Microencapsulated Enterococcus faecium live bacterium preparation and its preparation method

A technology of Enterococcus faecium and live bacteria preparations, which is applied in the field of microbial fermentation engineering, can solve the problems of high cost of freeze-drying technology and the easy formation of honeycombs in microcapsules, and achieve improved feed utilization, good product shape, and strong stress resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of microencapsulated Enterococcus faecium live bacteria preparation comprises the following steps:

[0019] 1. Optimization of fermentation medium:

[0020] Enterococcus faecium (Enterococcus faecium) strains were purchased from the China Common Microorganism Culture Collection and Management Center, strain number: 1.2334, and 10 factors affecting the fermentation medium were evaluated by the Plackett-Burman design method, and those with significant effects were screened out. 3 ingredients: peptone, beef extract, diammonium citrate. The steepest climbing path is used to approach the maximum yield response area of bacteroids, and the optimal level combination of the main influencing factors is determined by response surface analysis. The optimized medium composition is as follows: Enterococcus faecium fermentation medium:

[0021]

[0022]

[0023] Add the above ingredients into 1000mL distilled water, heat to dissolve, adjust the pH to 6.2...

Embodiment 2

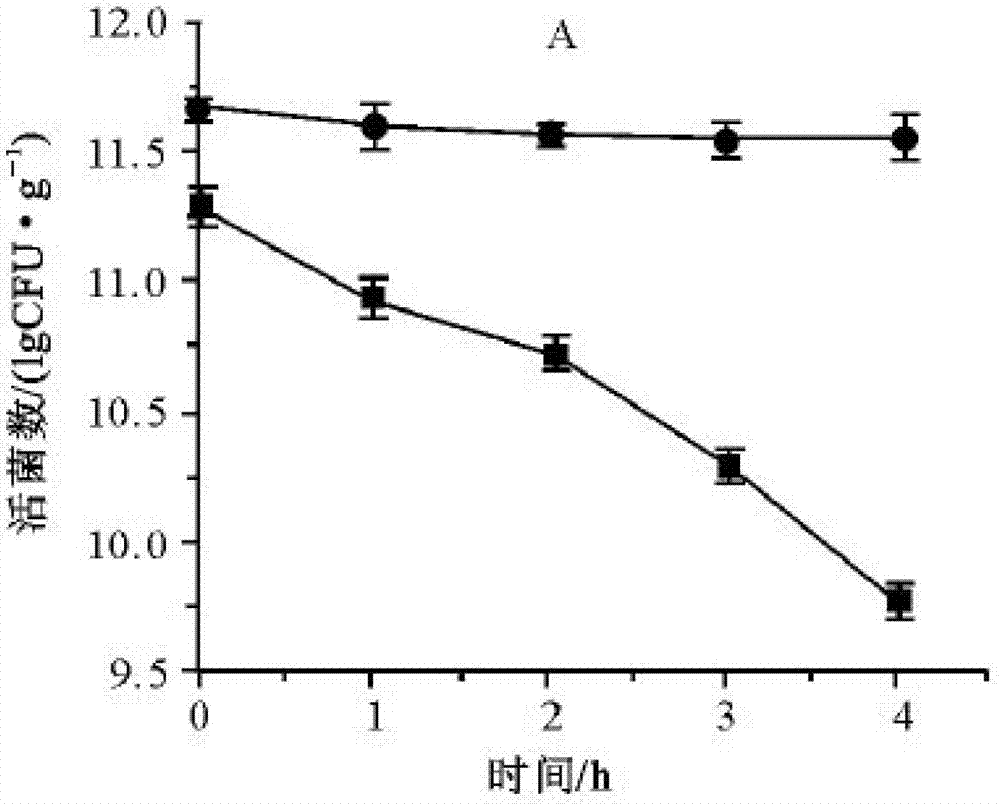

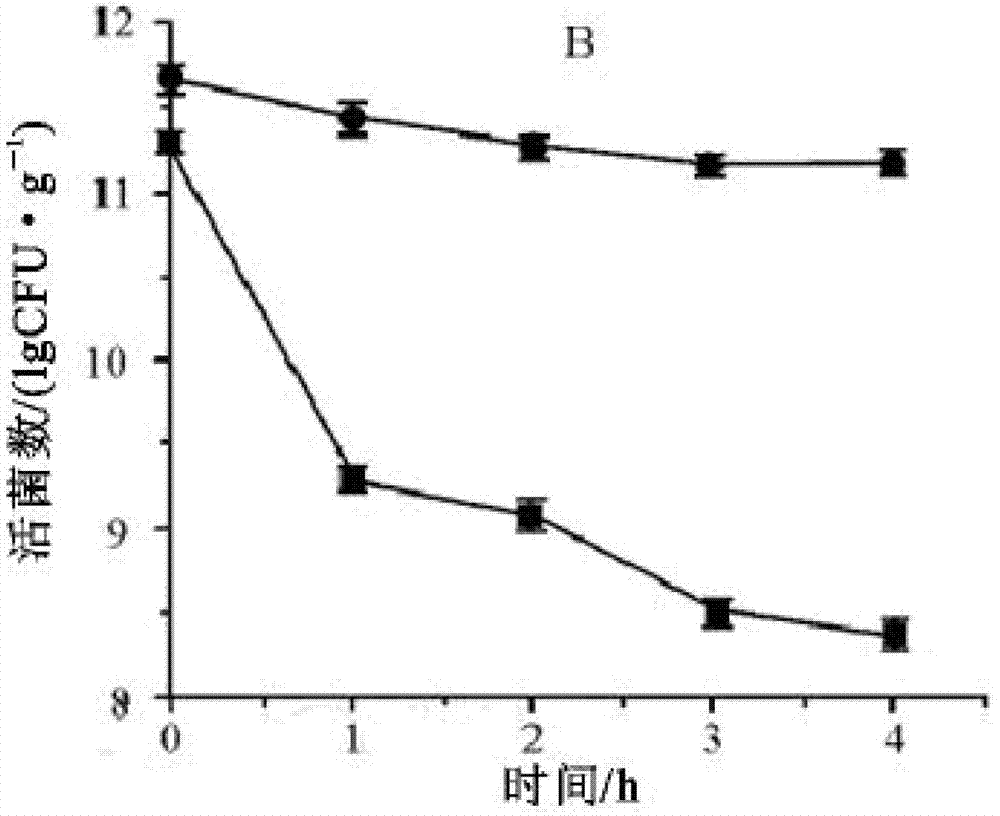

[0033] Taking the free Enterococcus faecium preparation without microencapsulation treatment as a control, the tolerance of microencapsulated Enterococcus faecium solid products to high temperature, storage and transportation, and gastric acid and bile in gastrointestinal fluids was evaluated. The test data was verified by Microsof t After preliminary sorting by Excel, Originpro7.5 was used to conduct analysis of variance and multiple comparisons, all expressed as "average ± standard deviation", with P < 0. 01 (very significant difference) and P < 0. 05 (significant difference) as Criteria for judging the significance of the difference.

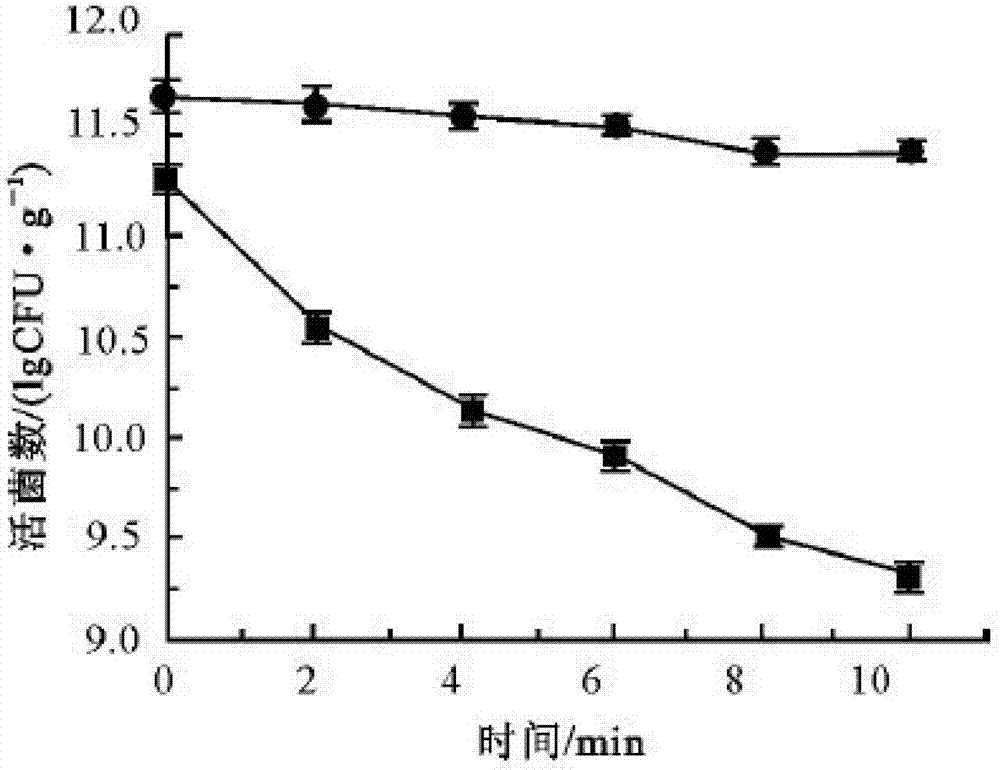

[0034] 2. 1 Resistance to high temperature

[0035] Take an appropriate amount of solid products of microencapsulated Enterococcus faecium, bathe them in water for 0, 2, 4, 6, 8 and 10 minutes at 80°C respectively, and cool them in running water. 3 replicates per treatment. Calculate the number of live bacteria per gram of product by plate ...

Embodiment 3

[0046] In order to verify the effect of microencapsulated Enterococcus faecium preparation on the growth performance and immunity of fattening pigs, 110 fattening pigs with a body weight of about 68 kg were selected in the experimental group and the control group, and 1.5% microencapsulated Enterococcus faecium preparation was added to the experimental group. The control group was not added, and other experimental conditions remained unchanged. The experimental results are shown in Table 2:

[0047] Table 1 Analysis of experimental results of microencapsulated Enterococcus faecium preparations promoting the growth of fattening pigs

[0048]

[0049] It can be seen from Table 1 that the average daily weight gain of the test group was 77.4g more than that of the control group, and the feed-to-meat ratio decreased from 3.06 in the control group to 2.72. Therefore, the microencapsulated Enterococcus faecium preparation can effectively improve feed utilization and maintain intest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com