Inductively coupled plasma-atomic emission spectrometry (ICP-AES) method for testing chemical components of blue phosphors of plasma display panel (PDP)

A technology of ICP-AES and blue phosphor, which is applied in thermal excitation analysis, material excitation analysis, etc., can solve the problems of high price, few batches, and high cost, and achieve small matrix effect, good measurement accuracy, and detection limit low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

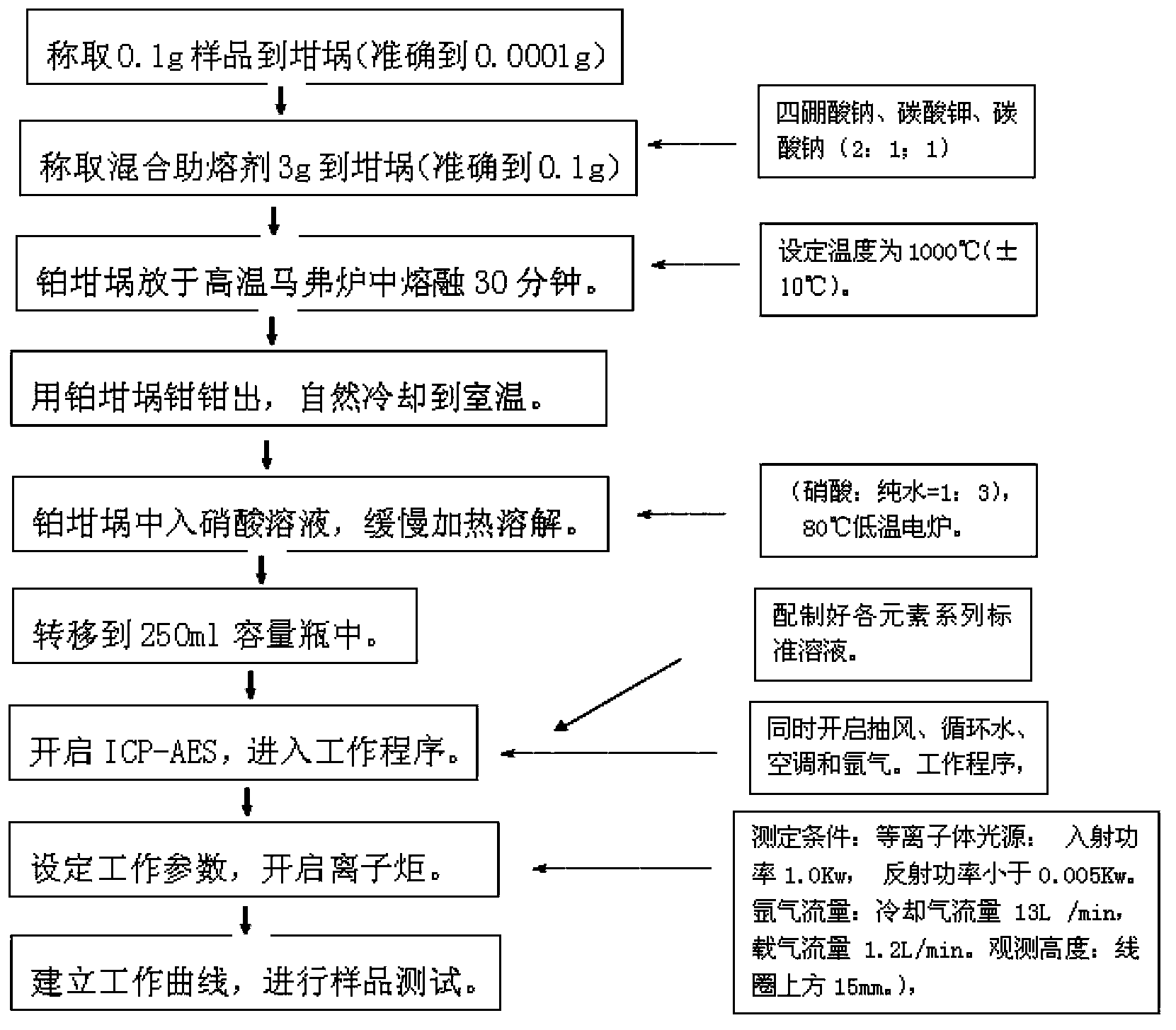

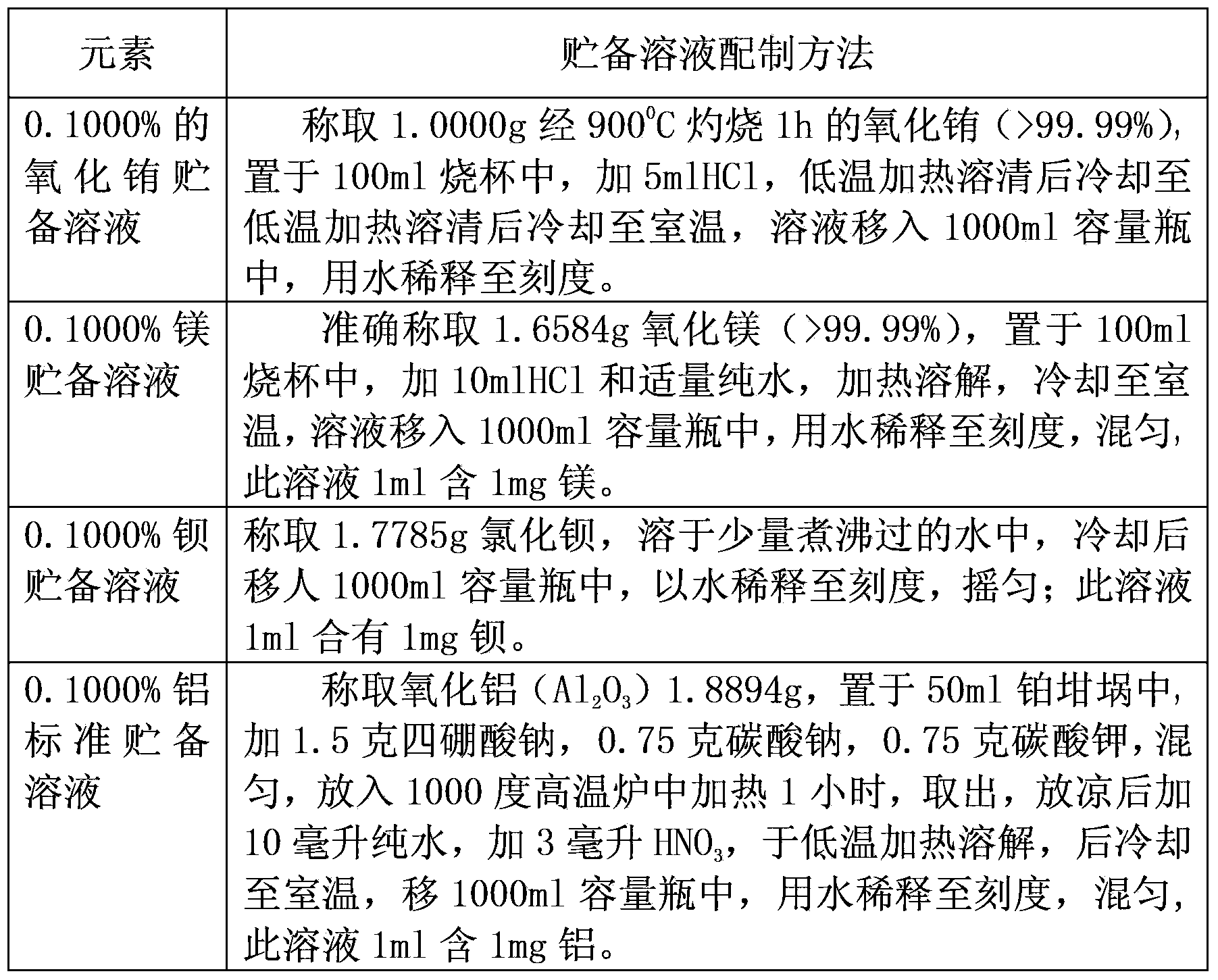

[0021] Step 1: Weigh 0.1g of PDP blue phosphor, weigh 6g of sodium tetraborate:potassium carbonate:sodium carbonate with a mass ratio of 2:1:1 as a mixed flux, mix with PDP blue phosphor and pour into a platinum crucible middle;

[0022] Step 2: Put the platinum crucible in a high-temperature muffle furnace and turn on the power, set the temperature at 1000°C (±10°C), melt at this temperature for 30 minutes, cool to room temperature, and obtain the mixture;

[0023] Step 3: Add nitric acid to the platinum crucible: a nitric acid solution with a mass ratio of pure water of 1:3, heat slowly on a low-temperature electric furnace at 80°C, transfer the mixture to a 250ml volumetric flask after the mixture in the platinum crucible is dissolved, and prepare the elements at the same time A series of standard solutions;

[0024] Step 4: Turn on the ICP-AES, turn on the ventilation, circulating water, air conditioner and argon gas at the same time, enter the working procedure, set the ...

Embodiment 2

[0032] Step 1: Weigh 0.2g of PDP blue phosphor, weigh 5g of sodium tetraborate:potassium carbonate:sodium carbonate with a mass ratio of 2:1:1 as a mixing flux, mix with PDP blue phosphor and pour into a platinum crucible middle;

[0033] Step 2: Put the platinum crucible in a high-temperature muffle furnace and turn on the power, set the temperature at 1000°C (±10°C), melt at this temperature for 30 minutes, cool to room temperature, and obtain the mixture;

[0034] Step 3: Add nitric acid to the platinum crucible: a nitric acid solution with a mass ratio of pure water of 1:3, heat slowly on a low-temperature electric furnace at 80°C, transfer the mixture to a 250ml volumetric flask after the mixture in the platinum crucible is dissolved, and prepare the elements at the same time A series of standard solutions;

[0035] Step 4: Turn on the ICP-AES, turn on the ventilation, circulating water, air conditioner and argon gas at the same time, enter the working procedure, set the...

Embodiment 3

[0043] Step 1: Weigh 0.15g of PDP blue phosphor, weigh 3g of sodium tetraborate:potassium carbonate:sodium carbonate with a mass ratio of 2:1:1 as a mixed flux, mix with PDP blue phosphor and pour into a platinum crucible middle;

[0044] Step 2: Put the platinum crucible in a high-temperature muffle furnace and turn on the power, set the temperature at 1000°C (±10°C), melt at this temperature for 30 minutes, cool to room temperature, and obtain the mixture;

[0045]Step 3: Add nitric acid to the platinum crucible: a nitric acid solution with a mass ratio of pure water of 1:3, heat slowly on a low-temperature electric furnace at 80°C, transfer the mixture to a 250ml volumetric flask after the mixture in the platinum crucible is dissolved, and prepare the elements at the same time A series of standard solutions;

[0046] Step 4: Turn on the ICP-AES, turn on the ventilation, circulating water, air conditioner and argon gas at the same time, enter the working procedure, set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com