Chickpea cheese-shaped moon cake and preparation method thereof

A technology of chickpeas and chickpea flour, applied in baking, baked goods, food science and other directions, can solve the problems of unreported and produced moon cakes, bad taste and fermented sour smell, etc., to overcome the taste and smell , Remove taste and odor, taste but not greasy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one: the preparation of chickpea cheese type moon cake

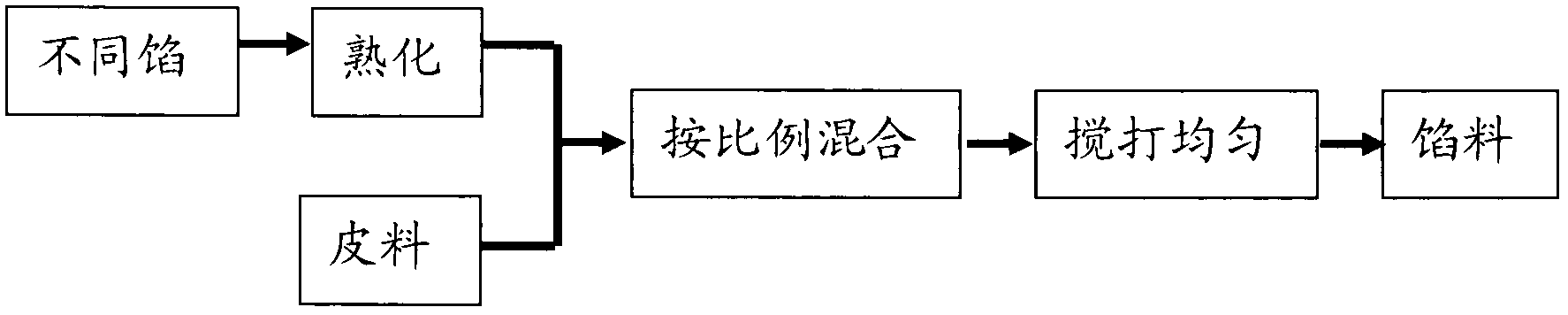

[0032] Chickpea cheese-shaped mooncakes are composed of skin, filling and cheese core. The main raw materials are chickpea flour, liquid milk and cheese, and glutinous rice flour, corn starch, pea starch, oil, etc. are used as auxiliary materials to prepare the skin. , cheese core and fillings, the moon cakes are obtained through the process of wrapping cheese cores with fillings, wrapping leather stuffing, loading molds, and pressing molds. Specifically, the moon cakes are obtained through the following preparation methods. The specific preparation method steps are as follows:

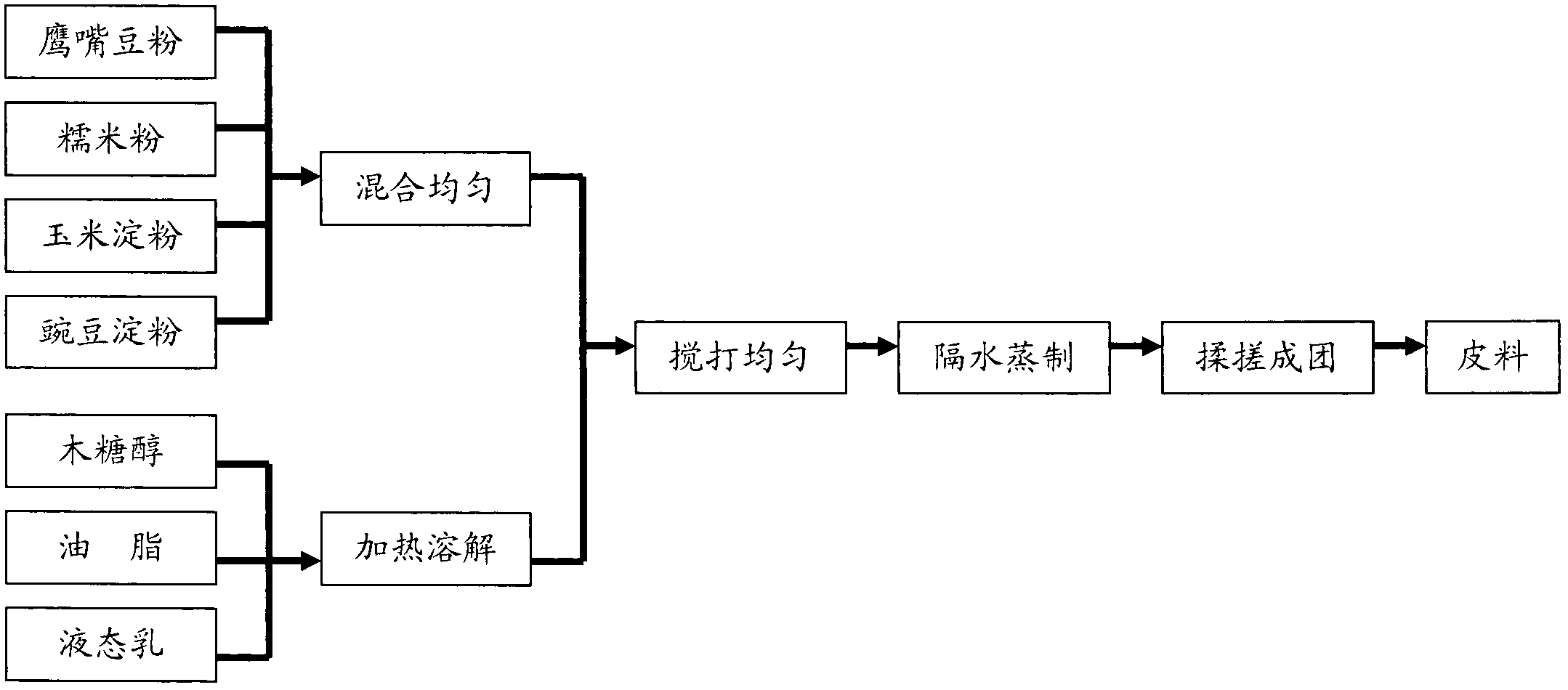

[0033] (1) The production steps of the skin material: respectively mix 40 parts of chickpea flour, 30 parts of glutinous rice flour, 20 parts of corn starch and 15 parts of pea starch solid phase materials, dissolve 20 parts of xylitol and 20 parts of corn oil Put it into 150 parts of milk at 35°C to prepare liquid phase materi...

Embodiment 2

[0037] Embodiment 2: the preparation of chickpea cheese type moon cake

[0038] (1) The production steps of the skin material: mix 60 parts of chickpea flour, 40 parts of glutinous rice flour, 20 parts of corn starch and 10 parts of pea starch solid phase materials, and dissolve 20 parts of xylitol and 20 parts of natural butter Put it into 180 parts of milk at 45°C to prepare the liquid phase material; then mix the solid phase and liquid phase materials evenly, steam for 24 minutes, stir and knead into a ball, cool to make leather material, the leather material occupies the moon cake 20% by weight.

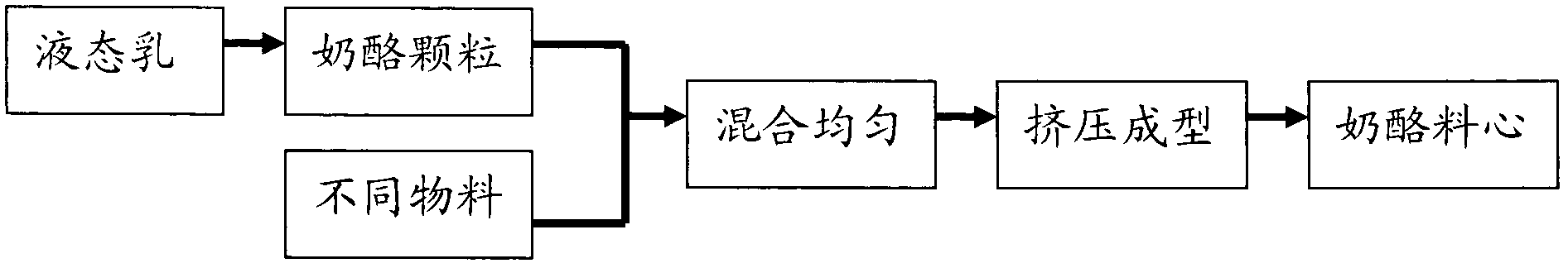

[0039] (2) The production steps of the cheese filling: the skim liquid milk is made into skim cheese granules according to the existing cheese granule processing technology, and the granules are extruded firmly without water precipitation; add peeled, dried and oiled almonds The wood kernel particles account for 8% of the weight of the cheese core, are uniformly mixed, and are m...

Embodiment 3

[0042] Embodiment 3: the preparation of chickpea cheese type moon cake

[0043] (1) The production steps of the skin material: respectively mix 70 parts of chickpea flour, 30 parts of glutinous rice flour, 15 parts of cornstarch and 15 parts of pea starch solid-phase materials, mix 20 parts of xylitol, 20 parts of sunflower oil Dissolved in 180 parts of milk at 40°C to prepare the liquid phase material; then the solid phase and liquid phase materials were mixed and whipped evenly, steamed in water for 26 minutes, stirred and kneaded into a ball, cooled to form a leather material, the leather material accounted for 20% of the weight of the mooncake.

[0044] (2) The production steps of the cheese core: make full-fat liquid milk into full-fat cheese granules according to the existing cheese granule processing technology, and squeeze the granules vigorously without water precipitation; add tribute chrysanthemum after washing and drying The petals, which account for 10% of the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com