Aniline black and resin composition, aqueous dispersion, and solvent dispersion using said aniline black

A nigrosine and dispersion technology, applied in the field of nigrosine, can solve the problems of low volume impedance value, reduced charge retention ability, and high volume impedance value, and achieve the effects of excellent dispersibility, high impedance value and excellent blackness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] Add 30g (0.32mol) of aniline to 33.8g (0.33mol) of 35% hydrochloric acid and 1250ml of water, stir and mix at a liquid temperature of 60°C, and add 15.0g (0.086mol) of 4-hydroxybenzenesulfonic acid to dissolve it uniformly , add dropwise a solution of 4.6g (0.0363mol) of ferrous chloride dissolved in 70ml of water and 78.0g (0.69mol) of 30% hydrogen peroxide over 2 hours, then stir and mix at a liquid temperature of 60°C for 1 hour, and the reaction is completed . After the reaction, the reaction solution was filtered and washed with water, and the obtained filter cake was dispersed again with 1000 ml of water, neutralized to pH6.5 with 10% sodium hydroxide, and after the pH was stable, filtered and washed with water, the paste Drying at 60° C. yielded nigrosine (black pigment-1).

[0140] For the obtained nigrosine, carry out FT-IR measurement by KBr tablet method, at 1070~1030cm -1 There was a peak nearby, and the presence of a sulfo group was confirmed.

Embodiment 2~4

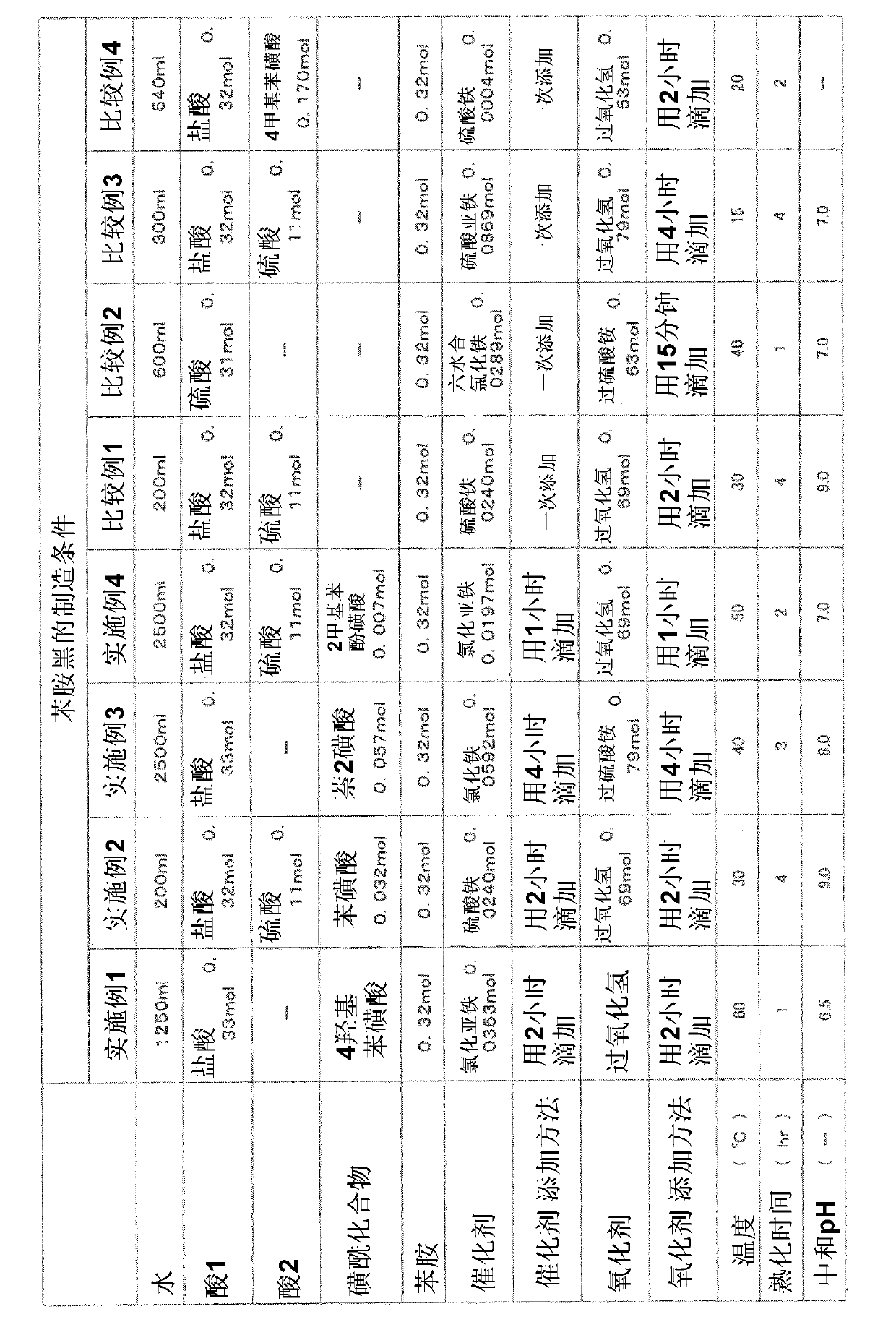

[0142] In addition to various changes to the amount of water, the type and amount of acid to be added, the type and amount of catalyst to be added, and the method of addition, the type and amount of oxidant to be added, and the method of addition, reaction temperature and aging time, and neutralization pH, the same as the above implementation Example 1 was operated in the same manner to obtain nigrosine.

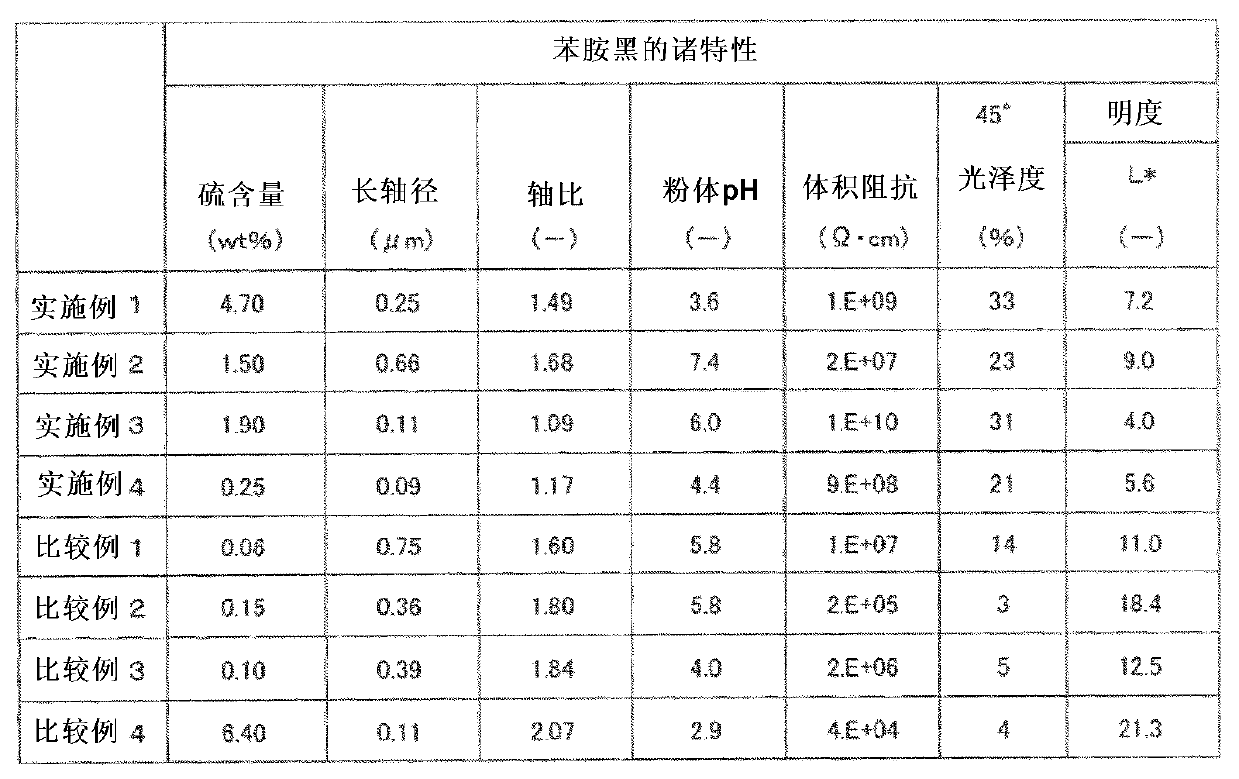

[0143] The production conditions at this time are shown in Table 1, and various characteristics of the obtained nigrosine are shown in Table 2.

[0144] The nigrosine black that embodiment 2~4 obtains, carries out FT-IR measurement by KBr tablet method, at 1070~1030cm -1 There was a peak nearby, and the presence of a sulfo group was confirmed.

Embodiment 5

[0163] 1.5 g of nigrosine obtained in Example 1 and 48.5 g of polyvinyl chloride resin powder 103EP8D (Zeon Corporation) were weighed, put into a 100 cc polyethylene beaker, and mixed well with a spatula to obtain a mixed powder.

[0164] Add 0.5g of calcium stearate to the obtained mixed powder and mix, set the gap of the hot roller heated to 160°C to 0.2mm, knead the above mixed powder in the roller little by little, and continue kneading The resin composition was peeled off from the roll until the resin composition was integrated, and used as a raw material for a colored resin sheet.

[0165] Next, the above-mentioned resin composition was sandwiched between surface-ground stainless steel plates, placed in a hot press heated to 180°C, and heated at 1 ton / cm 2 The pressure was press-molded to obtain a colored resin sheet with a thickness of 1 mm.

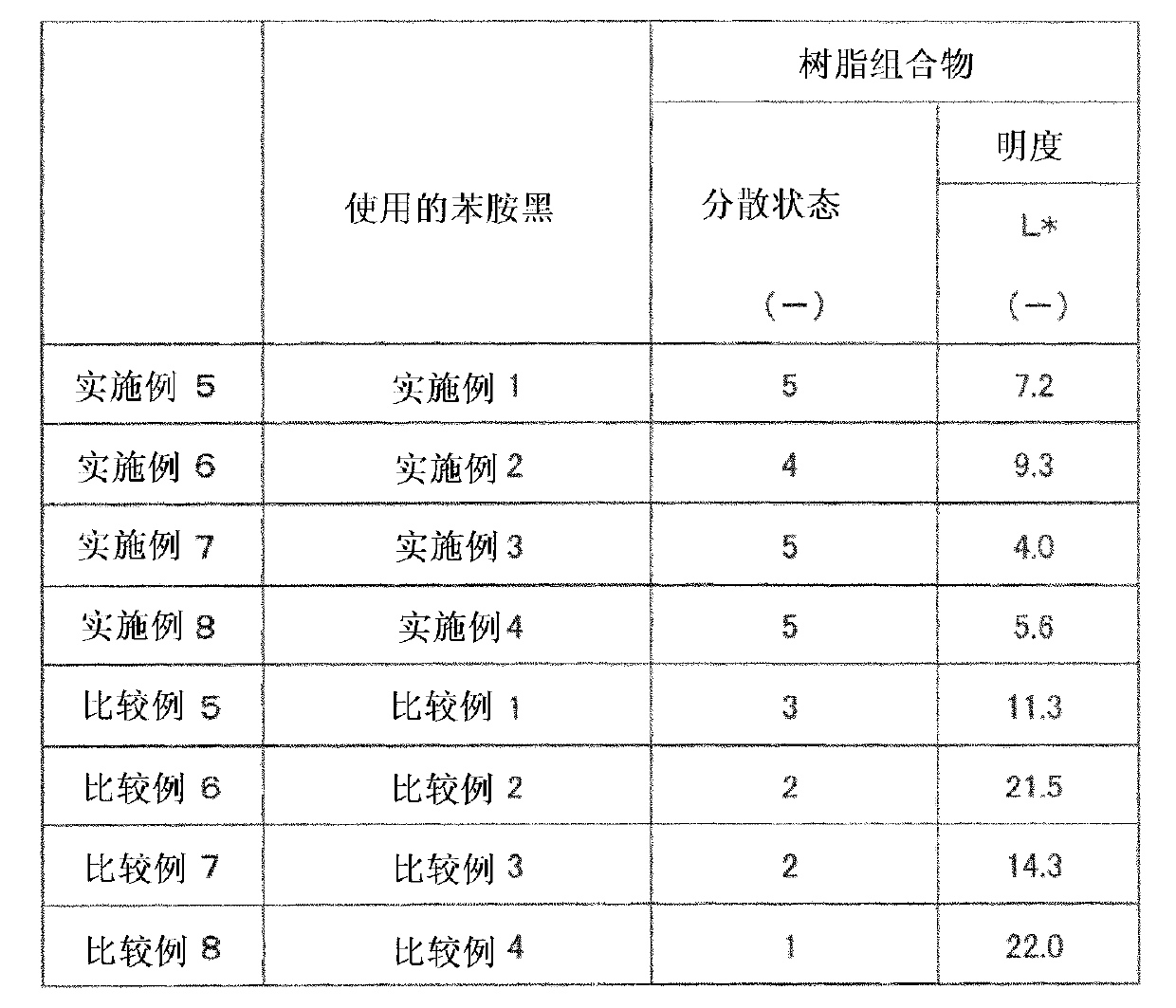

[0166] The obtained colored resin sheet had an L* value of 7.2 and a dispersion state of 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com