Alcohol-soluble conjugate organic micromolecular material for cathode interface of solar cell, and preparation method and purpose thereof

A technology of interface material and cathode interface layer, applied in the field of solar cell materials, can solve the problems of increasing device manufacturing cost and unfavorable preparation of flexible devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

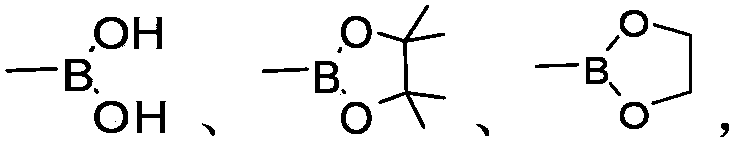

Method used

Image

Examples

preparation example Construction

[0173] The film can optionally be prepared by conventional techniques in the art, such as spin coating, doctor blade, printing and other processes. In a preferred example of the present invention, the preparation method of the film comprises the following steps:

[0174] providing a solution in which the compound of formula I is dissolved; and

[0175] A surface is provided on which the solution is film-formed.

[0176] In another preferred embodiment, the solution is prepared by dissolving the compound of formula I in an organic solvent. The organic solvent is preferably an alcohol solvent, including (but not limited to): methanol, ethanol, or a combination thereof; more preferably, the organic solvent is methanol.

[0177] The surface type is not particularly limited, and can be the surface of any product, such as the surface of organic solar cell electrodes, organic light emitting diodes, organic field effect transistor electrodes and other product surfaces.

[0178] In ...

Embodiment 1

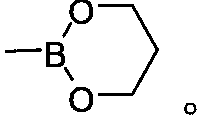

[0224] The synthesis of embodiment 1FPF-N

[0225]

[0226] The preparation method of FPF-N includes the following steps (1) to (3):

[0227] (1) Synthesis of 9,9-bis(2-N,N-dimethylaminoethyl)-2-bromofluorene:

[0228]

[0229] Under nitrogen protection, add 2-bromofluorene (7.35g, 30mmol), N,N-dimethyl-2-chloroethylamine hydrochloride (17.28g, 120mmol) and potassium hydroxide in addition to oxygen to a 500mL two-necked flask Aqueous solution (120mL, 50%) and toluene (100mL) were heated to 85°C for 12 hours. After the reaction, cool to room temperature, add water, extract with dichloromethane, combine the organic phases, wash with saturated brine and water successively, dry over anhydrous sodium sulfate, filter, and remove the organic solvent by rotary evaporation. The solid was separated by silica gel column chromatography using dichloromethane:methanol:triethylamine (V:V:V=10:1:0.1) as the eluent to obtain a white solid 9,9-bis(2-N,N- Dimethylaminoethyl)-2-bromofluo...

Embodiment 2

[0239] The synthesis of embodiment 2FBF-N

[0240]

[0241] The preparation method of FBF-N includes the following steps (1) to (3):

[0242] (1) Synthesis of 9,9-bis(2-N,N-dimethylaminoethyl)-2-bromofluorene:

[0243] The synthesis process is detailed in step (1) in Example 1.

[0244] (2) Synthesis of 9,9-bis(2-N,N-dimethylaminoethyl)-2-fluorene-pinacol borate:

[0245] The synthesis process is detailed in step (2) in Example 1.

[0246] (3) Synthesis of FBF-N:

[0247]

[0248] Add 4,7-dibromobenzo[c][1,2,5]thiadiazole (0.29g, 1mmol), 9,9-bis(2-N,N-dimethylamino Ethyl)-2-fluorene-pinacol borate (1.74g, 4mmol), potassium carbonate (2.72g, 20mmol) and tetrakistriphenylphosphopalladium (34mg, 0.03mmol), pump nitrogen three times, add Peroxygenated toluene and water were refluxed for 24 hours under the protection of nitrogen. After the reaction, cool to room temperature, extract with dichloromethane, combine organic phases, wash with saturated brine and water succes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com