One-dimensional SYCO cathode material and preparation method and method to prepare composite cathode by using the cathode material

A cathode material and composite cathode technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of large cathode interface polarization resistance, and achieve the effect of increasing interface length, good thermal shock resistance, and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

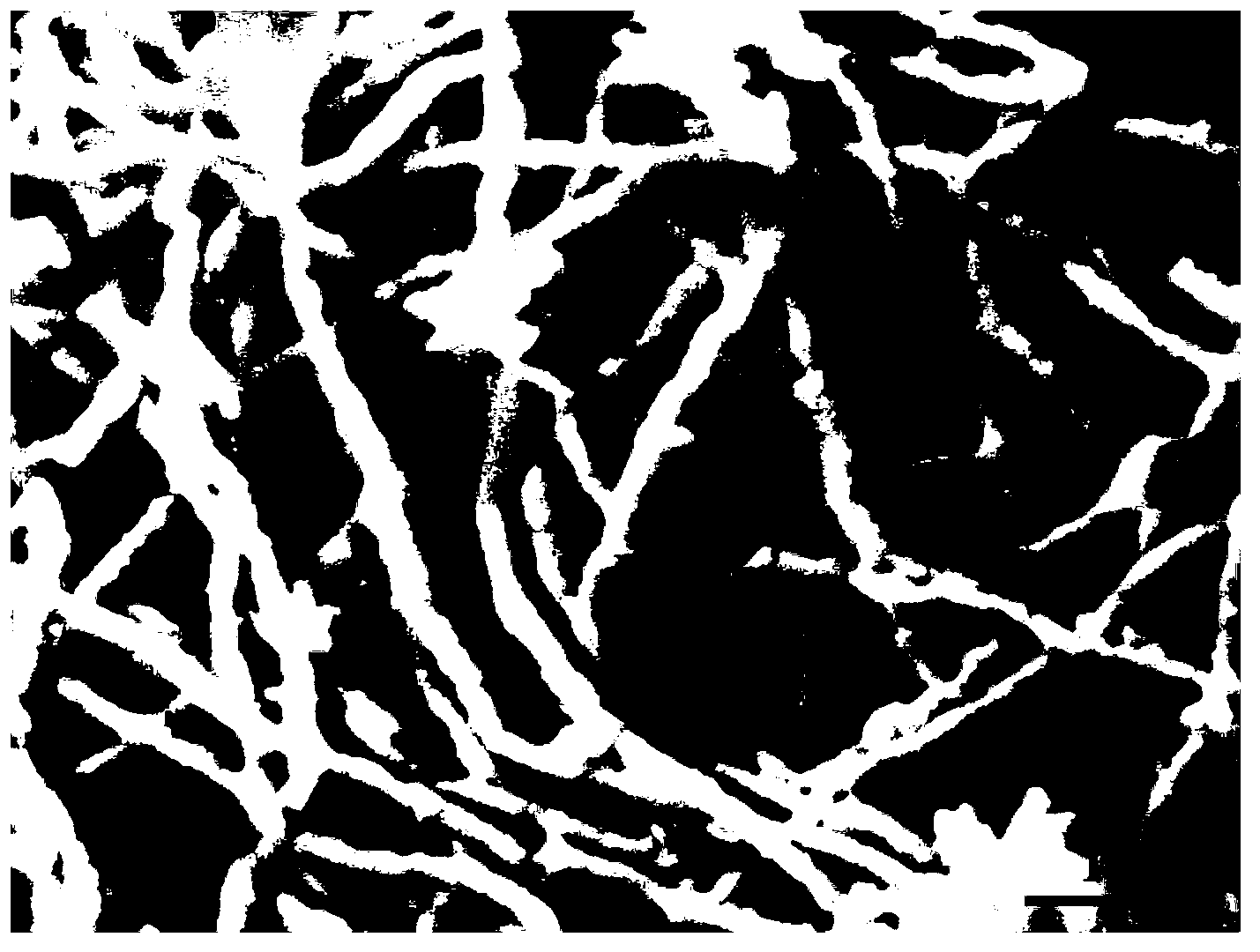

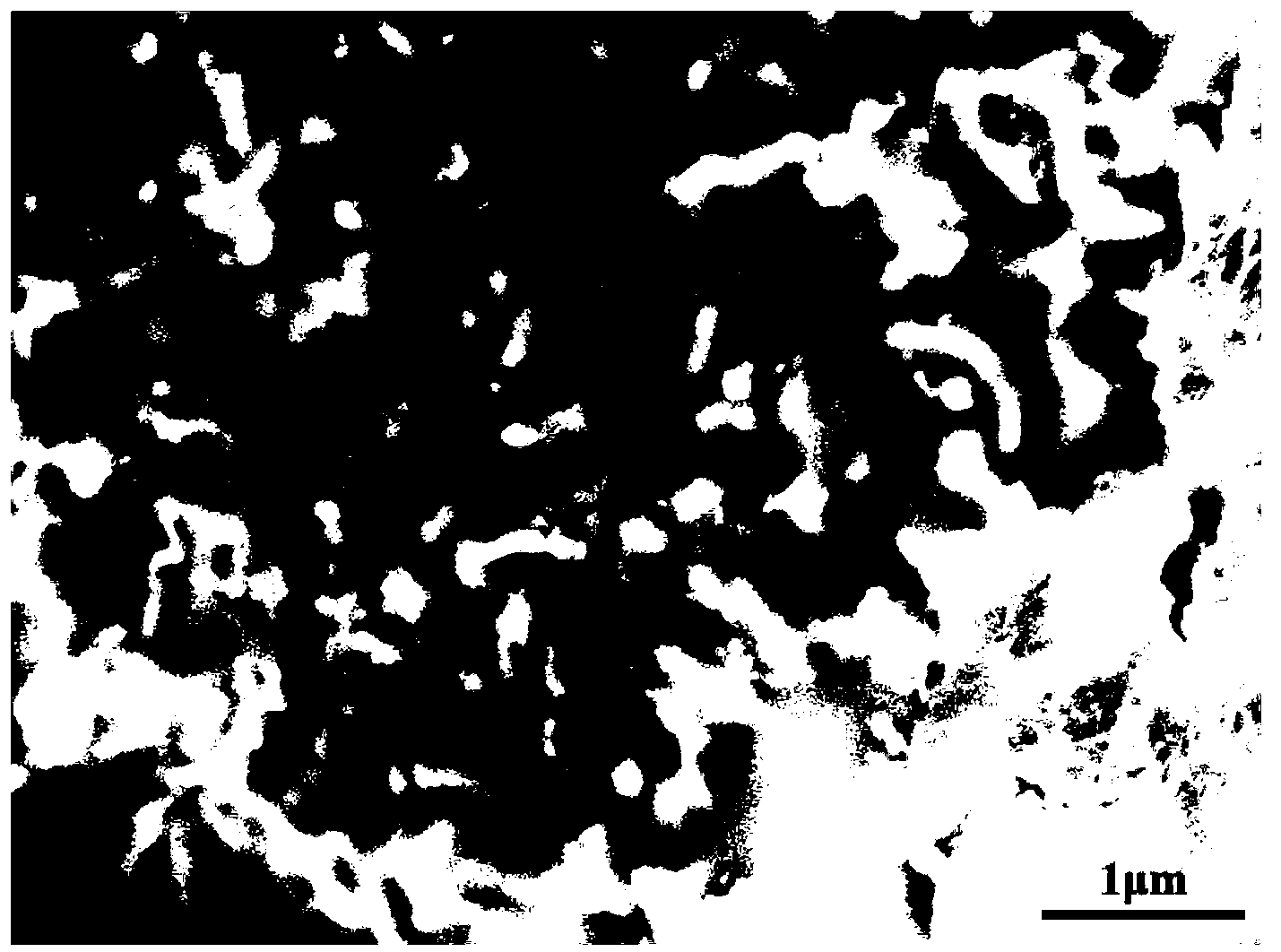

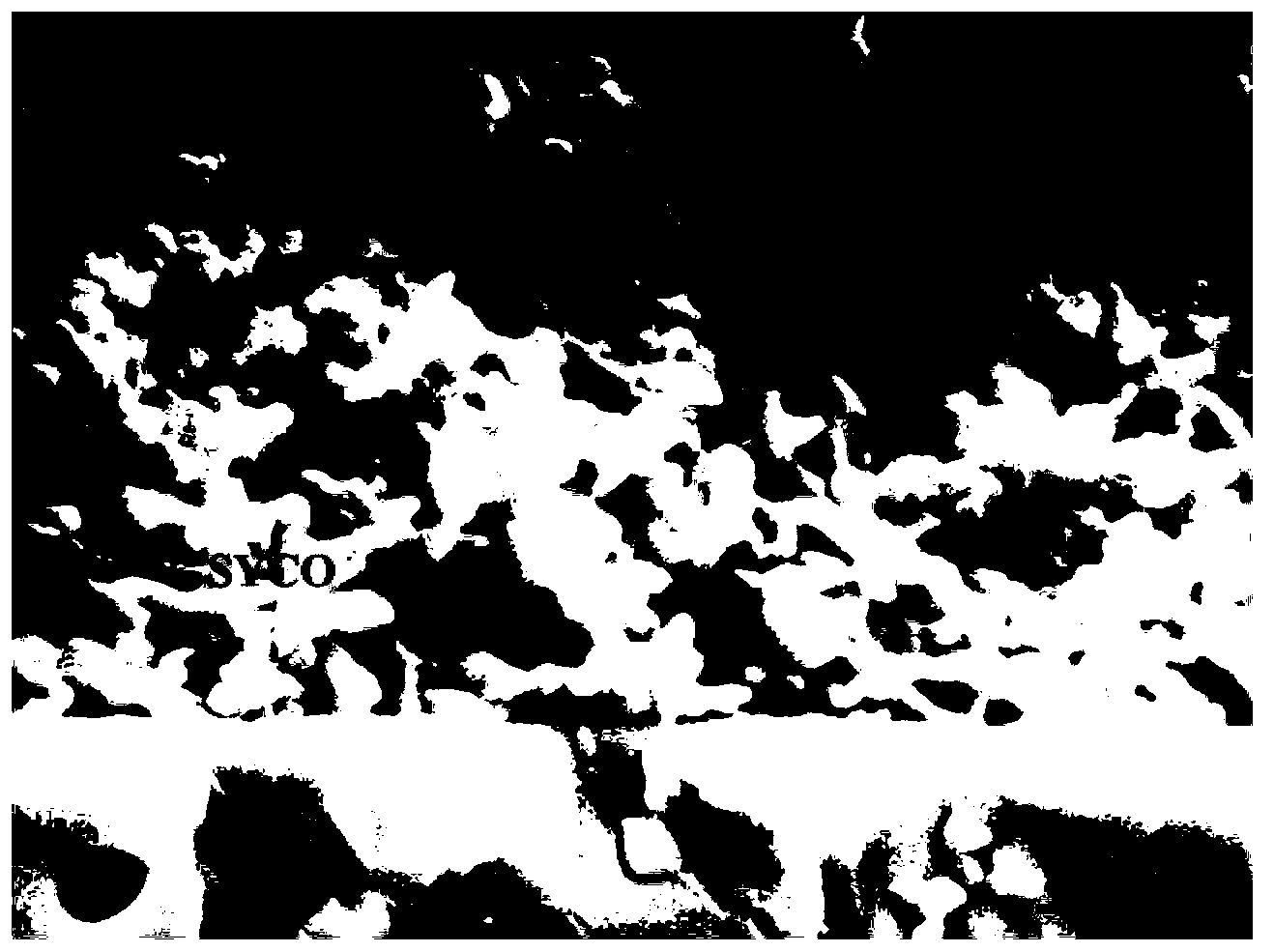

[0021] Specific embodiment 1: The chemical formula of the one-dimensional SYCO cathode material in this embodiment is Sr 1-x Y x CoO 3-δ , where 0≤x≤1, the structure is one-dimensional nanofibers.

[0022] In this embodiment, the one-dimensional nanofibrous cathode material Sr 1-x Y x CoO 3-δ , where x takes 0≤x≤1, and where δ takes 0≤δ≤0.5, which is a perovskite structure material. The diameter of the one-dimensional nanofibrous cathode material is 200-300nm.

specific Embodiment approach 2

[0023] Specific embodiment two: the preparation method of the one-dimensional SYCO cathode material of this embodiment is implemented according to the following steps:

[0024] 1. According to the chemical formula Sr 1-x Y x CoO 3-δ , where 0≤x≤1, according to the molar ratio of Sr element, Y element and Co element as 1-x:x:1, respectively weigh strontium nitrate, yttrium nitrate and cobalt nitrate, then add strontium nitrate, yttrium nitrate and cobalt nitrate into N,N-dimethylformamide, magnetically stirred at room temperature until strontium nitrate, yttrium nitrate and cobalt nitrate are completely dissolved, and polyvinylpyrrolidone is added to stir to obtain an electrospinning precursor solution, and then electrospun to obtain nanofibers;

[0025] 2. Raise the temperature of nanofibers to 300°C at a rate of 2°C / min-10°C / min, sinter at a constant temperature for 1-2h, then continue to heat up to 700-1000°C, and continue sintering for 1-2h to obtain a one-dimensional SYC...

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 2 in that the total mass concentration of yttrium nitrate, strontium nitrate and cobalt nitrate in the electrospinning precursor solution described in step 1 is 15%. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com