High-strength, high-toughness and rain-resistant infrared cement heat-preserving decorative board

A thermal insulation decorative board and high toughness technology, applied in the field of cement decorative board and cement decorative board of building materials, can solve the problems of deflagration, improper hydrophobic treatment or waterproof treatment, and decreased thermal insulation performance, so as to reduce the weight per unit volume, The effect of increasing the rain resistance and improving the bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

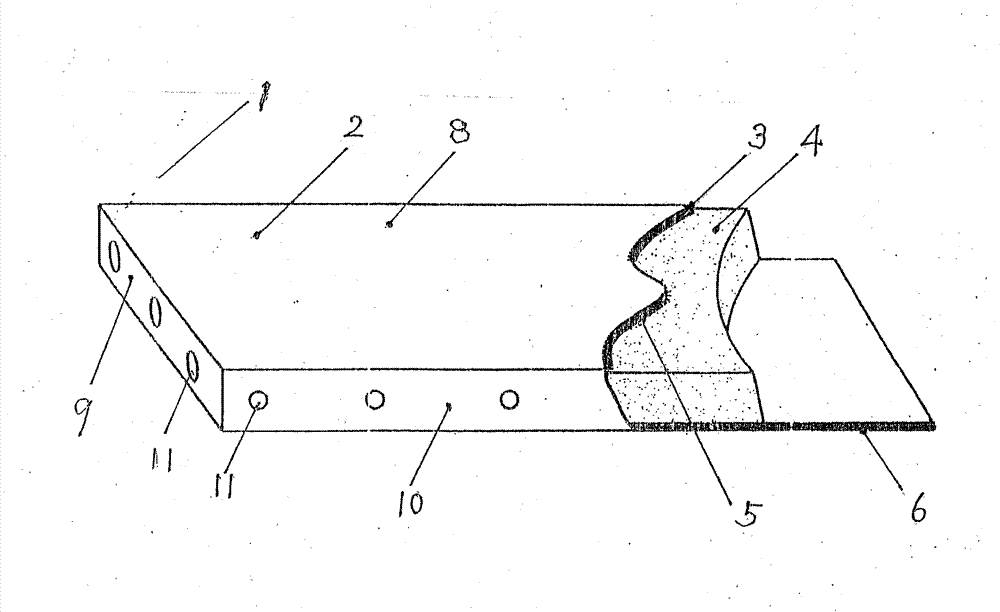

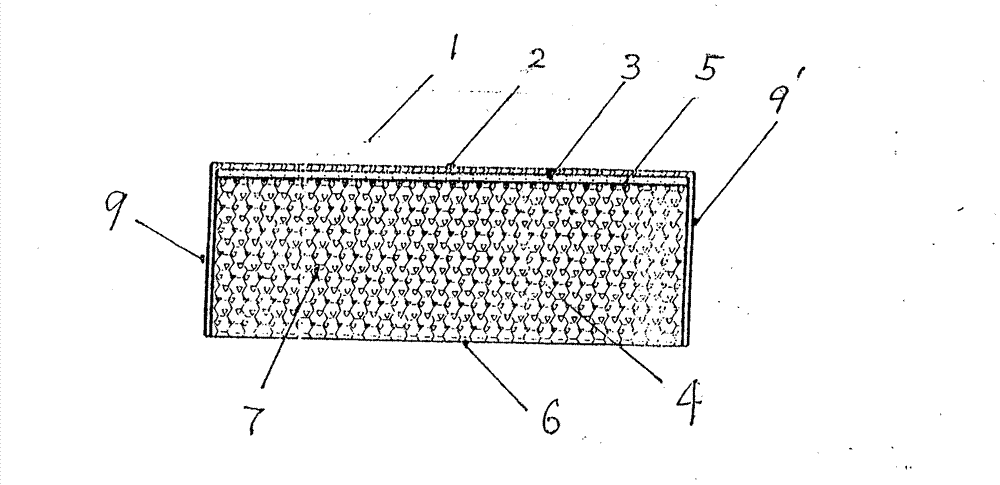

[0037] Attached below figure 1 And attached figure 2 and Examples further describe the present invention; the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following examples. Such as figure 1 and figure 2 As shown, the high-strength, high-toughness and rain-resistant infrared cement thermal insulation decorative board 1 of the present invention is composed of a convex aluminum foil decorative protective sheath layer 2, an infrared cement decorative board core board layer 4 and an adhesive layer 3. It is different from The prior art lies in: the above-mentioned high-strength, high-toughness and rain-resistant infrared cement thermal insulation decorative board 1 is provided with a convex aluminum foil decorative protective sheath layer 2, and an infrared cement decorative board is arranged inside the conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com