Genetically engineered bacterium for converting cephalosporin C and preparation method thereof

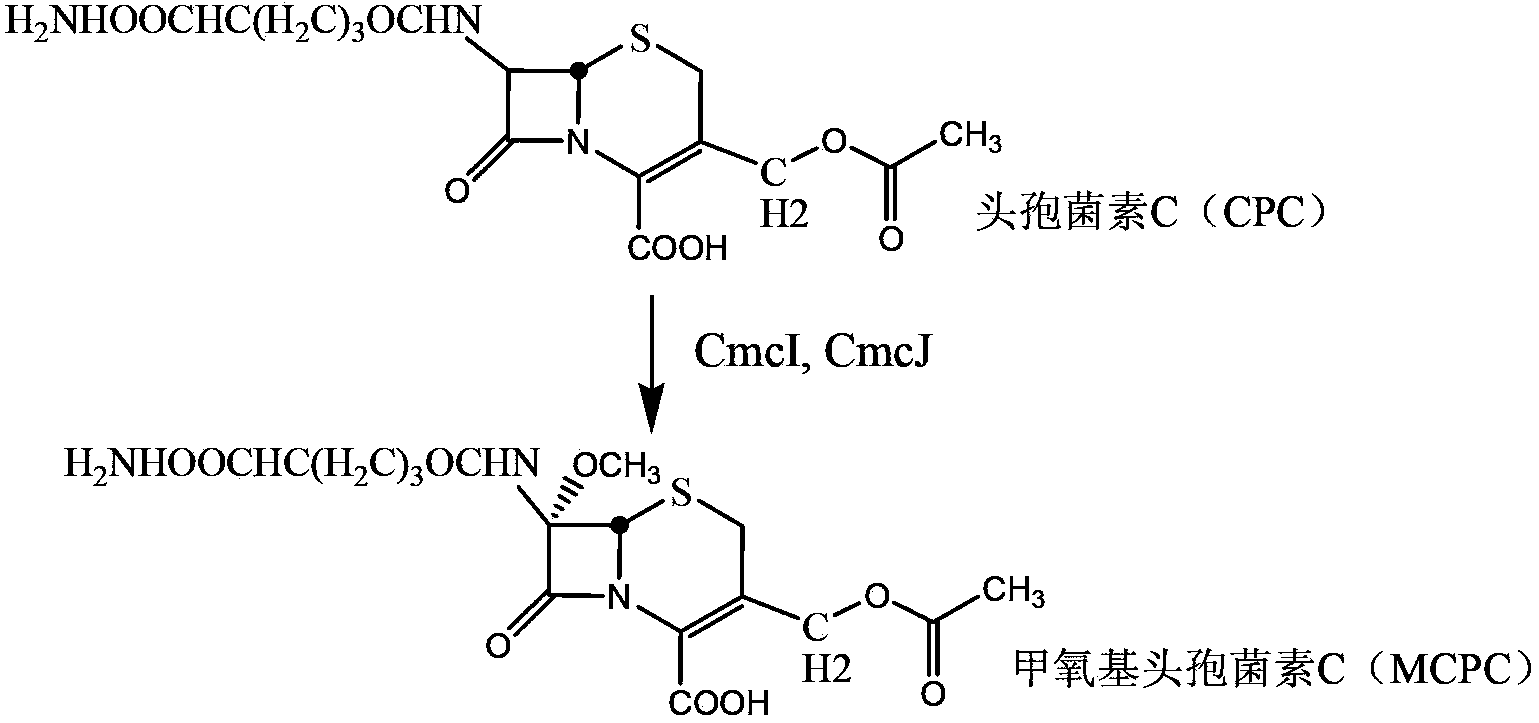

A technology of genetically engineered bacteria and cephalosporins, applied in genetic engineering, biochemical equipment and methods, botany equipment and methods, etc., can solve the problem of low transformation efficiency of strains, achieve stable transformation efficiency and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Cloning of erythromycin resistance gene promoter and cephalosporin C methylase gene coding sequence

[0035] First, the total genome of the erythromycin-producing strain S.erythraea HL 3168E3 (purchased from ATCC) was used as a template to clone the erythromycin resistance gene promoter, the upstream primer: 5'-AAAAGATCTTCTAGAAGCCCGACCCGAGCA-3'; the downstream primer: 5'- AAAGAATTCTCCGGAGGTCGCACC-3', PCR was performed, and the resulting PCR product was purified and ligated to plasmid pSP72 (purchased from Promega Company) to obtain plasmid pHJJ-9, which was sequenced, and the sequence showed 100% homology with online sequence alignment. The plasmid pHJJ-9 was directly digested to obtain the erythromycin resistance gene promoter (KpnI / SacI).

[0036] Primers were designed according to the cmcJ gene and its sequence in Streptomyces clavulatus in GenBank, upstream: 5'-AAAGAGCTCCAGTAGCCACCCCAGG-3'; downstream: 5'-TTTGGATCCTCGAAGCTGTCCTGGC-3'. Using the total gen...

Embodiment 2

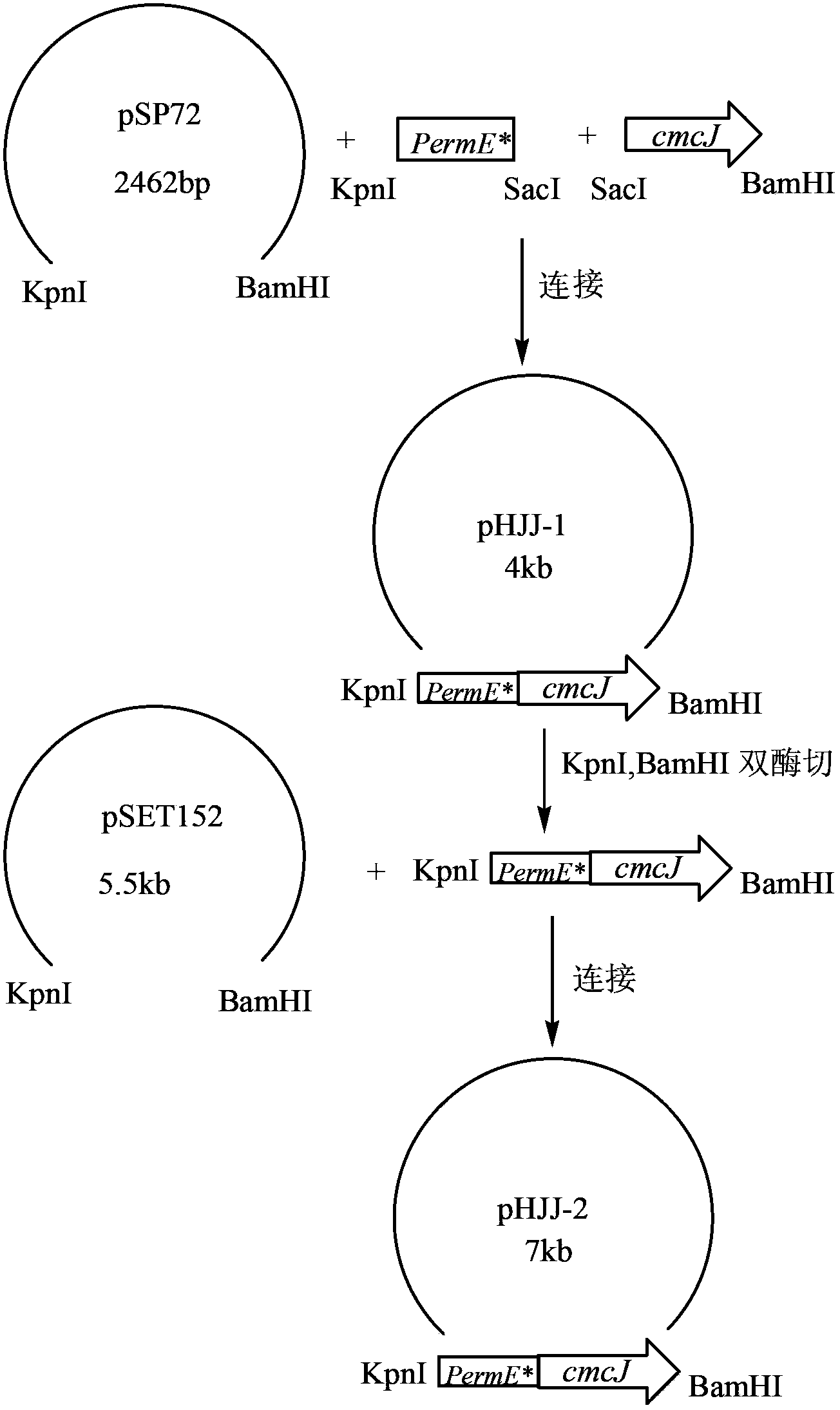

[0038] Example 2: Construction of specific site integration plasmid, conjugative transfer

[0039] The fragment (BamHI / EcoRI) containing the promoter of the erythromycin resistance gene and the coding sequence of the cmcJ gene was ligated into the plasmid pSET152 (BamHI / EcoRI) purchased from Takara Company to obtain the plasmid pHJJ-2. This recombinant plasmid is an integrated plasmid containing the erythromycin resistance gene promoter and the cmcJ gene coding sequence. This recombinant plasmid is used to transform large intestine DH5α, and the transformant is picked and cultured in LB. The plasmid is extracted for enzyme digestion and PCR (polymerase Chain reaction) verification, finally constructed into the specific site integration plasmid pHJJ-2. The schematic diagram of the above plasmid construction process is shown in figure 2 .

[0040] Incline culture Streptomyces clavuligerus ATCC27064. Pick an appropriate amount of bacteria from the slope and culture it in 50ml...

Embodiment 3

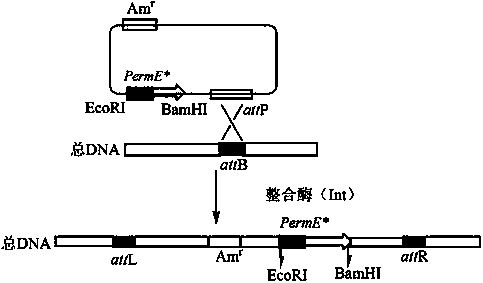

[0041] Example 3: Screening of Specific Site Homologous Recombination Engineering Bacteria

[0042] The zygotes were picked and cultured in TSB containing abramycin (50 μg / ml), and then the bacterial solution was applied to ISP2 medium containing abramycin (50 μg / ml), and cultured at 30°C. Because pSET152 contains phage The integration site (attP), which can be specifically homologously integrated with the attB site in the actinomycete genome, integrates the abramycin resistance gene carried by pHJJ-2 and the erythromycin resistance gene promoter and cmcJ gene The coding sequence is inserted into the attB site in the chromosome of Streptomyces clavulicularis and amplified synchronously with chromosome replication, and the zygote can stably express the abramycin resistance gene and the cmcJ gene. The zygote site-specific integration method, the schematic diagram is shown in image 3 . The zygotes were picked and placed in a 4ml TSB small test tube (50 μg / ml abramycin, 2-3 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com