An acylase that cleaves cpc to produce 7-aca in one step and its polynucleotide

A technology of acylase and acylase activity, which can be used in hydrolase, bulk chemical production, microorganisms, etc., and can solve the problems of low substrate specificity, poor substrate tolerance, and low conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

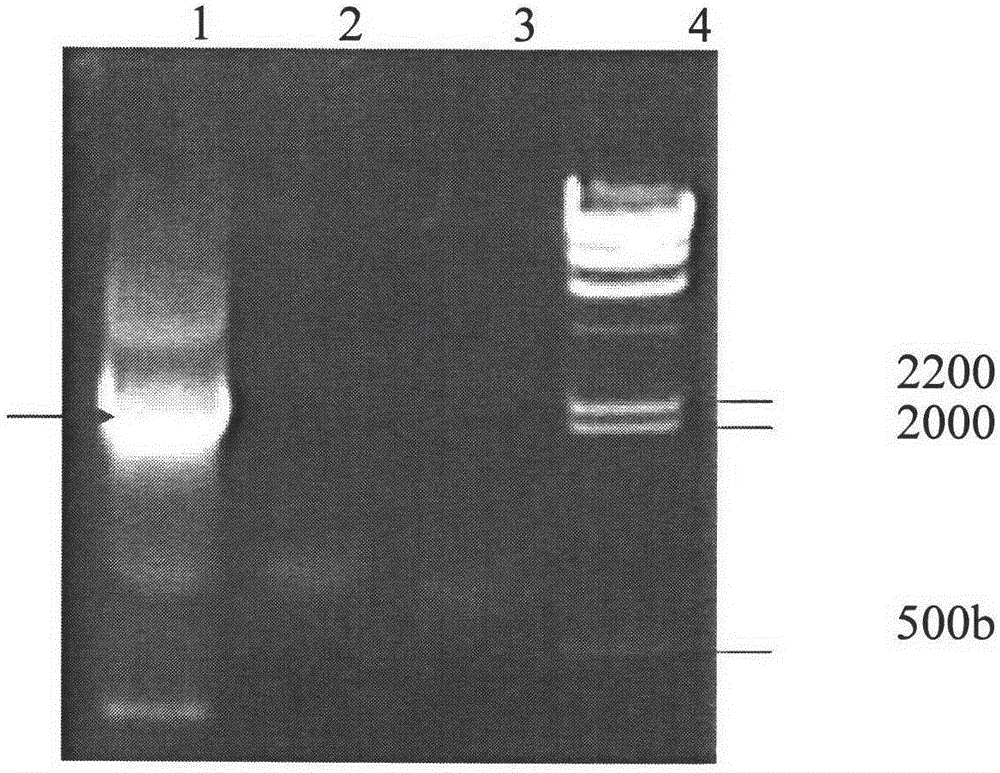

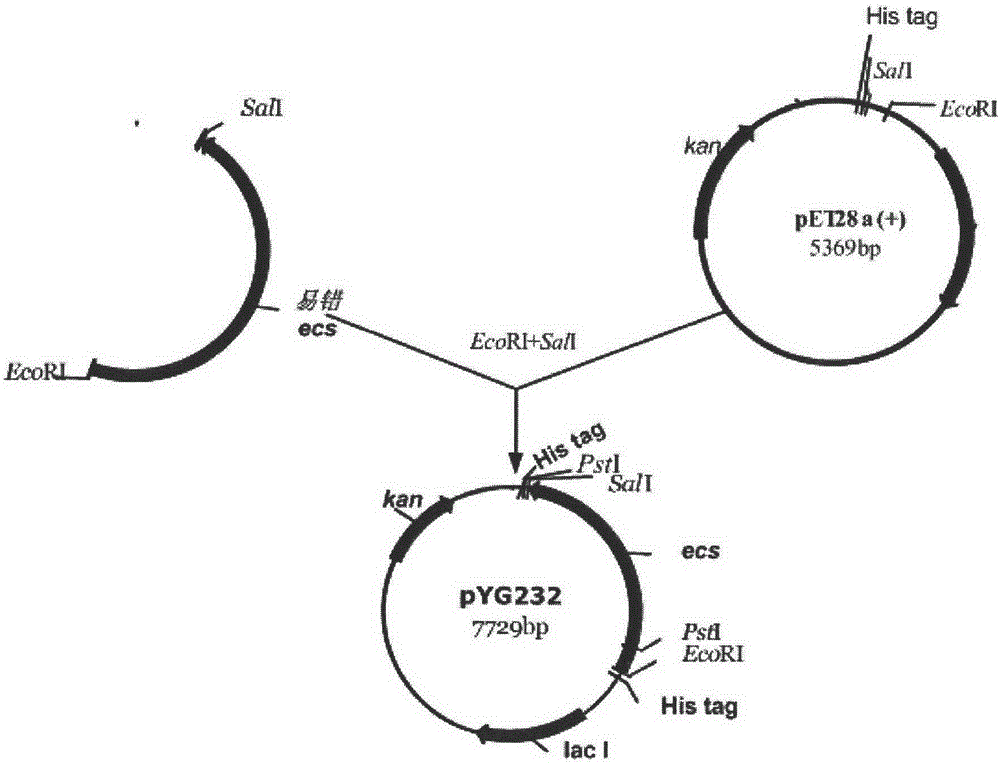

[0054] Example 1. Construction of error-prone PCR and product expression plasmids for the starting sequence

[0055] 1.1 Perform error-prone PCR on the starting sequence ecs gene

[0056] ECS stands for CPC Acylase. Wherein, the starting sequence is obtained by connecting segmented PCR products, and its gene sequence is shown in Figure 8 pyg232. When using DNA polymerase to amplify the target gene, by adjusting the reaction conditions, increasing the concentration of magnesium ions or adding manganese ions, using low-fidelity DNA polymerase to change the mutation frequency during the amplification process, so as to increase the mutation frequency at a certain frequency. Randomly introduce mutations into the target gene to obtain random mutants of protein molecules. The PCR reaction system used is as follows:

[0057]

[0058] The sequences of primers P1 and P2 are:

[0059] P 1 : 5'-GCTT GTC GAC TCTAGATCAGTGGTG-3' (the underlined part is the SalI restriction site); ...

Embodiment 2

[0064] Example 2. Primary screening of transformants

[0065] 2.1 Transformant cell culture and protein expression

[0066] Select the engineered bacterium transfer test tube of construction and cultivate overnight, then transfer to the shaking flask that 250ml LB liquid medium is housed with the inoculum of 2% (V / V), and the concentration of kanamycin in the LB medium is 10~50 μ g / ml, cultured at 37°C, 220 rpm for 3 hours;

[0067] Then add IPTG to make the final concentration of IPTG in the medium reach 0.6 mmol, 25°C, 220 rpm, and culture for another 16 hours;

[0068] Centrifuge the bacterial cells at a speed of 8000 rpm in a low-temperature centrifuge.

[0069] 2.2 Primary screening of transformants

[0070] Suspend the collected cells with 3ml of 0.1mmol Tris-HCl, take 1ml of concentrated cells and 0.1mg of CPC in a water bath at 25°C, 28°C, 37°C, pH9.6 and pH8.0 respectively for 1h, centrifuge at 13200r / min for 5min Take the supernatant, and measure the absorbance ...

Embodiment 3

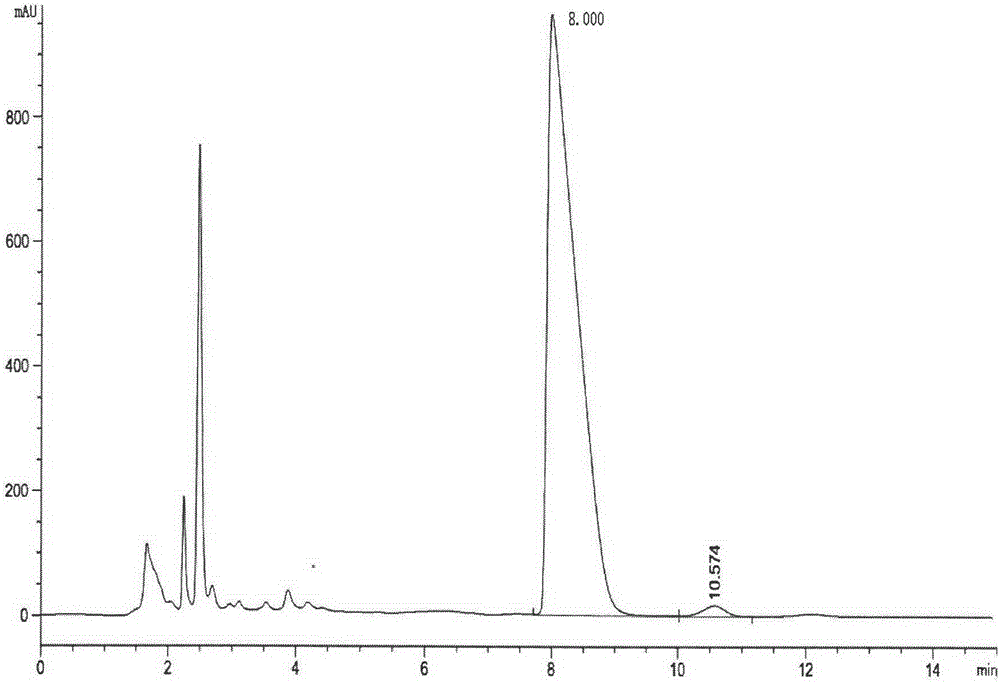

[0071] Example 3. Re-screening of highly active transformants

[0072] 3.1 Recultivate the 63 highly active transformants obtained from the primary screening

[0073] 1) 250ml induced expression culture (the induced expression culture obtained in the embodiment 2 step 2.1), centrifuged (8000rpm, 10min) to obtain the thalline, the thalline of the harvest is diluted with 5ml P buffer solution (pH8.0, 100 times) 1M disodium hydrogen phosphate and sodium dihydrogen phosphate mixture) suspension, ultrasonic crushing (crushing time 5s / interval time 5s, 500W, ultrasonic crushing 10min).

[0074] 2) Centrifugation and sedimentation: after crushing, centrifuge at 4°C at a speed of 8000 rpm (Hitachi Himac CR21G refrigerated high-speed centrifuge, rotor is R12A), and precipitate cell debris.

[0075] 3) Separation and purification: the obtained supernatant (with his tag) was placed in a 100ml beaker, and separated and purified with a nickel column. The specific steps are:

[0076] Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com