Porous membrane for hydrogen-chloride fuel battery, as well as preparation method and application of porous membrane

A technology for hydrogen chloride fuel cells and porous membranes, which is used in fuel cell parts, final product manufacturing, sustainable manufacturing/processing, etc. It can solve the problems of low membrane porosity and adsorbed acid, and achieve high acid retention. , good strength, easy to mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

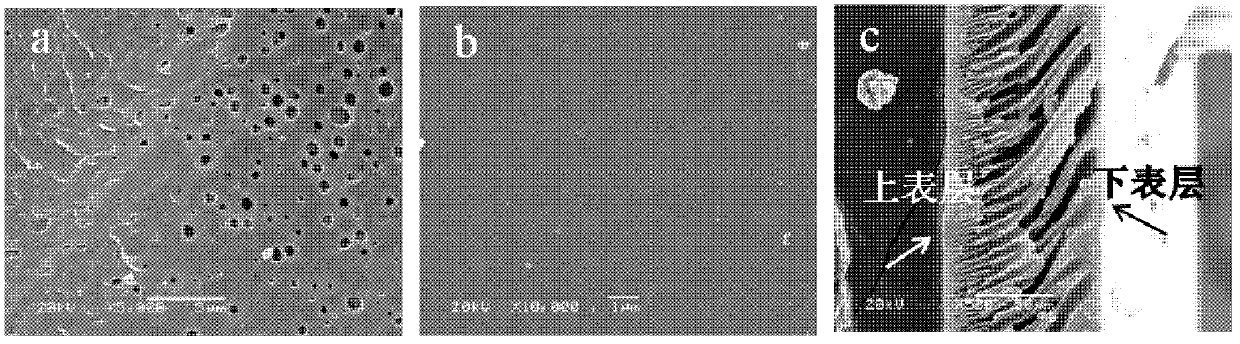

[0030] Embodiment 1: 1g of high-purity polyethersulfone (PES, molecular weight M w =58000), 0.005g SiO 2 (particle size 20-30nm), 4.6g of analytically pure DMAC and 0.3g of propylene carbonate ester were mixed, magnetically stirred at 60°C for 5h, ultrasonically mixed for 1h, left at room temperature for 3h to defoam, and scraped to form a film at room temperature. A film (thickness 85 μm) was formed by phase transformation from liquid phase to solid phase in the water. After 2 hours, the film was soaked in absolute ethanol for 4 hours, boiled in 1M hydrochloric acid at 40°C for 3 hours, and put into dilute hydrochloric acid for use. . The resulting membrane has an asymmetric structure (see the attached electron microscope photos for the lower surface, upper surface and cross-section of the membrane) figure 1 ), the contact angle of water droplets on the surface of the obtained film is 76.3 °, the porosity is 70.86%, the water absorption rate is 178.4%, the average pore diam...

Embodiment 2

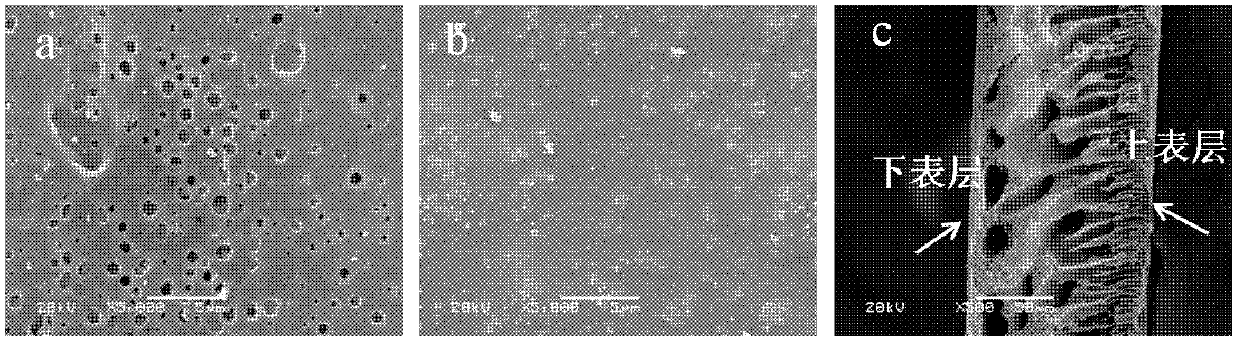

[0031] Embodiment 2: 0.9g PES (M w =58000), 0.1g SiO 2 (particle size 20-30nm), 4.2g DMF and 0.26g PVP were mixed, stirred at room temperature for 1h, ultrasonically mixed for 0.5h, vacuum defoamed at 60°C for 1h, scraped on a glass plate at room temperature, and phase-inverted into a film in 30°C water ( film thickness 70 μm), soak in n-hexane for 1 day, air-dry, and cook in 3M hydrochloric acid at 80°C for 1 hour. The resulting membrane has an asymmetric structure (see the attached electron microscope photos for the lower surface, upper surface and cross-section of the membrane) figure 2), the contact angle of water droplets on the surface of the obtained film is 65.8 °, the porosity is 71.1%, the water absorption rate is 201.6%, the average pore diameter is 12.3nm, and the minimum bubble point pressure is 0.1MPa. The film surface liquid boiled in acid is wiped clean , the ionic conductivity at room temperature was tested to be 0.106S cm -1 .

[0032] The method describ...

Embodiment 3

[0034] Embodiment 3: 0.85g PES (M w =58000), 0.15g SiO 2 (particle size 10-20nm), 4g DMAC and 0.25g glycerol were ultrasonically mixed for 3 hours, stirred at room temperature for 5 hours, degassed in a vacuum oven at 60°C, scraped the film on a glass plate at room temperature, and then put it in water at 50°C for phase inversion to form a film ( 115 μm), after 4 hours, soak the film in absolute ethanol for 12 hours, boil in 3M hydrochloric acid at 60°C for 3 hours, and put it into dilute hydrochloric acid for use. The resulting membrane has an asymmetric structure (see the attached electron microscope photos for the lower surface, upper surface and cross-section of the membrane) Figure 4 ), the contact angle of water droplets on the surface of the obtained membrane is 64.1 °, the porosity is 75.31%, the water absorption is 213.4%, the average pore diameter is 9.46nm, and the minimum bubble point pressure is 0.31MPa. The membrane surface liquid boiled in acid is wiped clean ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com