Acetylacetone manganese-initiated RAFT (reversible addition fragmentation chain transfer) polymerization method

A technology of manganese acetylacetonate and RAFT, applied in the field of RAFT polymerization initiated by manganese acetylacetonate, can solve the problems of low conversion rate, high polymerization temperature, and no reports on initiation of polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Mn(acac) 3 Under the combined action of / MECTP, bulk synthesis of polyvinyl acetate (PVAc)

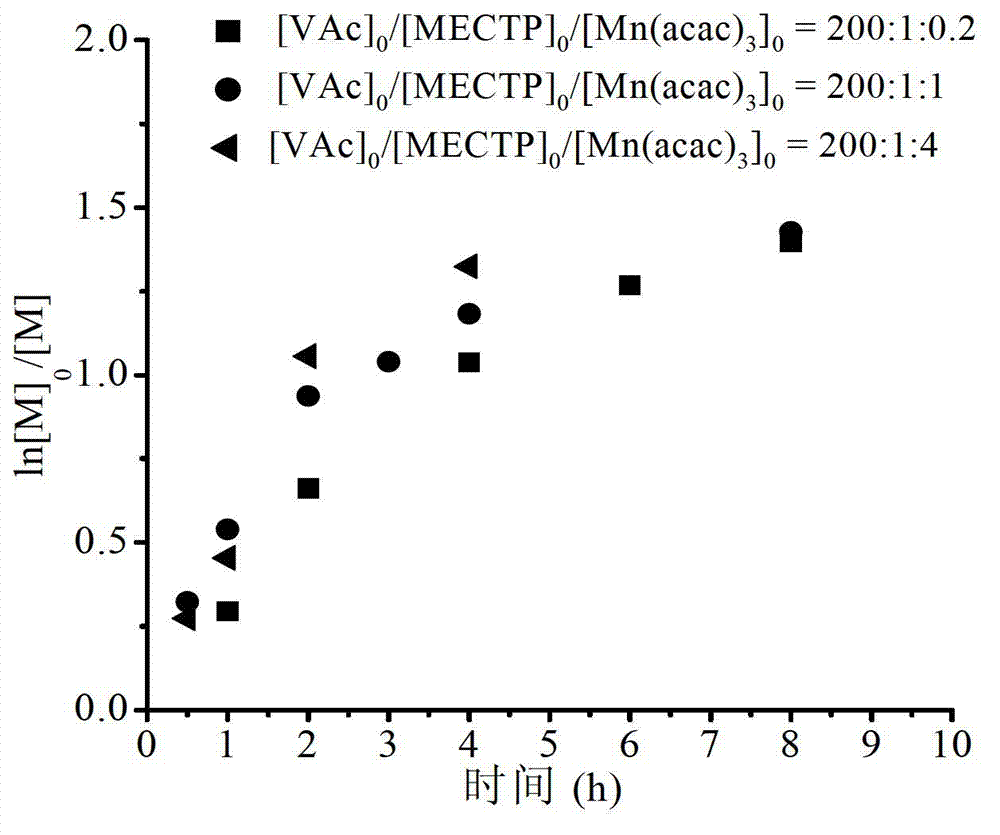

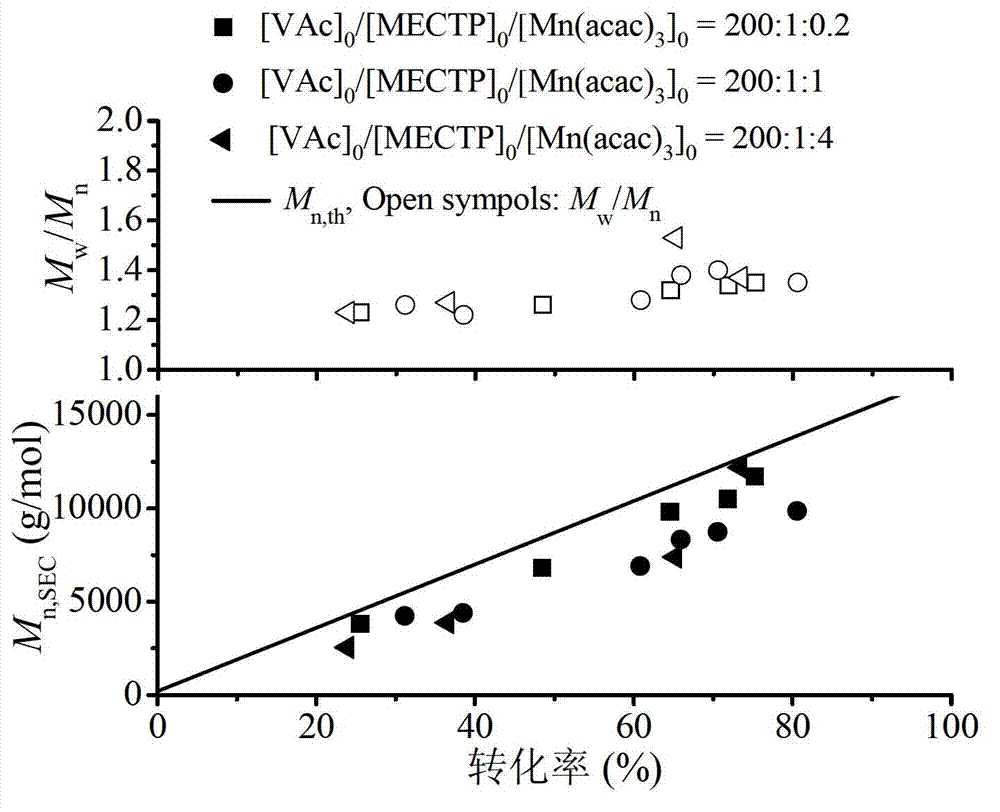

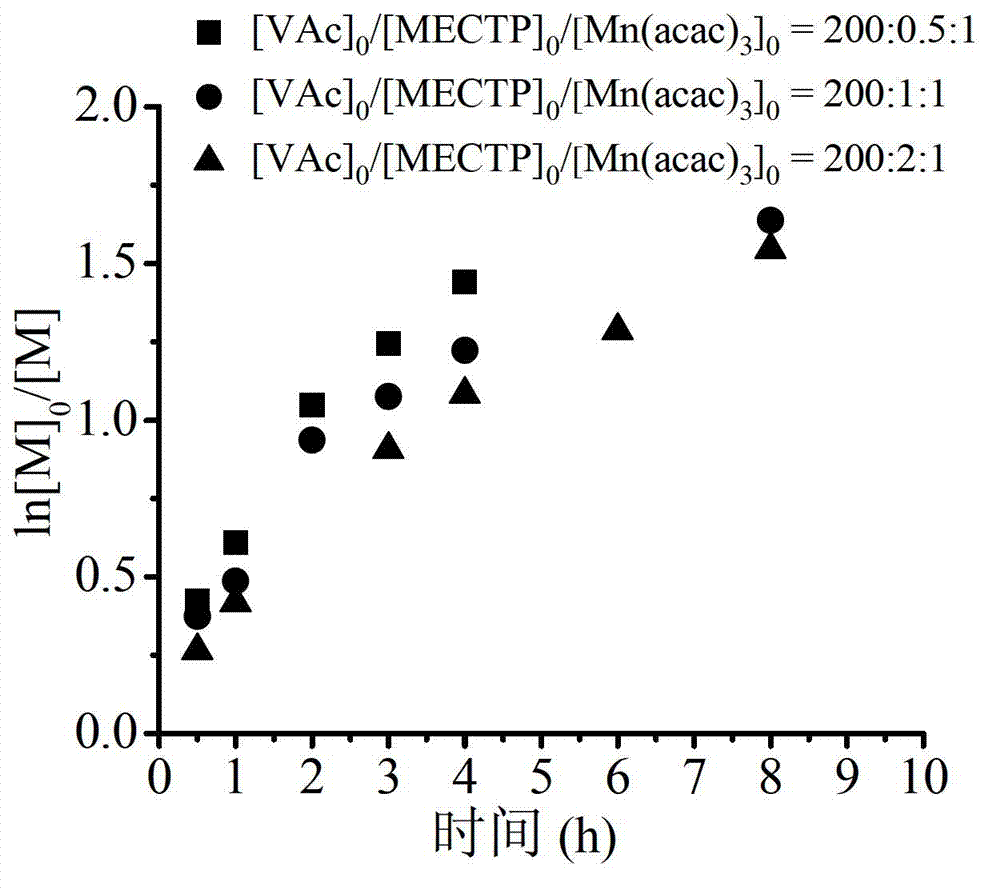

[0039] According to the ratio [VAc] 0 :[MECTP] 0 :[Mn(acac) 3 ] 0 =200:(0,0.5,1,2):(0,0.05,0.1,0.2,1,4), add Mn(acac) in turn 3 , VAc (1.0mL) and MECTP in a 5mL ampoule, add a stir bar, after 6 standard freeze-pump-thaw inflation cycles, seal the tube under an oxygen-free atmosphere. The sealed ampoule was placed in the RCT basic S25 magnetic stirrer (80°C) of IKA Company to react according to the predetermined time, and the rotation speed was 900rpm. After the reaction, take out the sealed tube, open the sealed tube, dissolve it with 2-5 mL of tetrahydrofuran, pour it into 250 mL of n-hexane, leave it overnight, filter it with suction, and dry it to obtain PVAc.

[0040] The data in the first to third rows in Table 1 is [MECTP] in Example 1 0 :[Mn(acac) 3 ] 0 =1:0.05 and 1:0.1 aggregation results; the data in the 8th to 11th rows are respectively without M...

Embodiment 2

[0046] Example 2 Under the joint action of AIBN / MECTP, bulk synthesis of PVAc

[0047] According to the ratio [VAc] 0 :[MECTP] 0 :[AIBN] 0 =200:1:(0.05,0.1,0.2,1,4), add AIBN, VAc (1.0mL) and MECTP in sequence to a 5mL ampoule, add a stirrer, and go through 6 times of standard freezing-pumping-thawing After the inflation cycle, seal the tube under an oxygen-free atmosphere. The sealed ampoule was placed in the RCT basic S25 magnetic stirrer (80°C) of IKA Company to react according to the predetermined time, and the rotation speed was 900rpm. After the reaction, take out the sealed tube, open the sealed tube, dissolve it with 2-5 mL of tetrahydrofuran, pour it into 250 mL of n-hexane, leave it overnight, filter it with suction, and dry it to obtain PVAc.

[0048] The data in the 4th to 7th rows in Table 1 is [MECTP] in Example 2 0 :[AIBN] 0 = 1:0.05 and 1:0.1 of the polymerization results of VAc.

[0049] Figure 5 Under the condition of different AIBN concentration in ...

Embodiment 3

[0055] Embodiment 3 Mn(acac) 3 Synthesis of polymethyl methacrylate (PMMA) under the combined action of / CPDN

[0056] Proportioned [MMA] 0 :[CPDN] 0 :[Mn(acac) 3 ] 0 =200:(0,0.5,1,2):(0,0.5,1,2), add Mn(acac) in turn 3 , CPDN, MMA (1.0mL) and solvent (0.5mL dimethylsulfoxide (DMSO), N,N-dimethylformamide (DMF), toluene or bulk) in a 5mL ampoule, add a stirring bar, and After 6 standard freeze-pump-thaw aeration cycles, seal the tube in an oxygen-free atmosphere. Place the sealed ampoule in a magnetic water bath at a constant temperature (25°C) for a predetermined time to react. After the reaction, take out the sealed tube, open the sealed tube, dissolve it with 2-5 mL of tetrahydrofuran, pour it into 250 mL of methanol, leave it overnight, filter it with suction, and dry it to obtain PMMA.

[0057] The data in rows 1, 3, and 4 in Table 2 are DMSO as the solvent in Example 3 without adding Mn(acac) 3 Or the polymerization results of MMA in CPDN; the data in the 5th t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com