Method for preparing active conducting polymer hydrogel with oxidoreduction function

A technology of conductive polymers and hydrogels, applied in circuits, capacitors, electrical components, etc., can solve the problems of high specific capacity due to conductivity, and achieve the effects of maintaining cycle stability, increasing specific capacitance, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

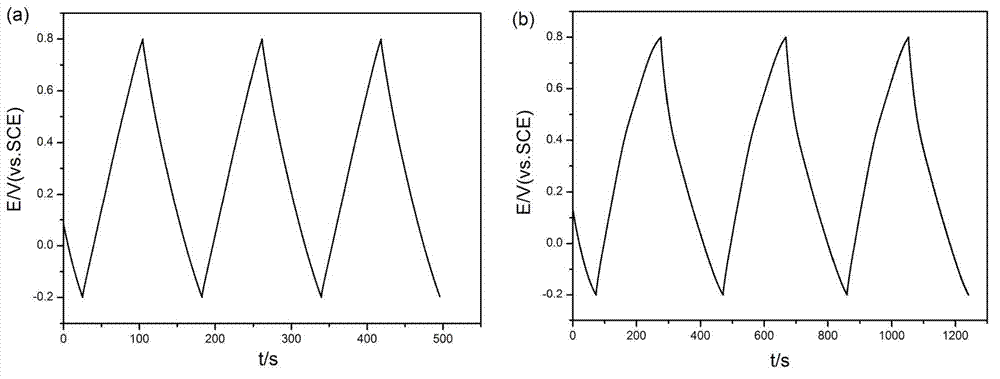

[0030] Example 1 A method for preparing PEDOT hydrogel with redox activity, the steps are as follows:

[0031] (1) 0.013g (1.3g / L, that is 4mmol / L) K 3 Fe(CN) 6 (Purchased from Sinopharm Chemical Reagent Co., Ltd.) was added to 10 mL of water, stirred and dispersed by ultrasonic to dissolve.

[0032] (2) Add 0.412g (41.2g / L, ie 0.2mol / L) of sodium polystyrene sulfonate (purchased from Aldrich, Germany) into 10mL of water, stir and use ultrasonic dispersion to form a dispersion and then follow step (1) The resulting solution is mixed, stirred and ultrasonically dispersed to form a dispersion.

[0033] (3) Add 0.853g (6mmol) of 3,4-ethylenedioxythiophene monomer (purchased from Suzhou Bohong Chemical Technology Co., Ltd.) into the dispersion formed in step (2) above, stir and use ultrasonic dispersion for 30 minutes, Evenly dispersed

[0034] (4) Add 12.12gFe(NO 3 ) 3 ·9H 2 O (ferric nitrate nonahydrate, 30 mmol, purchased from Sinopharm Chemical Reagent Co., Ltd.) was dissolved in 5 m...

Embodiment 2

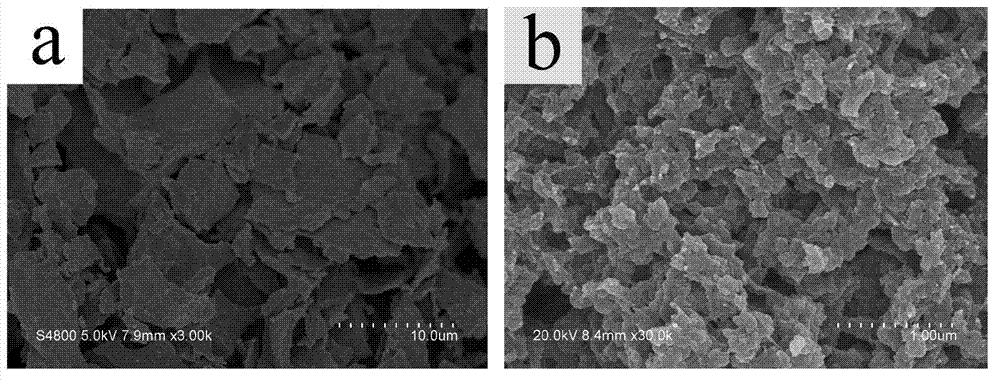

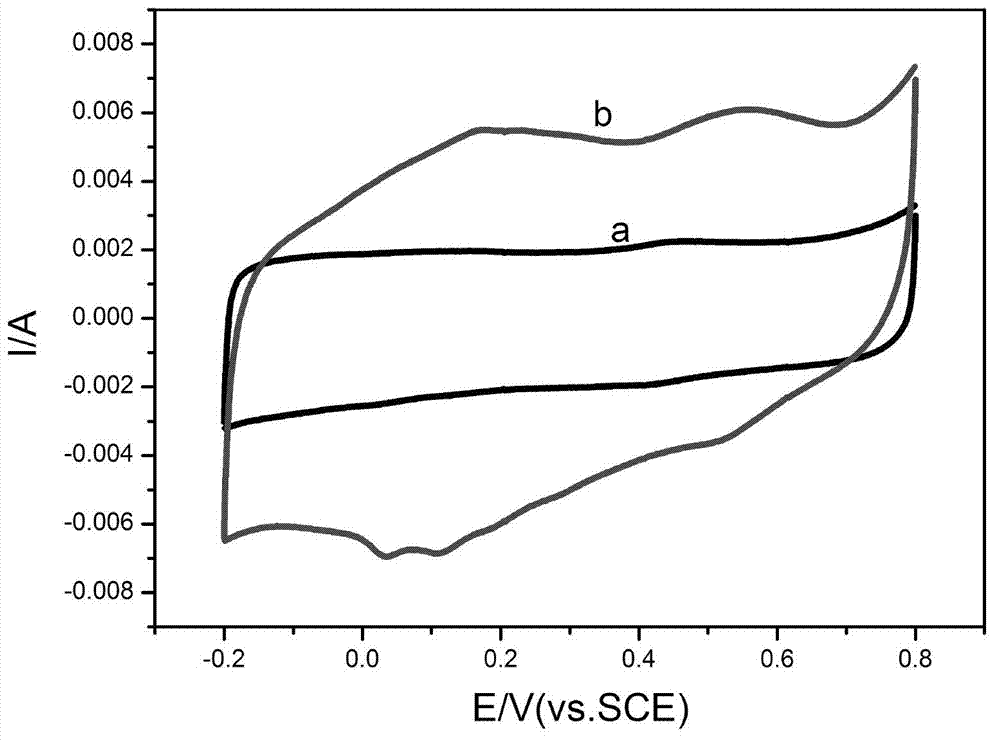

[0035] Example 2. A method for preparing PEDOT hydrogel with redox activity. The difference from Example 1 is that in step (1), K 3 Fe(CN) 6 The mass becomes 0.033g (3.3g / L, ie 10mmol / L), 12.12gFe(NO 3 ) 3 ·9H 2 O becomes 3.24gFeCl 3 .6H 2 O (12mmol, ferric chloride hexahydrate), stand for 24h to 18h. The prepared PEDOT hydrogel has a sheet size of 100-400nm and a specific capacitance of 168F / g.

Embodiment 3

[0036] Example 3. A method for preparing PEDOT hydrogel with redox activity. The difference from Example 1 is that the 3,4-ethylenedioxythiophene monomer is changed to 0.284g (2mmol), and 12.12gFe in step (4) (NO 3 ) 3 ·9H 2 O becomes 4.39gCe(NH 4 ) 2 (NO 3 ) 6 (8mmol, cerium ammonium nitrate), the purification equilibration time from 2 days to 4 days. The size of the prepared PEDOT hydrogel is 500-800nm, and the specific capacitance is 67F / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com