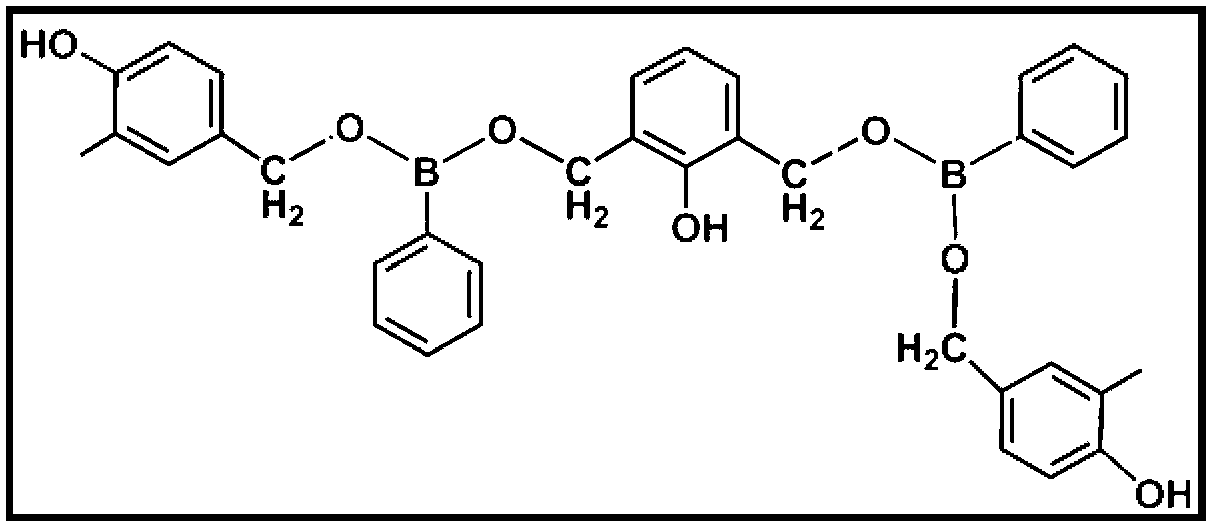

Aryl boron-containing phenolic resin and preparation method thereof

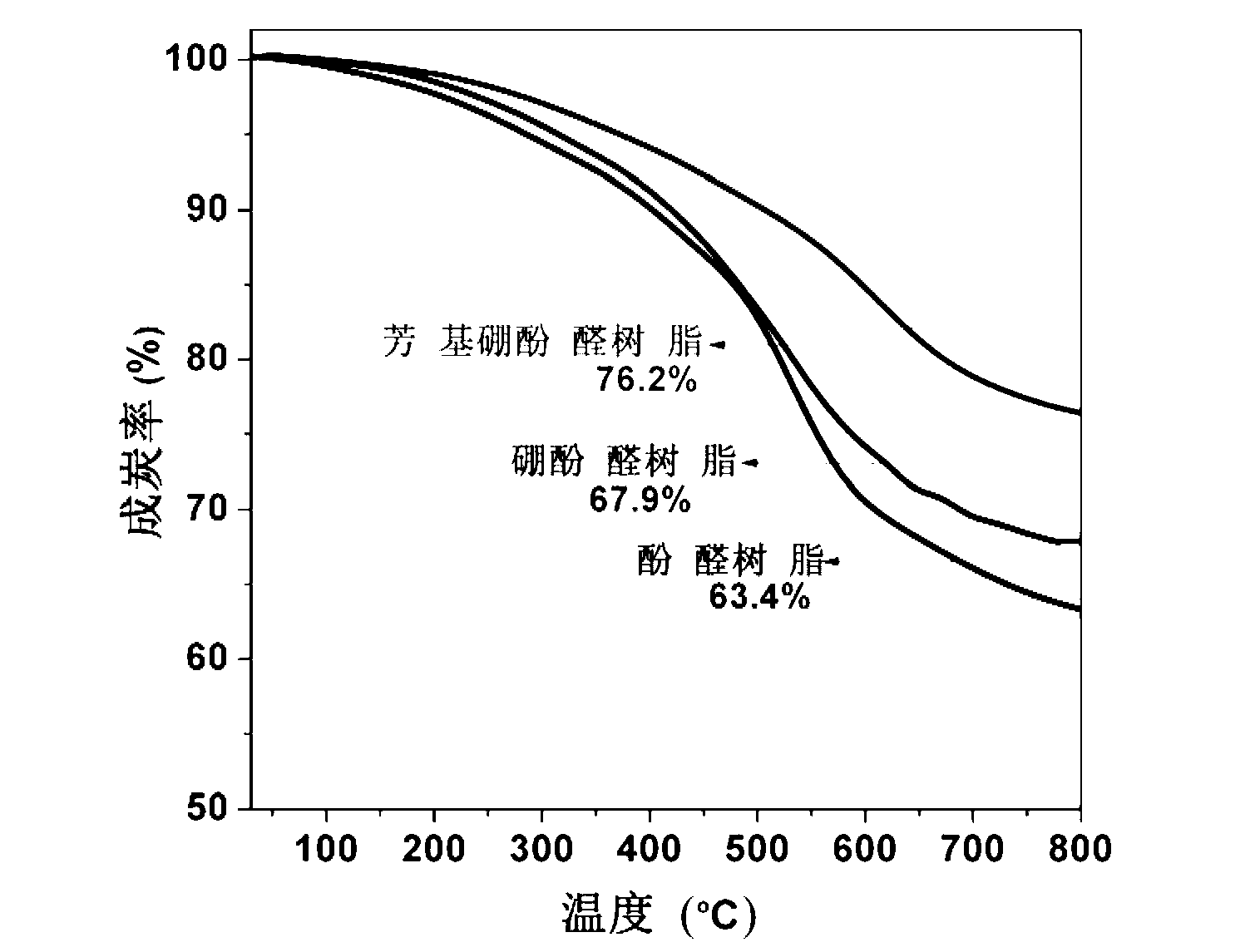

A technology of phenolic resin and aryl boron, which is applied in the field of aryl boron-containing phenolic resin and its preparation, can solve the problems of low char formation rate, unstable product quality, poor processability and mechanical properties, etc. Insufficient char formation rate and thermal decomposition temperature, superior processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

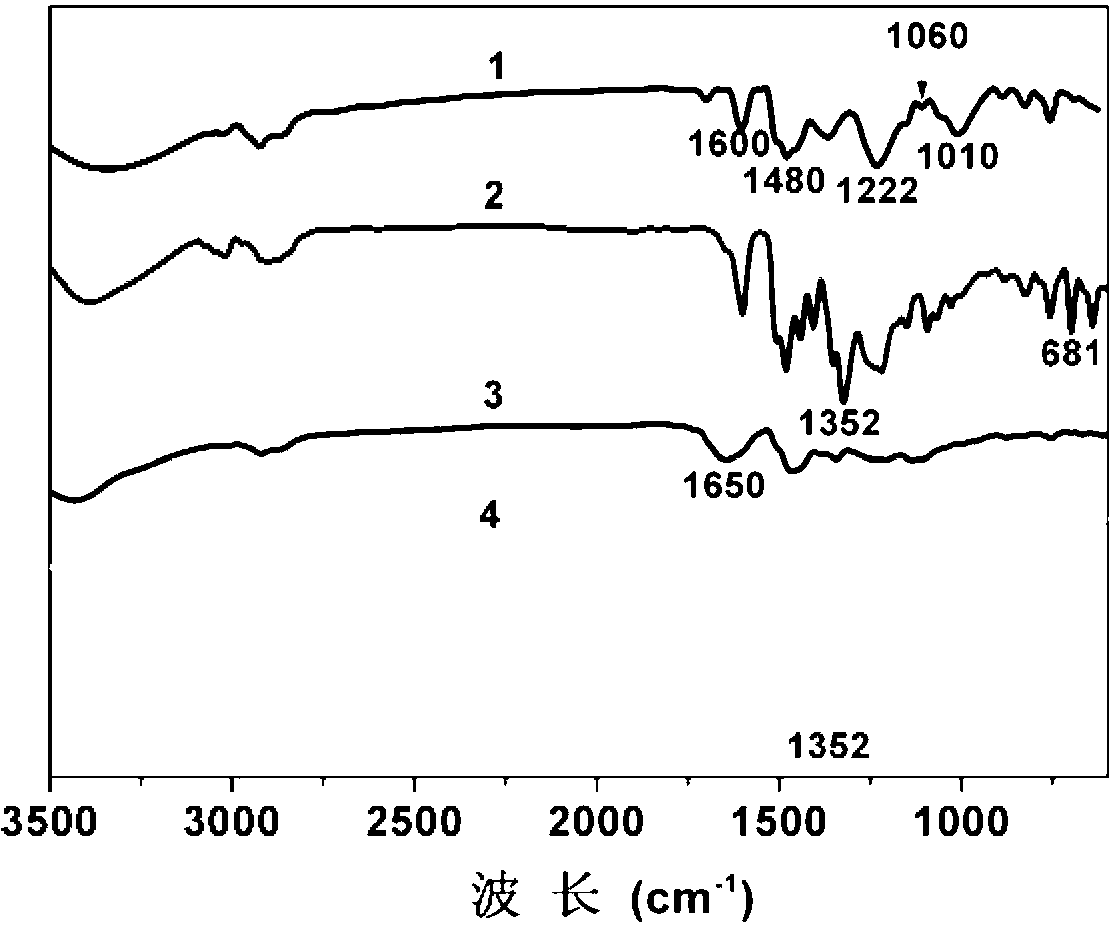

Method used

Image

Examples

Embodiment 1

[0032] According to the molar ratio of phenol / aldehyde=1:1.25. First, add 18.82g (0.2mol) of phenol and 2.96g of barium hydroxide into a four-necked flask equipped with a stirring paddle, a thermometer, a thermocouple and a condenser tube, raise the temperature to 40°C and stir to heat and melt the phenol. Then, dropwise add 20.29g37% formalin solution (0.25mol formaldehyde) in the flask, stir to make it fully mix with the material in the flask, heat up to 85°C, keep the heat for about 2.5h, and distill under reduced pressure under vacuum ( Pressure 30 ~ 100mmHg) to remove the water generated by the reaction, and the water content is less than 4%. Finally, slowly add 4.5g of phenylboronic acid into the flask, increase the reaction temperature to 115°C, and conduct the second vacuum distillation (pressure 30-100mmHg) dehydration after the heat preservation reaction for about 2 hours, and unreacted phenol with low water content The content of free phenol is less than 0.1%, and ...

Embodiment 2

[0038] According to the molar ratio of phenol / aldehyde=1:0.85. First, add 19.48g (0.46mol) of 1,4-benzenediol and 3.25g of acid catalyst (a mixture of oxalic acid and hydrochloric acid) into a four-necked flask equipped with a stirring paddle, a thermometer, a thermocouple and a condenser, and raise the temperature to 50 Stir at ℃ to heat and melt 1,4-benzenediol. Then, slowly add 8.71g of aryl boron compound (2,4,6-triphenylboroxine) into the flask, stir to make it fully mixed with the contents of the flask, raise the reaction temperature to 160°C, and keep the heat for about After 2.5 hours, after the reaction temperature drops to 55°C, vacuum distillation (pressure 30-100mmHg) removes the water generated by the reaction, and the water content is less than 4%. Finally, when the reaction temperature rose to 100°C, 20.29g of 37% formalin solution (0.25mol formaldehyde) was added dropwise to the flask, the temperature was raised to 90°C, and the second vacuum distillation (pre...

Embodiment 3

[0040] According to the molar ratio of phenol / aldehyde=1:1.25. First, add 20.02g (0.2mol) of catechol and 4.25g of sodium hydroxide into a four-neck flask equipped with a stirring paddle, thermometer, thermocouple and condenser, raise the temperature to 45°C and stir to heat and melt the catechol . Then, slowly add 3g of aryl boron compound (4-hydroxymethylphenylboronic acid) into the flask, stir to make it fully mixed with the contents of the flask, raise the reaction temperature to 180°C, and keep the reaction for about 3.5h. Add 3g of 10% concentrated sulfuric acid to the two-layer mixture to reduce the pH value of the reaction product to 6-7. After the reaction temperature drops to 45°C, distill under reduced pressure (pressure 30-100mmHg) to remove the water generated by the reaction. The water content is lower than 4%. Finally, when the reaction temperature rose to 100°C, 20.29g of 37% formalin solution (0.25mol formaldehyde) was added dropwise to the flask, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Wire ablation rate | aaaaa | aaaaa |

| Interlaminar shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com