Modified carbon nanometer coating used for scale inhibition of inner member of rectifying tower

A rectifying tower, carbon nanotechnology, applied in coating, metal material coating process, fractionation and other directions, to achieve good scale inhibition effect and small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

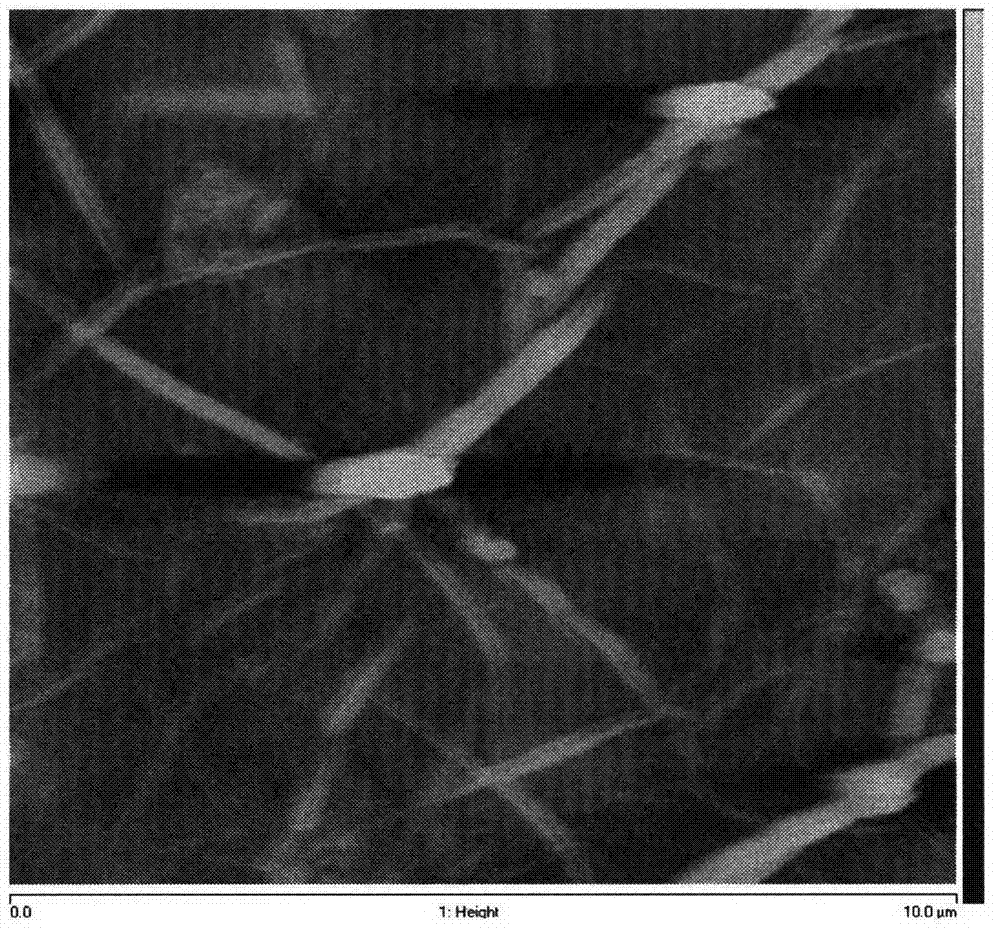

Image

Examples

Embodiment 1

[0021] For the water quality where the scaling substances are mainly calcium, the surface area is 3m 2 The rectification column tray is nano-coated, the specific process is as follows:

[0022] 1) Preparation of raw materials: Under the condition of ice-water bath, take bis-diphenylphosphinemethane and dimercaptomethane according to the mass ratio of 40:1 and mix them evenly, and store them in the ice-water bath;

[0023] 2) Preparation of modified carbon nanomaterials: take 0.3 g of the mixed solution obtained in step 1), inject it into an argon atmosphere tube furnace at a rate of 0.1 g / min using a metering pump, and heat it rapidly to 1000-1300 °C, at this time the raw material solution Complete gasification, keep the residence time of the gasification in the tube furnace for 3 minutes in this step;

[0024] 3) Chemical vapor phase in-situ deposition: place the tray in an argon atmosphere tube furnace, control the temperature at 1000°C, pass the vaporized product obtained ...

Embodiment 2

[0028] For the water quality where the scaling substance is mainly magnesium, the surface area is 100m 2 The rectification column packing is nano-coated,

[0029] The specific process is as follows:

[0030] 1) Preparation of raw materials: Under the condition of ice-water bath, take bis-diphenylphosphinemethane and dimercaptomethane according to the mass ratio of 1:10 and mix them evenly, and store them in the ice-water bath;

[0031] 2) Preparation of modified carbon nanomaterials: take 10 g of the mixed liquid obtained in step 1), inject it into an argon atmosphere tube furnace at a rate of 200 g / min using a metering pump, and heat it rapidly to 1000° C., at which point the raw material liquid is completely vaporized, Keep the residence time of the vaporized product in the tube furnace for 2 seconds in this step;

[0032] 3) Chemical vapor in-situ deposition: place the tray in an argon atmosphere tube furnace, control the temperature at 500°C, pass the gasified product ob...

Embodiment 3

[0036] For the water quality where the scaling substances are mainly calcium and magnesium and contain heavy metals, the surface area is 10m 2 The liquid distributor of the rectification tower is treated with nano-coating, the specific process is as follows:

[0037] 1) Preparation of raw materials: Under the condition of ice-water bath, take bis-diphenylphosphinemethane and dimercaptomethane according to the mass ratio of 1:1 and mix them evenly, and store them in the ice-water bath;

[0038] 2) Preparation of modified carbon nanomaterials: Take 1 g of the mixed liquid obtained in step 1), inject it into an argon atmosphere tube furnace at a rate of 10 g / min using a metering pump, and heat it rapidly to 1200 ° C, at this time the raw material liquid is completely vaporized, Keep the residence time of the vaporized product in the tube furnace for 30 seconds in this step;

[0039] 3) Chemical vapor in-situ deposition: place the tray in a hydrogen atmosphere tube furnace, contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com