Reaction separating and coupling apparatus, and technology for preparation of gluconic acid from xylitol crystallization mother liquor

A technology of crystallizing mother liquor and gluconic acid, which is applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc. problems, to achieve the effect of reducing purification steps, simplifying separation steps, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

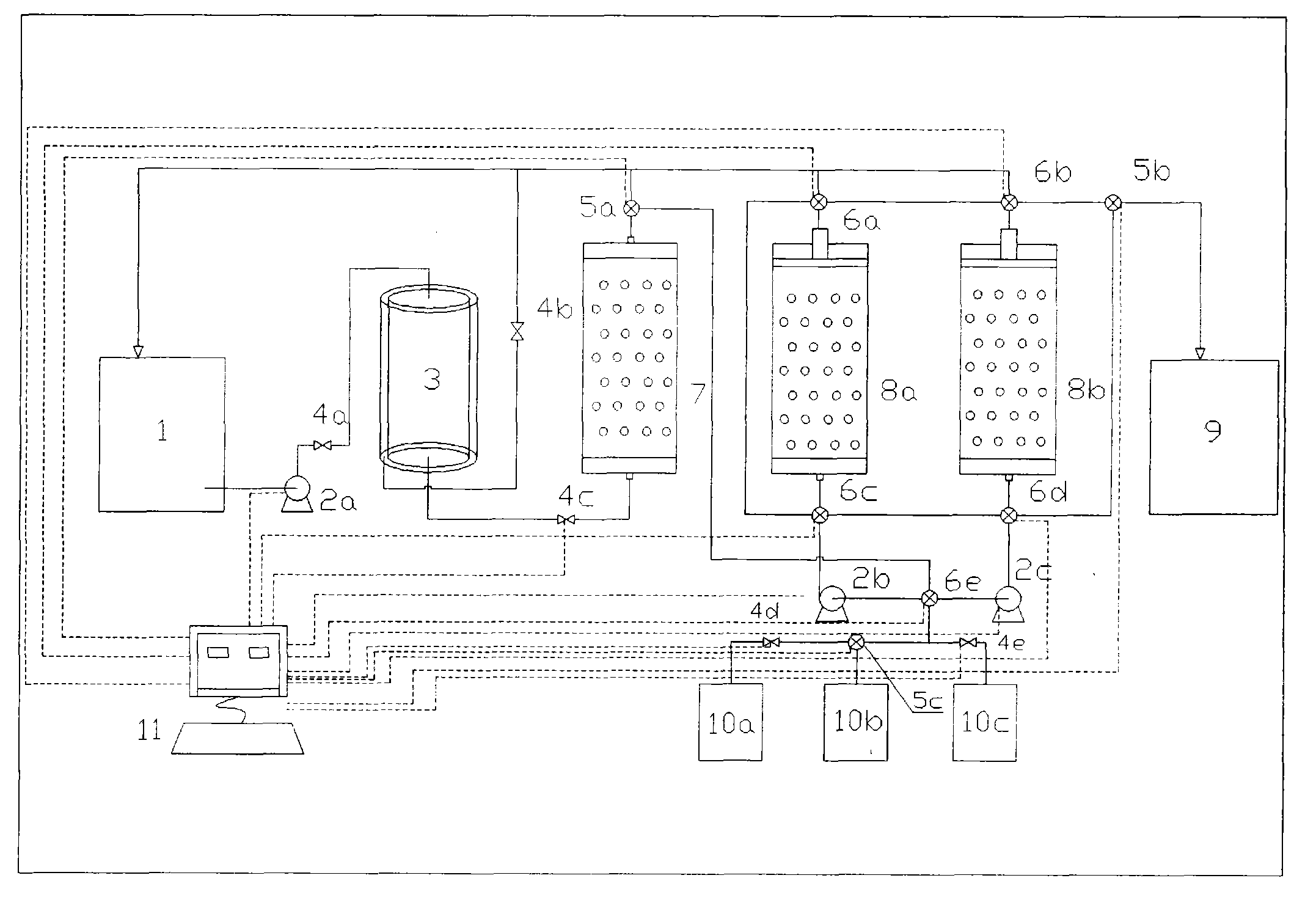

[0034] figure 1 As a specific embodiment of the present invention, as can be seen from the figure, the reaction separation coupling device for preparing gluconic acid from xylitol crystallization mother liquor includes co-immobilized glucose oxidase and catalase column reactor 7, Nanofiltration device 3, two fixed-bed chromatography columns 8, computer control system 11, three transfer pumps 2, raw material liquid storage tank 1, product liquid storage tank 9, eluent liquid storage tank 10, five valves 4, Three three-way valves 5, five four-way valves 6. as attached figure 1 shown.

[0035] The top of the nanofiltration device 3 is connected to the liquid storage tank through the pump 2a, and one end of the bottom liquid outlet (nanofiltration decolorization solution) is connected to the bottom of the co-immobilized glucose oxidase and catalase column reactor 7, and the other end retains The liquid outlet is connected with the circulation main pipeline and connected with th...

Embodiment 2

[0052] First, according to figure 1 device, the nanofiltration membrane with a molecular weight cut-off of 4000Da is placed in the nanofiltration device 3, and the co-immobilized CAT / GOD cross-linked chitosan is filled in the co-immobilized glucose oxidase and catalase column reactor 7 Lysine resin, filled with anion exchange resin D239 in two chromatography columns 8.

[0053]In the second step, through the transfer pump 2a, the xylose crystallization mother liquor enters the nanofiltration device 3, and one end of the nanofiltration device outlet (nanofiltration decolorization solution) is connected to the bottom of the co-immobilized glucose oxidase and catalase column reactor 7 , to provide the xylose crystallization mother liquor that meets the requirements, and the intercepted liquid at the other end is connected to the main circulation pipeline and connected to the raw material liquid storage tank 1.

[0054] The third step is to set the appropriate CAT / GOD enzyme acti...

Embodiment 3

[0062] First, according to figure 1 The device with a molecular weight cut-off of 5000Da is placed in the nanofiltration device 3, and the co-immobilized CAT / GOD cross-linked chitosan is filled in the co-immobilized glucose oxidase and catalase column reactor 7 Lysine resin, filled with anion exchange resin D239 in two chromatography columns 8.

[0063] In the second step, through the transfer pump 2a, the xylose crystallization mother liquor enters the nanofiltration device 3, and one end of the nanofiltration device outlet (nanofiltration decolorization solution) is connected to the bottom of the co-immobilized glucose oxidase and catalase column reactor 7 , to provide the xylose crystallization mother liquor that meets the requirements, and the intercepted liquid at the other end is connected to the main circulation pipeline and connected to the raw material liquid storage tank 1.

[0064] The third step is to set the appropriate CAT / GOD enzyme activity temperature in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com