Metal/grapheme nanocomposite and preparation method thereof

A nanocomposite material and nanocomposite technology, applied in the direction of nanotechnology, nanotechnology, non-metallic elements, etc., can solve the problems of difficult particle size and shape, large particle size, toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

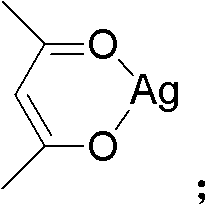

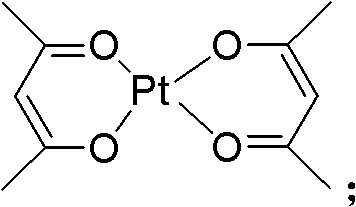

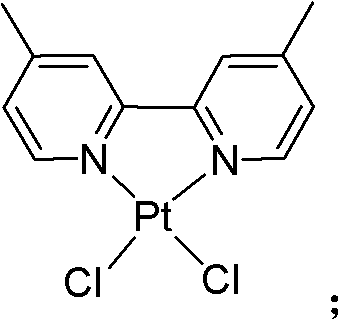

Method used

Image

Examples

Embodiment 1

[0084] 1. Synthesis of graphene oxide

[0085] 1) Expansion treatment of graphite

[0086] Heat 9ml of concentrated sulfuric acid to 80°C, add 1.6g of potassium peroxodisulfate and 1.6g of phosphorus pentoxide, stir at this temperature to completely dissolve the solid, then slowly add 2g of 320-mesh flake graphite, and finish adding within 5 minutes , the mixture was reacted at 80°C for 4.5h, cooled to room temperature after the reaction was completed, then added 350ml of deionized water, after standing for 12h, the mixture was filtered through a 0.2μm filter membrane, and the residual acid and solids were washed away with a large amount of water. Place at room temperature for 12h.

[0087] 2) Oxidation of expanded graphite

[0088] Take 80ml of concentrated sulfuric acid and place it in an ice bath at 0°C, add the expanded graphite obtained in step 1) to the sulfuric acid solution, then slowly add 10g of potassium permanganate under stirring, and ensure that the temperature...

Embodiment 2

[0098] Example 3

Embodiment 3

[0100] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com