Boron-doped graphene and preparation method thereof

A graphene and boron doping technology, which is applied in the field of boron-doped graphene and its preparation, can solve the problems of high oxygen content, inability to give full play to its advantages, low boron content of boron-doped graphene, etc., and achieve high boron content , Excellent mechanical strength, easy to control the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

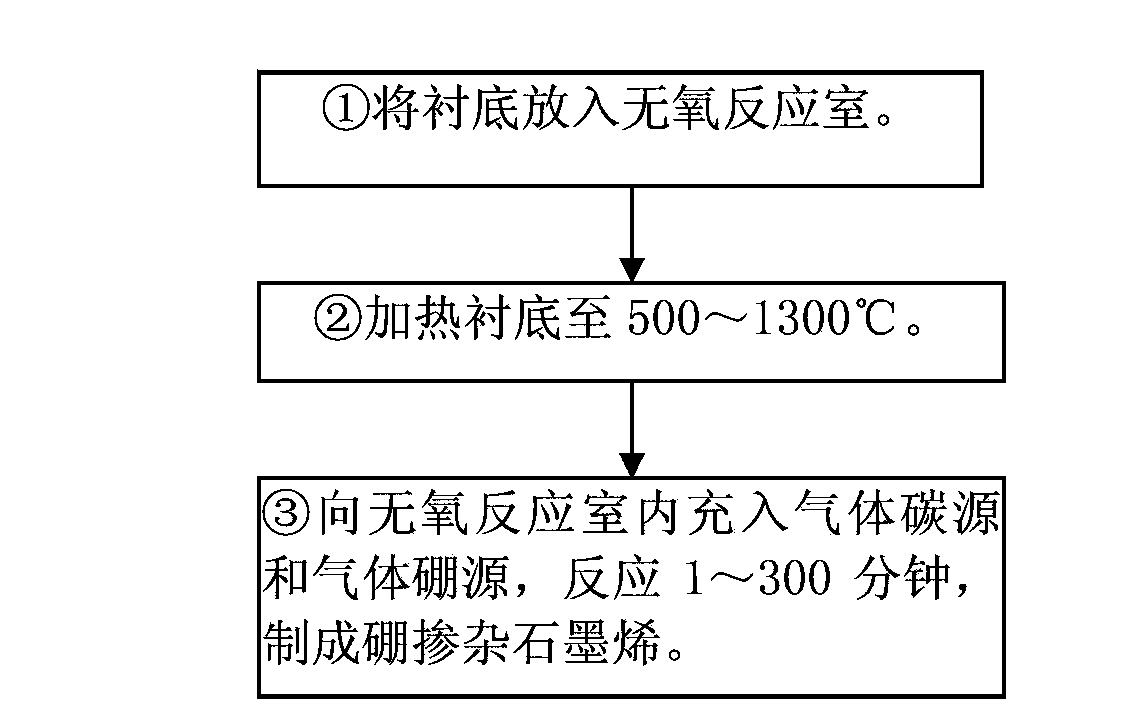

[0024] Combine below figure 1 The method for preparing boron-doped graphene of the present invention will be described. Such as figure 1 as shown, figure 1 It is a flowchart of the preparation method of boron-doped graphene of the present invention. The preparation method of boron-doped graphene of the present invention comprises the following steps:

[0025] ① Put the substrate into the anaerobic reaction chamber.

[0026] Before the substrate is placed in the anaerobic reaction chamber, preferably, the substrate is ultrasonically cleaned with deionized water, ethanol, and acetone, and then dried. Substrates include copper, iron or nickel foil. Put the substrate into the anaerobic reaction chamber, fill it with nitrogen, and use the mechanical pump, Roots pump and molecular pump in sequence to pump the chamber pressure of the anaerobic reaction chamber to 10 -3 Below Pa, keep it for 1 to 30 minutes, stop nitrogen filling, turn off the molecular pump, and start heating. ...

Embodiment 1

[0033] 1. Put the substrate into the reaction chamber, the substrate is copper foil, fill with nitrogen, and use mechanical pump, Roots pump and molecular pump to pump the reaction chamber to 10 -3 Pa below, and after maintaining for 30 minutes, stop filling nitrogen, turn off the molecular pump, and start heating.

[0034] 2. When the temperature of the copper foil reaches 1100°C, start to fill the reaction chamber with a mixture of gaseous carbon source and gaseous boron source. The gaseous carbon source is methane, and the gaseous boron source is boron trichloride. Keep the temperature constant and start to generate Boron doped graphene. Among them, gaseous carbon source flow: 150ml / min, gaseous boron source flow: 200ml / min.

[0035] 3. After reacting for 200 minutes, stop heating the copper foil and cool to room temperature to obtain boron-doped graphene. That is, the boron-doped graphene of the present invention is prepared.

Embodiment 2

[0037] 1. Put the substrate into the reaction chamber, the substrate is iron foil, fill with nitrogen, and use mechanical pump, Roots pump and molecular pump to pump the reaction chamber to 10 -3 Pa below, and after keeping for 20 minutes, stop filling nitrogen, turn off the molecular pump, and start heating.

[0038] 2. When the temperature of the iron foil reaches 1200°C, start to fill the reaction chamber with a mixture of gaseous carbon source and gaseous boron source. The gaseous carbon source is ethane, and the gaseous boron source is boron trichloride. Keep the temperature constant and start Generate boron doped graphene. Among them, gaseous carbon source flow: 180ml / min, gaseous boron source flow: 220ml / min.

[0039] 3. After reacting for 260 minutes, stop heating the iron foil and cool it down to room temperature to obtain boron-doped graphene. That is, the boron-doped graphene of the present invention is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com