Preparation method of gallium oxide film with hole conduction characteristic as well as gallium oxide film with hole conduction characteristic

A technology of hole conduction and gallium oxide film, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of inability to prepare gallium oxide film with hole conduction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention discloses a method for preparing a hole-conducting gallium oxide film using metal organic chemical vapor deposition equipment. The method uses trimethylgallium or triethylgallium as the gallium source, and gaseous and / or liquid oxygen-containing substances as the The oxygen source is doped with a metal organic compound or a hydride or a nitride as a doping source, and then a gallium oxide film is prepared. Specifically, the method for preparing a gallium oxide film with hole-conducting properties of the present invention includes the following steps:

[0039] Step 1: Select the substrate and wash it for use. The cleaning adopts a standard cleaning process, which can clean the impurities on the surface of the substrate due to adsorption or reaction.

[0040] Step 2: Place the substrate on the growth tray in the sealed reaction chamber, and start the mechanical pump to evacuate the reaction chamber.

[0041] Step 3: When (the mechanical pump vacuumizes the r...

Embodiment 1

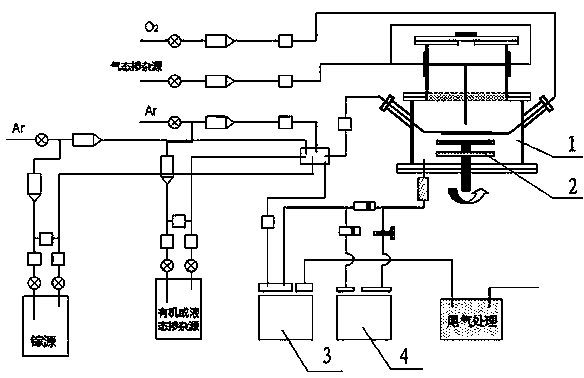

[0063] figure 1 It is a schematic diagram of the gas transport part of the metal organic chemical vapor deposition system used in the present invention.

[0064] The schematic diagram of the gas transport part of the metal organic chemical vapor deposition system used in this embodiment is as follows figure 1 As shown, the metal-organic chemical vapor deposition system includes a main reaction chamber 1 (the reaction chamber can achieve good sealing), and a rotatable tray 2 is arranged in the reaction chamber 1, and the tray 2 is used to place the substrate The reaction chamber 1 is connected to the mechanical pump 3 and the turbomolecular pump 4 through pipelines; in addition, the reaction chamber 1 is also provided with multiple pipelines connected to material supply devices (oxygen cylinders, argon cylinders, etc.).

[0065] Specifically, the preparation of the magnesium-doped gallium oxide film in this embodiment includes the following steps:

[0066] Step 1: Select the ...

Embodiment 2

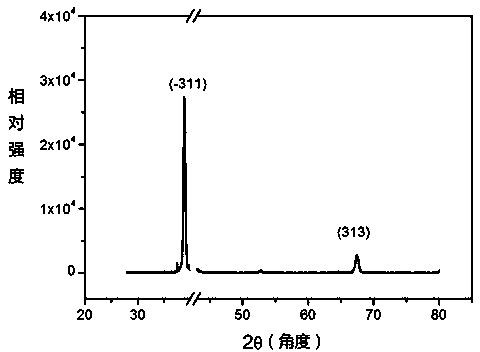

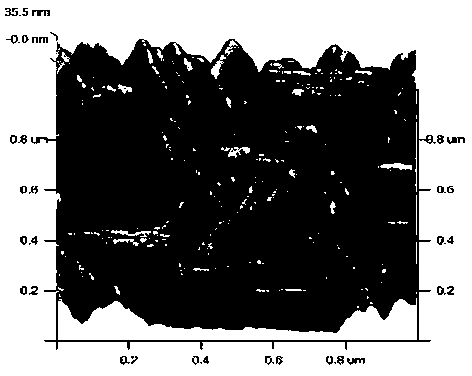

[0075] figure 2 For the X-ray diffraction pattern of the zinc-doped gallium oxide film prepared in embodiment 2; image 3 For the atomic force microscope collection of zinc-doped gallium oxide film prepared in embodiment 2; Figure 4 Transmission and absorption spectra of the zinc-doped gallium oxide film prepared for Example 2.

[0076] The gas transport part of the metal-organic chemical vapor deposition system used in this example is the same as that in Example 1. Specifically, the preparation of the zinc-doped gallium oxide film includes the following steps:

[0077] Step 1: Select the sapphire substrate and go through the standard cleaning process before use.

[0078] Step 2: Send the substrate into the reaction chamber 1 and place it on the growth tray 2, then close the transfer port of the reaction chamber 1 to seal the reaction chamber 1, and turn on the mechanical pump 3 to evacuate the gas in the reaction chamber 1.

[0079] Step 3: Start the turbomolecular pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com