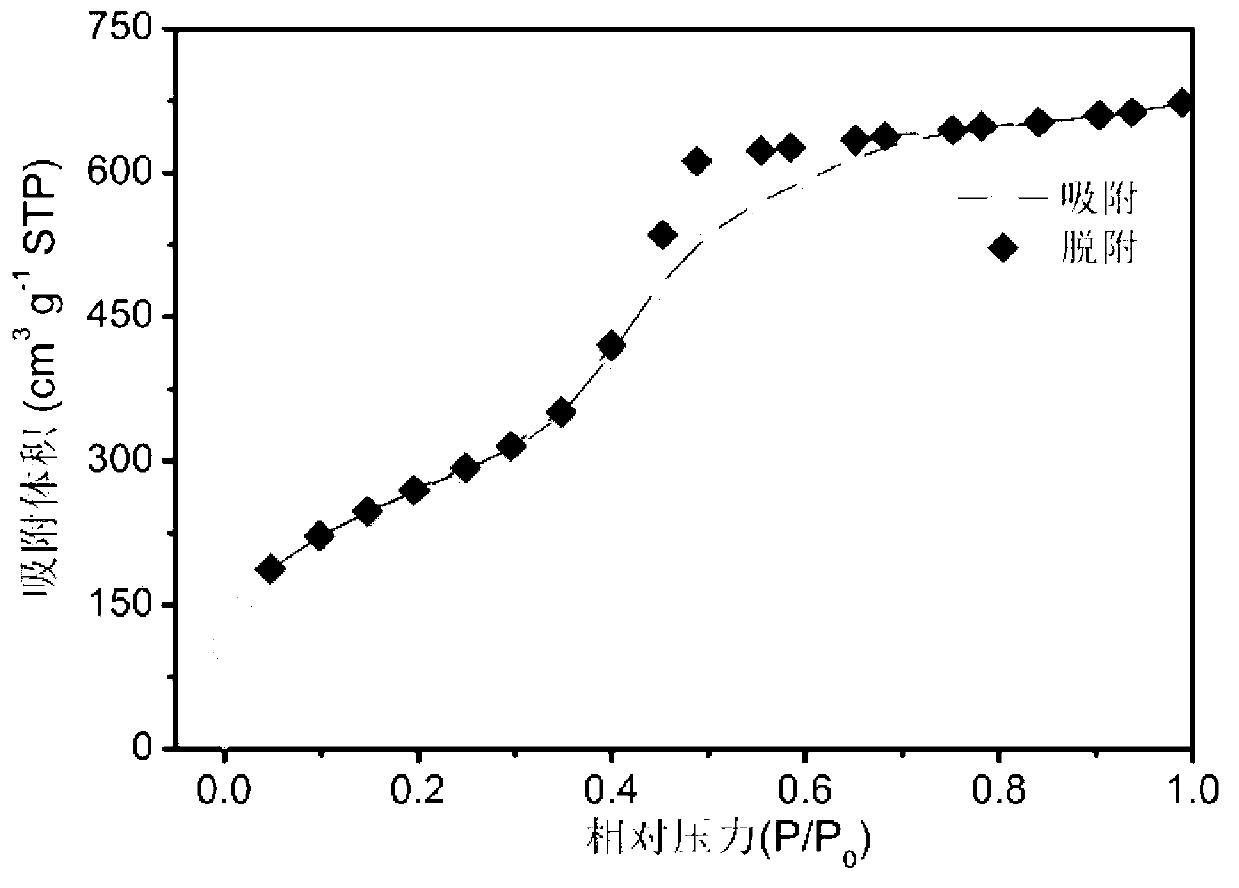

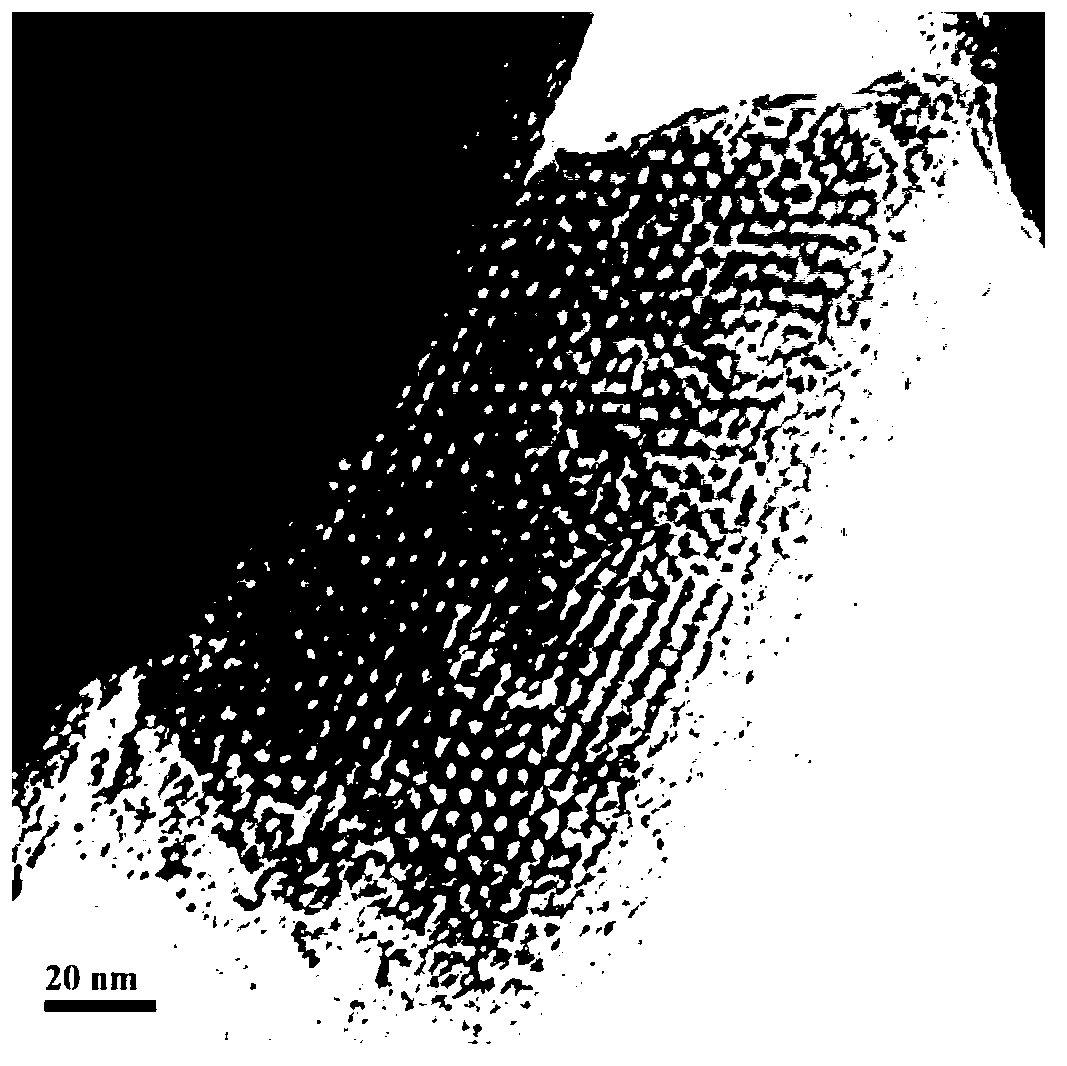

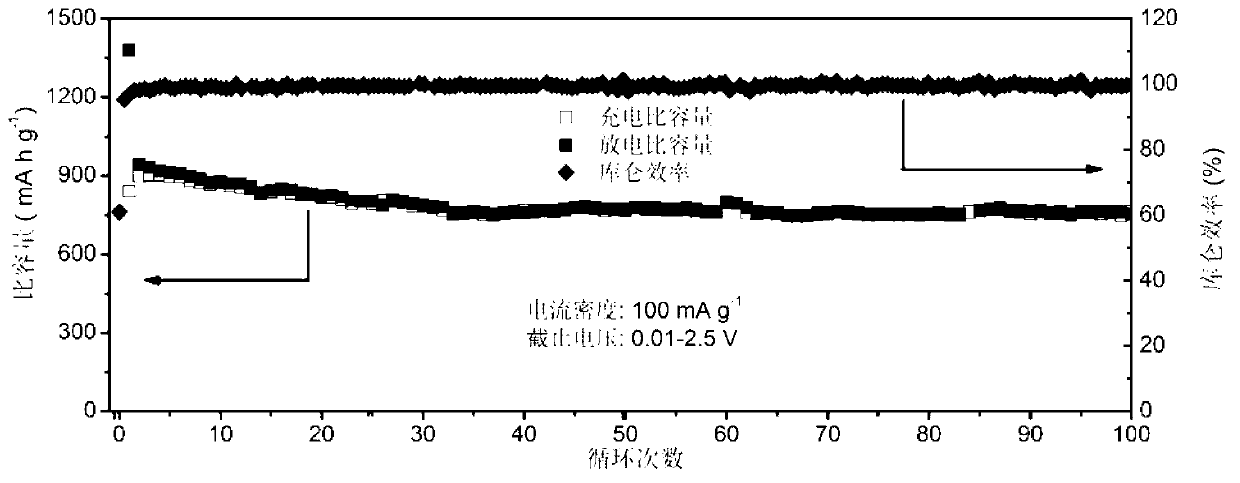

[0028] Dissolve 0.46 g of sodium hydroxide in 120 ml of deionized water and stir until completely dissolved; weigh 1.0 g of polyvinylpyrrolidone (PVP) and 1.40 g of hexadecyltrimethylammonium bromide and dissolve in the above solution, Stir until completely dissolved. Measure 5.80 ml tetraethyl orthosilicate and slowly pour it into the above solution, stir vigorously for 24 hours, and transfer the obtained white suspension to a 200 ml hydrothermal kettle with a polytetrafluoroethylene liner at 50 o C constant temperature hydrothermal treatment for 48 hours. The naturally cooled liquid was repeatedly washed with alcohol and deionized water and filtered five times, and the obtained white powder was dispersed in a 120 ml beaker and vigorously stirred for 30 min. Weigh 1.0 g of sucrose and dissolve it in the above suspension, stir until it is completely dissolved, then carry out rotary evaporation, the rotation speed is 100 rpm, and the temperature of the water area is 90 o C, o...

Embodiment 2

[0030] Dissolve 0.46 g of sodium hydroxide in 120 ml of deionized water and stir until completely dissolved; weigh 1.0 g of polyvinylpyrrolidone (PVP) and 1.30 g of dodecyltrimethylammonium bromide and dissolve in the above solution, Stir until completely dissolved. Measure 5.80 ml tetraethyl orthosilicate and slowly pour it into the above solution, stir vigorously for 24 hours, and transfer the obtained white suspension to a 200 ml hydrothermal kettle with a polytetrafluoroethylene liner at 80 o C constant temperature hydrothermal treatment for 48 hours. The naturally cooled liquid was repeatedly washed with alcohol and deionized water and filtered five times, and the obtained white powder was dispersed in a 120 ml beaker and vigorously stirred for 30 min. Weigh 1.0 g of sucrose and dissolve it in the above suspension, stir until it is completely dissolved, then carry out rotary evaporation, the rotation speed is 100 rpm, and the temperature of the water area is 90 o C, obt...

Embodiment 3

[0032] Dissolve 0.46 g of sodium hydroxide in 120 ml of deionized water and stir until completely dissolved; weigh 1.0 g of polyvinylpyrrolidone (PVP) and 1.40 g of cetyltrimethylammonium bromide and dissolve in the above solution , and stir until completely dissolved. Measure 5.0 ml of methyl orthosilicate and slowly pour it into the above solution, stir vigorously for 24 hours, transfer the obtained white suspension to a 200 ml hydrothermal kettle with a polytetrafluoroethylene liner at 80 o C constant temperature hydrothermal treatment for 48 hours. The naturally cooled liquid was repeatedly washed with alcohol and deionized water and filtered five times, and the obtained white powder was dispersed in a 120 ml beaker and vigorously stirred for 30 min. Weigh 1.0 g of sucrose and dissolve it in the above suspension, stir until it is completely dissolved, then carry out rotary evaporation, the rotation speed is 100 rpm, and the temperature of the water area is 90 o C, obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com