Composite salt-tolerant hydrophobic associated amphoteric flocculant and preparation method thereof

An amphoteric flocculant and hydrophobic association technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as environmental pollution, complicated post-treatment, narrow application range, etc., achieve high flocculation performance, excellent salt resistance performance, expand The effect of the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

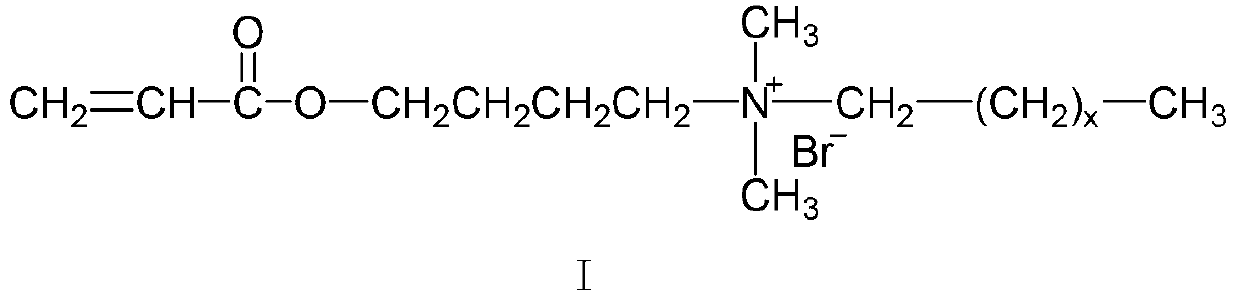

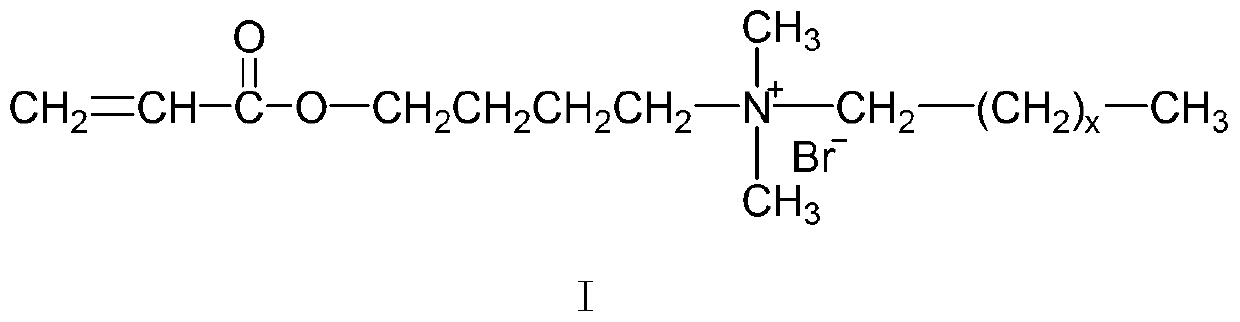

[0027] Embodiment 1, the synthesis of cationic hydrophobic monomer (DMABA)

[0028] In the three-necked flask, add N, N-dimethylacryloyloxybutylamine, n-bromoalkane and acetone in a molar ratio of 1:1:2 in sequence, stir and react at 45°C for 48 hours, and after cooling to room temperature, Wash three times with anhydrous ether, recrystallize twice with ethyl acetate, and dry in vacuum to obtain cationic hydrophobic monomer (DMABA).

[0029] N,N-Dimethacryloyloxybutyl dodecyl ammonium bromide (DMABA12) is obtained when the n-bromoalkane is brominated with n-dodecane;

[0030] N,N-Dimethacryloyloxybutyltetradecylammonium bromide (DMABA14) is obtained when the n-bromoalkane is brominated with n-tetradecane;

[0031] N,N-Dimethacryloyloxybutylhexadecylammonium bromide (DMABA16) can be obtained when n-bromoalkane is brominated with n-hexadecane.

Embodiment 2

[0032] Example 2. Preparation of compound salt-tolerant hydrophobic associative amphoteric flocculant

[0033] In a four-neck reaction flask equipped with condensed water, mechanical stirring and nitrogen inlet, acrylamide (AM), acrylic acid (AA) and N,N-dimethylacryloyloxybutyl dodecyl ammonium bromide (DMABA12 ) is dissolved in an aqueous solution of aluminum trichloride (monomer concentration is 5wt%) according to a molar ratio of 94:3:3, and the pH of the system is adjusted to about 3.0 in the reaction solution. Nitrogen was passed for 30 minutes before the reaction to remove the oxygen in the system, the temperature was raised to 30°C, and 2,2-azo[2-(2-imidazolin-2-yl)propane]dihydro Chloride initiator (VA-044 initiator), polymerization time 24h. That is, the composite salt-tolerant hydrophobic association amphoteric flocculant is obtained.

[0034] The properties of the obtained composite salt-tolerant hydrophobic association amphoteric flocculant solution are as follo...

Embodiment 3

[0043] Acrylamide (AM), acrylic acid (AA) and N,N-dimethylacryloyloxybutylhexadecylammonium bromide (DMABA16 ) is dissolved in an aqueous solution of aluminum trichloride (monomer concentration is 8wt%) according to a molar ratio of 8:1:1, and the pH of the reaction solution is adjusted to about 3.0. Nitrogen was passed for 30 minutes before the reaction to remove oxygen in the system, the temperature was raised to 60°C, and V-501 initiator accounting for 0.02% of the total molar weight of the monomers was added, and the polymerization time was 6 hours. That is, the composite salt-tolerant hydrophobic association amphoteric flocculant is obtained.

[0044] The properties of the obtained composite salt-tolerant hydrophobic association amphoteric flocculant solution are as follows:

[0045] 30℃, shear rate 10s -1 At this time, the apparent viscosity of the polymer solution with a concentration of 0.5g / dL is 50mPa·s, and the viscosity of the polymer solution with a concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com