Method for manufacturing magnetic sludge-based active carbon

A technology of activated carbon and sludge, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of difficult recycling of activated carbon, increase in cost, environmental pollution, etc., and achieve easy separation from water. , The effect of reducing production costs and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing sludge-based magnetic activated carbon, the method uses residual sludge from urban sewage treatment plants as the main raw material, and is characterized in that it includes the following processes:

[0030] (1) The remaining sludge from the urban sewage plant was dried in a drying oven at 105° C. (24 hours), and then pulverized with a pulverizer until it passed through a 200-mesh sieve to obtain sludge powder.

[0031] (2) Soak the sludge powder in a mixed solution of ferrous chloride and ferric chloride for 24 hours for activation, then add ammonia water under rapid stirring, and put it in a drying oven at 105°C for drying (48h).

[0032] (3) Put the treated sludge in (2) into the muffle furnace and heat it up to the optimum temperature for carbonization for 45 minutes, activate for 60 minutes at the optimum temperature for activation, and then cool to room temperature

[0033] (4) The material after (3) is cleaned with distilled water, dried, g...

Embodiment 2

[0037] The difference between this embodiment and Example 1 is that step (5) is: perform characterization analysis on the magnetic activated carbon produced in (4), including specific surface area analysis, magnetic force analysis, XRD phase analysis, load magnetic ratio, other steps and implementation Example 1 is the same.

[0038] After testing, the BET specific surface area of magnetic sludge-based activated carbon is 178.0m 2 / g, the external area is 57.77m 2 / g, the surface area of micropores is 120.2m 2 / g; the coercive force is 131.9G, the magnetization is 2.6089emu / g, and the magnetic force is 0.28075emu / g. The phases that can be determined by XRD include graphite, ferric oxide, hematite, iron, iron tartrate, etc. , the mass ratio of the produced sludge-based magnetic activated carbon containing magnetism to the total solid matter is 84.6%.

Embodiment 3

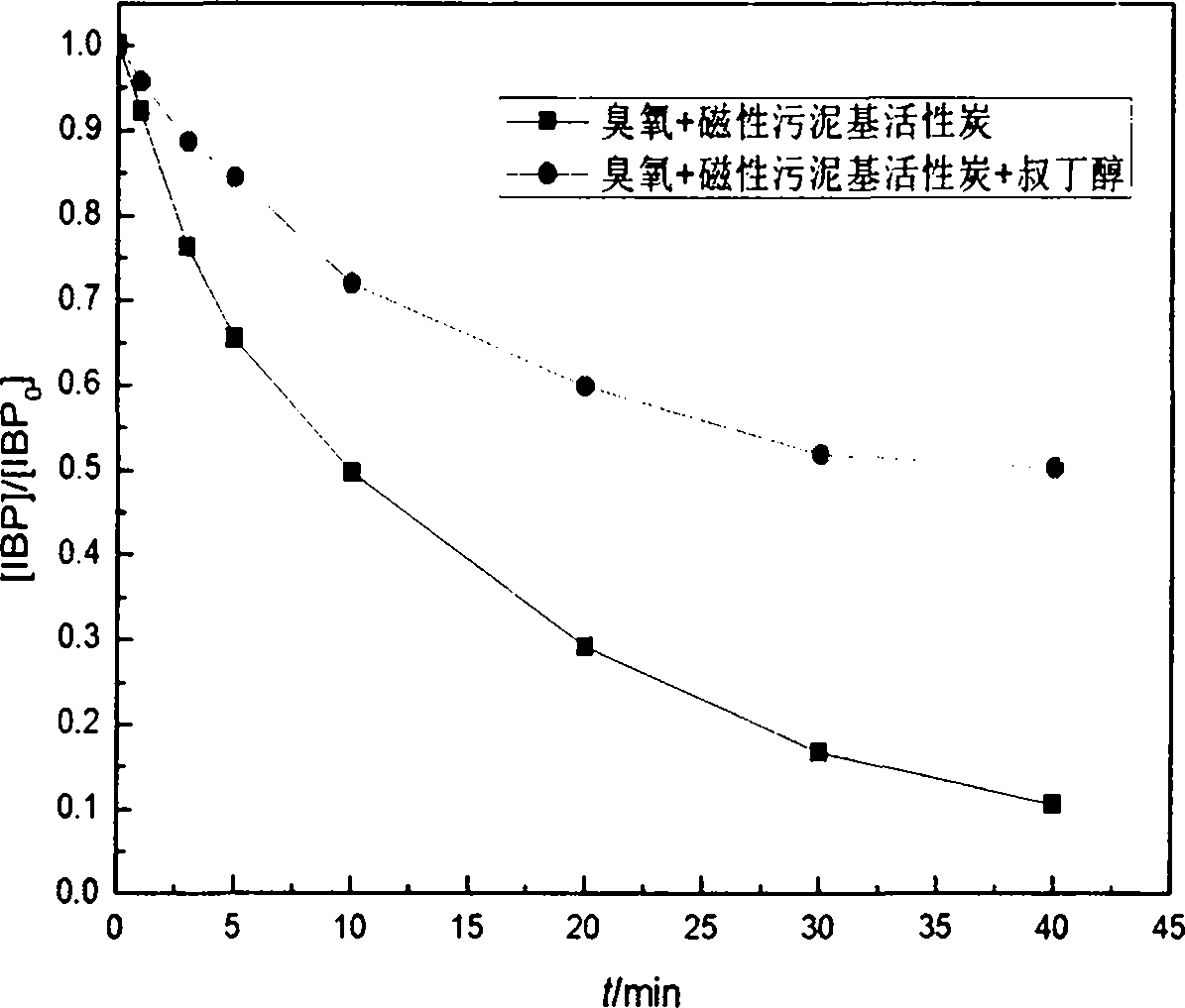

[0040] The difference between this embodiment and embodiment one is that the (5) step is: adding 25 mg / l of magnetic activated carbon and 1.5 mg / l of ozone in the water whose ibuprofen concentration is 700 ug / l, and adding the hydroxyl radical inhibitor simultaneously Tertiary butanol, 0.25mmol / l, other steps are identical with embodiment one.

[0041] After testing, the intervention of tert-butanol largely inhibited the removal effect of magnetic sludge-based activated carbon on ibuprofen, which indicated that magnetic sludge-based activated carbon catalyzed ozone oxidation of ibuprofen followed the mechanism of hydroxyl radical reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com