A method for preparing high-content wc reinforced alloy powder coating

An alloy powder, high-content technology, applied in metal material coating process, coating and other directions, can solve the problems of low bonding strength, thin coating, large workpiece deformation, etc., to achieve excellent corrosion resistance and high temperature performance, substrate dilution The effect of low rate and enhanced coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

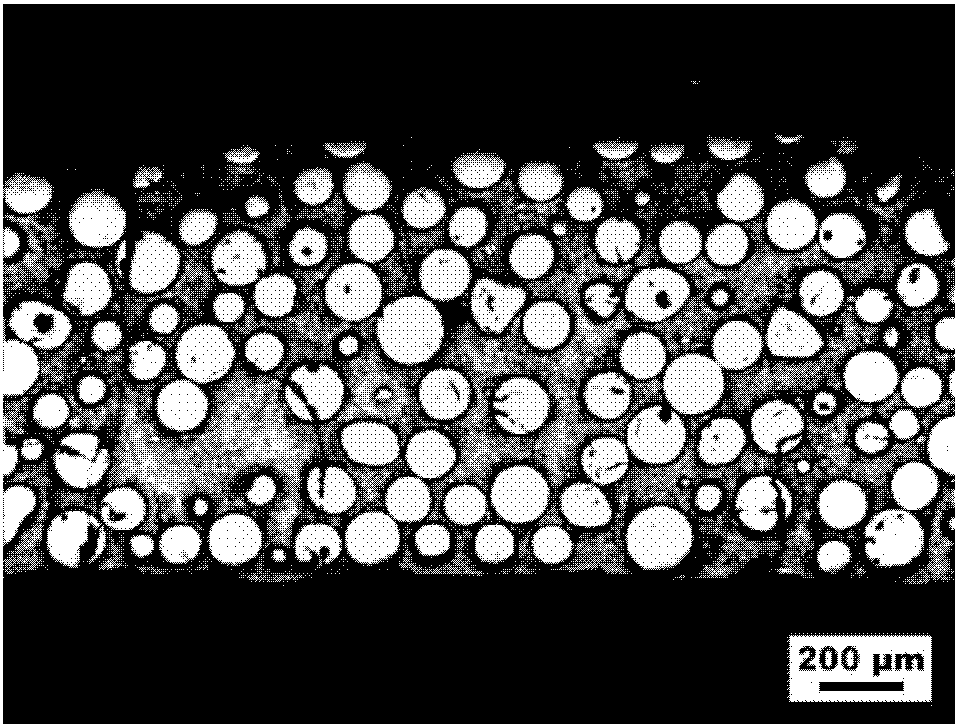

[0019] Adopt the method of the present invention to carry out the laser cladding treatment of WC reinforced alloy powder coating to the pick of mining industry, the process is as follows:

[0020] In terms of weight percentage, the hard reinforcing phase WC content is 50%, and the bonding phase powder is iron-based self-fluxing alloy powder with a brand name of XS-F50, with a content of 50%. After the two are mixed, put them into a powder mixer and fully stir them. uniform. After the surface of the pick is polished and cleaned, laser cladding is carried out. The process parameters are: laser power 3.0KW, scanning speed 700mm / min, spot diameter 3.0mm, lap rate 30%, single-layer cladding thickness 1.2mm, cladding layer.

[0021] In this example, the air-borne coaxial powder feeding method is used to feed the WC composite powder into the laser melting pool. The coaxial powder feeding system is equipped with an argon gas protection function, which can well protect the laser melti...

Embodiment 2

[0023] Using the method of the present invention to carry out the laser cladding treatment of WC reinforced alloy powder coating on the blast furnace lining plate, the process is as follows:

[0024] In terms of weight percentage, the hard reinforcing phase WC content is 70%, and the bonding phase powder is nickel-based self-fluxing alloy powder with a brand name of XS-N30, with a content of 30%. After the two are mixed, put them into a powder mixer and fully stir them. uniform. After the surface of the workpiece is polished and cleaned, laser cladding treatment is carried out. The process parameters are: laser power 6.0KW, scanning speed 2000mm / min, spot diameter 6.0mm, lap rate 50%, single-layer cladding thickness 2.0mm, cladding two layer. In this embodiment, the powder feeding method is the same as in Embodiment 1.

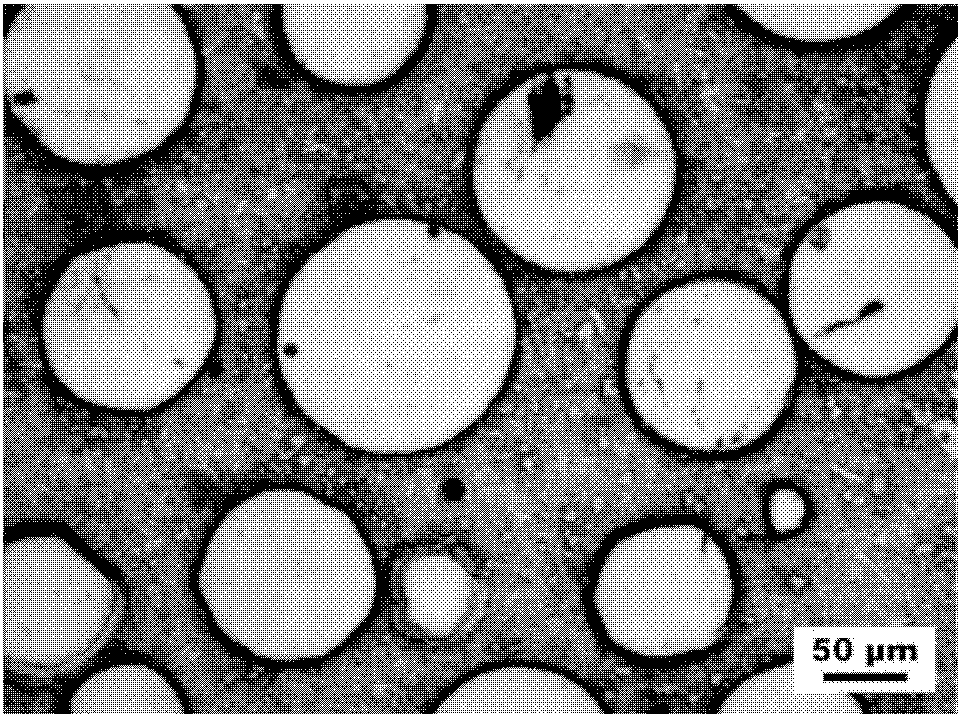

[0025] Such as image 3 As shown, the grains of the coating prepared in this example are fine and dense, and the coating structure is mainly composed of WC...

Embodiment 3

[0027] Using the method of the present invention to carry out the laser cladding treatment of WC reinforced alloy powder coating on the blast furnace lining plate, the process is as follows:

[0028] In terms of weight percentage, the WC content of the hard reinforcing phase is 60%, and the cobalt-based self-fluxing alloy powder of the brand name XS-C40 is used as the bonding phase powder, and the content is 40%. After the two are mixed, put them into a powder mixer and fully stir them uniform. After the workpiece surface is polished and cleaned, laser cladding treatment is carried out. The process parameters are: laser power 5.0KW, scanning speed 1500mm / min, spot diameter 4.5mm, lap rate 50%, single-layer cladding thickness 2.5mm, cladding two layer. In this embodiment, the powder feeding method is gravity powder feeding, and argon gas is used for protection during the cladding process.

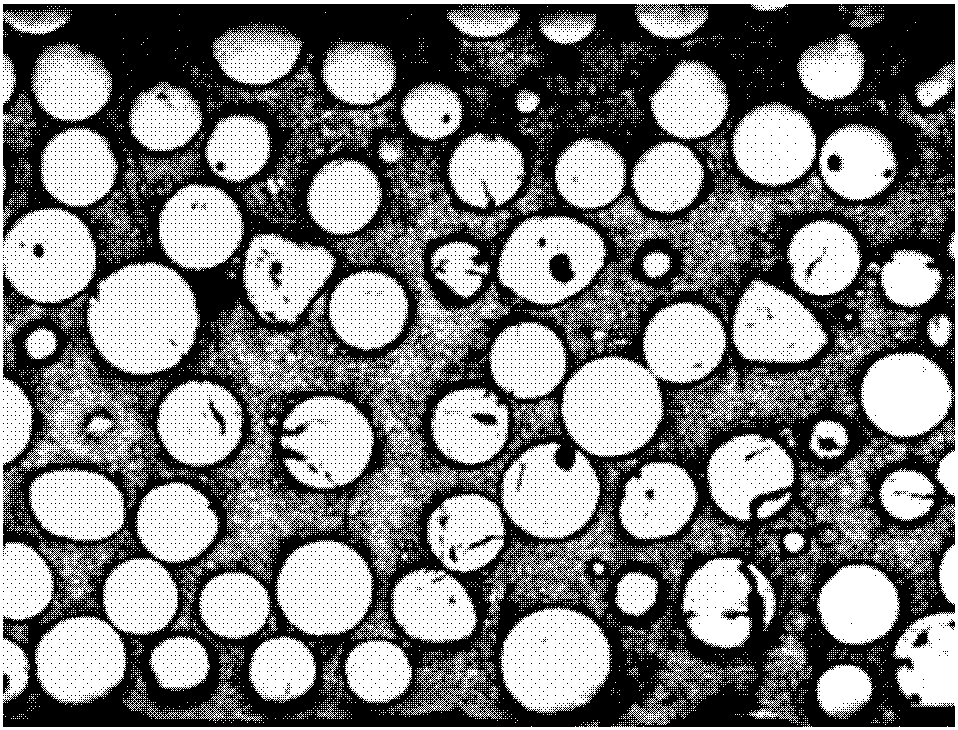

[0029] Such as Figure 4 As shown, the grain structure of the coating prepared in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com