High-performance hybrid separation membrane and preparation method thereof

A separation membrane, high-performance technology, applied in the field of separation membrane, can solve the problems of uneven dispersion and easy falling off of nanomaterials, and achieve the effect of simplifying the membrane modification process, strong universality, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0031] The preparation method of the nanocomposite polymer film of the present embodiment is carried out according to the following steps:

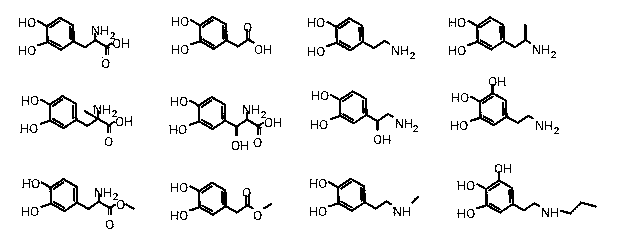

[0032] (1) Add 5 parts of polyethersulfone, 0.1 part of nano-titanium dioxide, 0.5 part of dopamine and 20 parts of N,N-dimethylformamide into the dissolution tank, and add them at different temperatures (25°C, 45°C, ℃, 65℃, 85℃), stirring and dissolving for 2 hours, standing for defoaming for 4 hours, and making a casting solution;

[0033] (2) Adjust the pH of the water and isopropanol coagulation bath to 8.0 by adding phosphate buffer;

[0034] (3) cast the casting solution on a flat plate to form a liquid film, and then soak it in a coagulation bath for 30 minutes to obtain a nanomaterial-doped polymer flat film;

[0035] (4) Soak the separation membrane prepared in step (3) in 15% Tween-20 aqueous solution for 50 minutes, and then dry it to assemble the membrane module.

Embodiment 5-9

[0037] The preparation method of the nanocomposite polymer film of the present embodiment is carried out according to the following steps:

[0038] (1) 20 parts by weight, 30 parts, 40 parts, 50 parts and 60 parts of polyethylene material, 3 parts of carbon nanotubes, 10 parts of 3,4-dihydroxybenzaldehyde and 80 parts by weight of Add ethanol into the dissolving tank, stir and dissolve for 12 hours under the condition of 100°C, and let it stand for defoaming for 8 hours to make a casting solution;

[0039] (2) Add 5 parts of hydrogen peroxide to the aqueous coagulation bath containing 3% N,N-dimethylformamide and N-methylpyrrolidone;

[0040] (3) The casting solution is spun on a hollow fiber membrane spinning machine, and then soaked in a coagulation bath for 12 hours to obtain a hollow fiber membrane;

[0041] (4) The separation membrane prepared in step (3) was soaked in 40% glycerol aqueous solution for 3 hours, and then dried to assemble the membrane module.

Embodiment 10-13

[0043] The preparation method of the nanocomposite polymer film of the present embodiment is carried out according to the following steps:

[0044] (1) Divide the weight into 10 parts of chitosan, 30 parts of different nanomaterials (montmorillonite, cumulated clay, silver nanoparticles, titanium nanorods), 1 part of 3,4-dihydroxyphenylacetic acid and Add 60 parts of pure water into the dissolution tank, stir and dissolve for 48 hours under the condition of 30°C, and let it stand for defoaming for 24 hours to make a casting solution;

[0045] (2) Add 2 parts of phenol to the pure water coagulation bath;

[0046] (3) The casting liquid is spun on a hollow fiber membrane spinning machine, and then soaked in a coagulation bath for 48 hours to obtain a hollow fiber membrane;

[0047] (4) Soak the separation membrane prepared in step (3) in 15% Tween-80 aqueous solution for 24 hours, and then dry it to assemble the membrane module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com