A kind of preparation method of lithium iron phosphate cathode material

A cathode material, lithium iron phosphate technology, used in battery electrodes, electrical components, circuits, etc., can solve the problems of reduced tap density, insignificant effect, and impact on processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

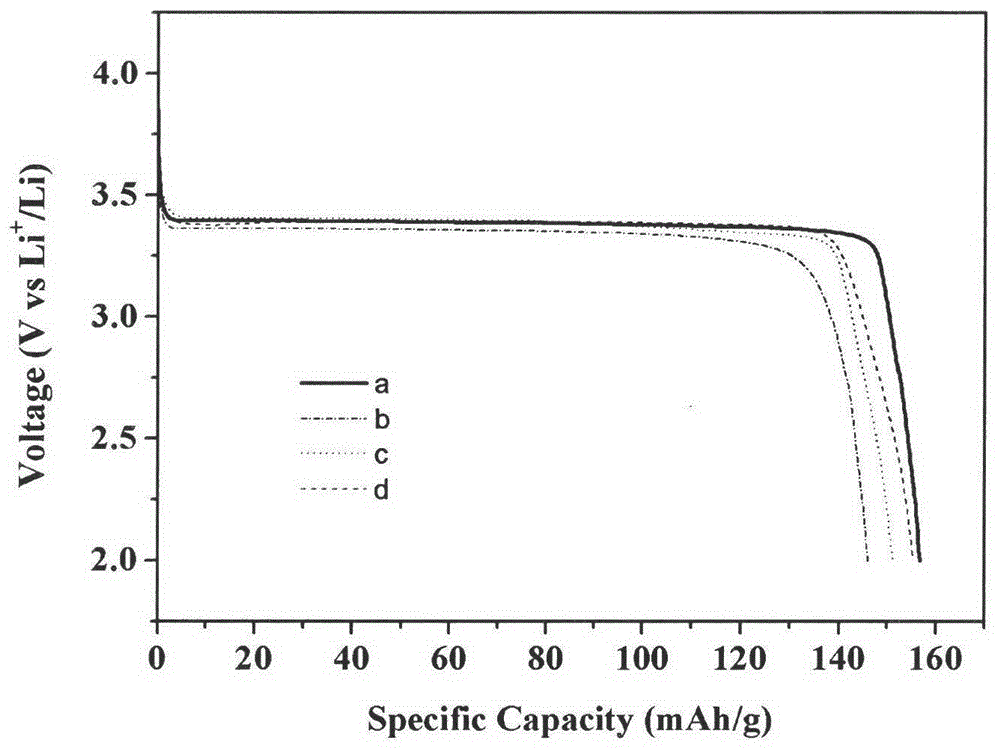

Embodiment 1

[0023] 1) Weigh lithium carbonate, ferrous oxalate, ammonium dihydrogen phosphate, and sucrose according to the molar ratio Li:Fe:P:C=1.02:1:1:0.2, and carry out ball milling dispersion treatment with alcohol as a dispersant for 5 hours, and then carry out The precursor was obtained by vacuum drying; the dry precursor obtained above was placed in a tube furnace at 550°C and pre-fired under the protection of nitrogen. The heating rate was 5°C / min, and the holding time was 5 hours. Natural cooling down to room temperature , coarsely pulverize the calcined material;

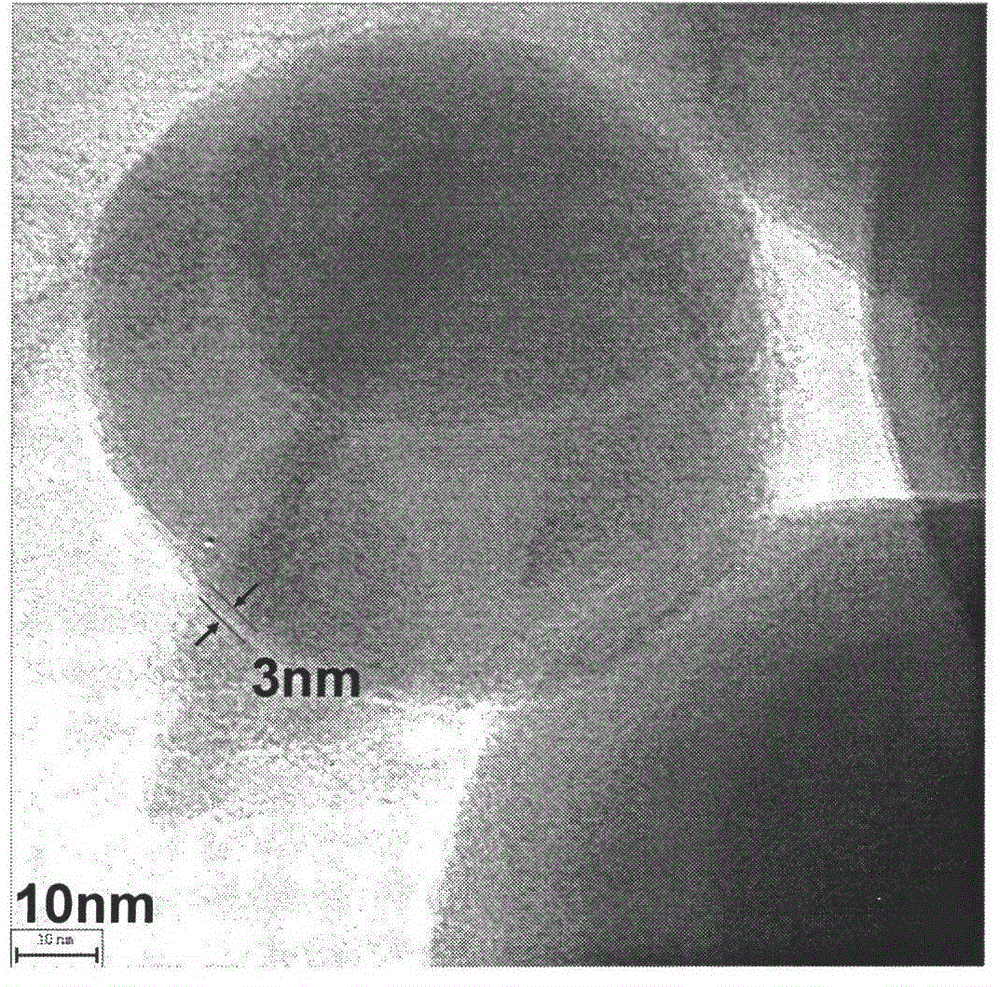

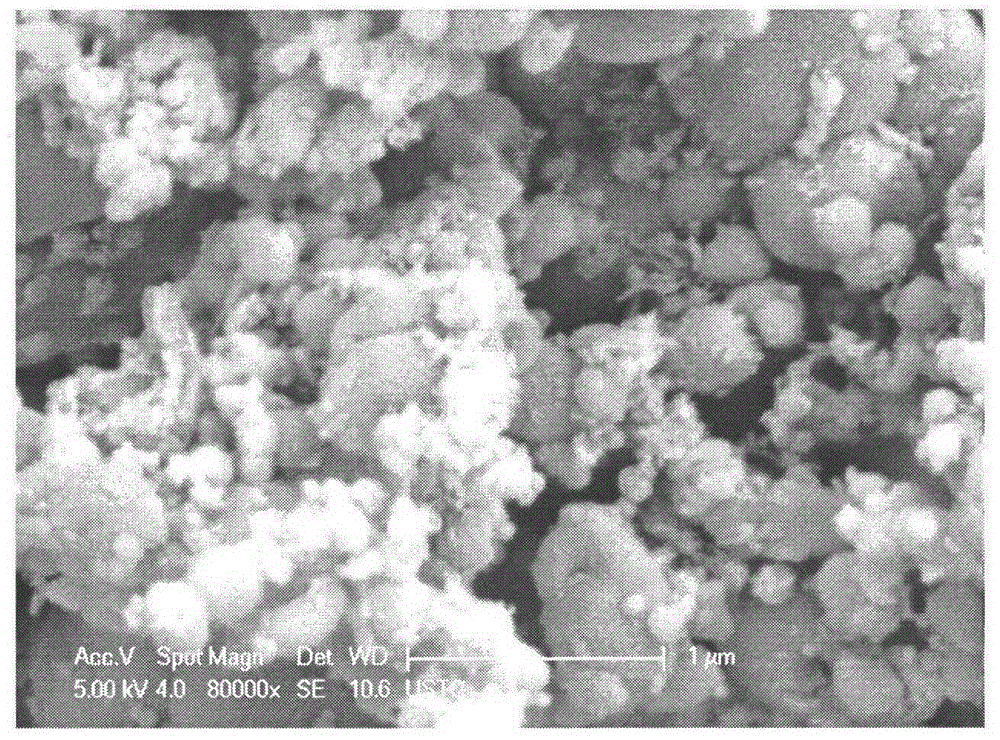

[0024] 2) Place the coarsely pulverized calcined material obtained above in a tube furnace for secondary sintering, and raise the temperature to 700° C. at a rate of 5° C. / min under the protection of nitrogen, and keep it warm for 10 hours. During the heating process, the nitrogen inlet pressure is 0.15MPa, and the flow rate is 0.1L / min. When the temperature reaches the set temperature, introduce methane gas and mo...

Embodiment 2

[0026] 1) Weigh lithium carbonate, ferrous oxalate, ammonium dihydrogen phosphate, and glucose according to the molar ratio Li:Fe:P:C=1.02:1:1:0.3, and use acetone as a dispersant to carry out ball milling dispersion treatment for 5 hours, and then carry out The precursor was obtained by vacuum drying; the dry precursor obtained above was placed in a tube furnace at 550°C and pre-fired under the protection of argon. The heating rate was 5°C / min, the holding time was 5 hours, and the natural cooling decreased to At room temperature, coarsely pulverize the calcined material;

[0027] 2) Place the coarsely pulverized calcined material obtained above in a tube furnace for secondary sintering, and raise the temperature to 720° C. at a rate of 5° C. / min under the protection of argon, and keep it warm for 10 hours. During the heating process, the argon inlet pressure is 0.15MPa, and the flow rate is 0.1L / min. When the temperature reaches the set temperature, introduce ethane gas and...

Embodiment 3

[0029] 1) Weigh lithium carbonate, ferrous oxalate, ammonium dihydrogen phosphate, and phenolic resin according to the molar ratio Li:Fe:P:C=1.02:1:1:0.35, and carry out ball milling dispersion treatment with alcohol as a dispersant for 5 hours, and then Carry out vacuum drying to obtain the precursor; place the dry precursor obtained above in a tube furnace at 550°C and pre-burn under the protection of nitrogen. The heating rate is 5°C / min, the holding time is 5 hours, and the natural cooling is reduced to At room temperature, coarsely pulverize the calcined material;

[0030] 2) Place the coarsely pulverized calcined material obtained above in a tube furnace for secondary sintering, and raise the temperature to 740° C. at a rate of 5° C. / min under the protection of nitrogen, and keep it warm for 10 hours. During the heating process, the inlet pressure of nitrogen gas is 0.15MPa, and the flow rate is 0.1L / min. When the temperature reaches the set temperature, introduce metha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com