Method for growing Ce: YAG monocrystal fluorescent material

A fluorescent material and single crystal technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of small segregation coefficient, difficult to increase Ce doping concentration, high dislocation density, etc., and achieve crystal internal defects less, simple growth method, large crystal size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

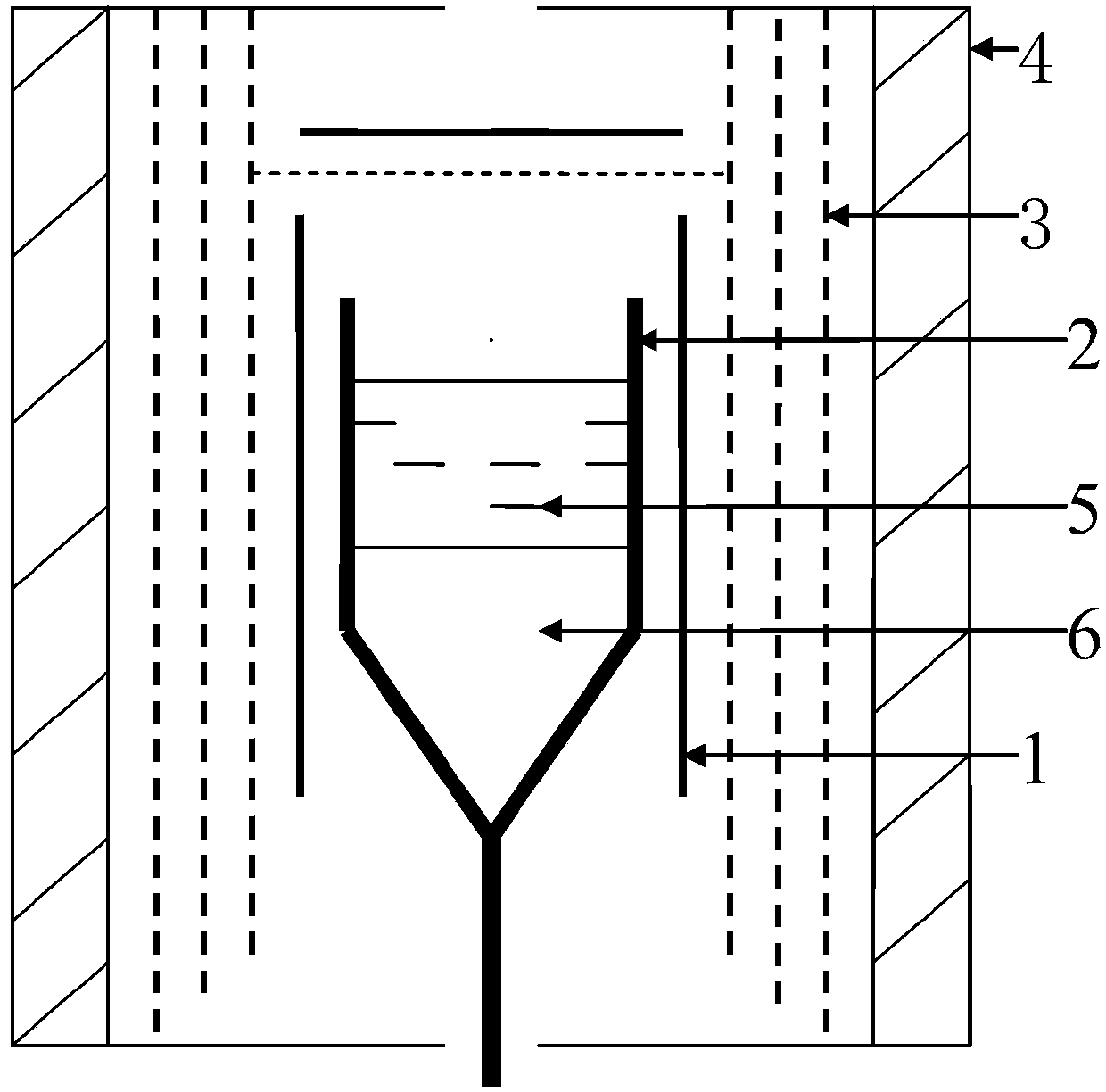

Method used

Image

Examples

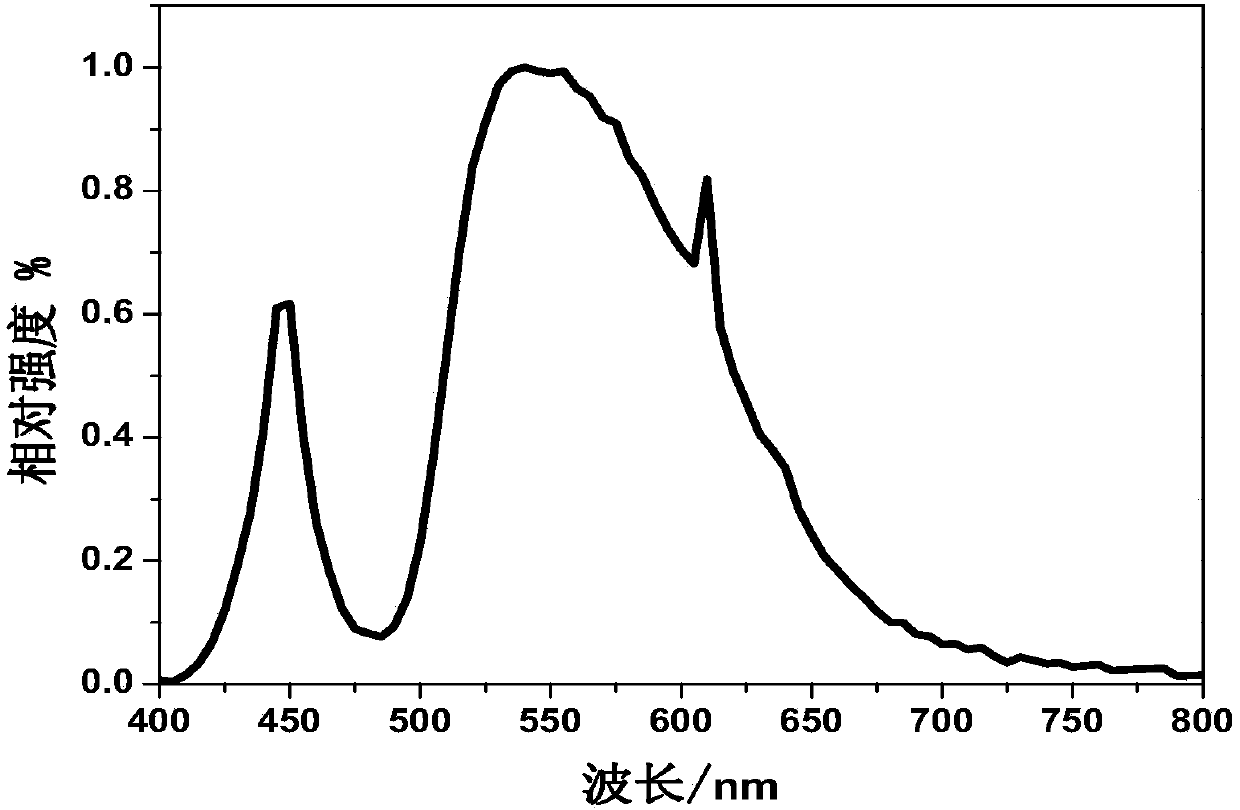

Embodiment 1

[0031] According to the chemical formula (Y 1-m Ce m ) 3 al 5 o 12 (m=0.01) raw material Y 2 o 3 、Al 2 o 3 , CeO 2 The molar ratio of the powder is weighed and proportioned, the total weight is 2.7Kg, mixed evenly, pressed into agglomerates, sintered at 1200°C for 12h; put into a crucible after sintering; the diameter of the crucible is 80mm, the length is 150mm; the orientation of the seed crystal is Put the crucible into the bottom of the crucible, put the crucible into the descending furnace, keep the furnace temperature at 1950°C, and keep the constant temperature for 5 hours; descend the crucible at a constant rate, the descending rate is 0.4mm / h, and the temperature gradient of the solid-liquid interface in the descending direction of the crucible is 25°C / cm; after the crystal growth is completed, control the furnace temperature to drop, the initial cooling rate is 1°C / h, and the cooling speed is accelerated from slow to fast, and the final cooling rate is 50°C / h,...

Embodiment 2

[0033] According to the chemical formula (Y 1-m Ce m ) 3 al 5 o 12 (m=0.008) raw material Y 2 o 3 、Al 2 o 3 , CeO 2 The molar ratio of the powder is weighed and proportioned, the total weight is 7.5Kg, mixed evenly, pressed into a block, sintered at 1200°C for 12h; put into a crucible after sintering; the diameter of the crucible is 120mm, the length is 220mm; the orientation of the seed crystal is Put the crucible into the bottom of the crucible, put the crucible into the descending furnace, keep the furnace temperature at 1950°C, and keep the constant temperature for 5 hours; descend the crucible at a constant rate, the descending rate is 0.2mm / h, and the temperature gradient of the solid-liquid interface in the descending direction of the crucible is 25°C / cm; control the temperature drop of the furnace, the initial cooling rate is 0.2°C / h, accelerate the cooling from slow to fast, and the final cooling rate is 30°C / h, and the cooling process is 180h; after the crysta...

Embodiment 3

[0035] According to the chemical formula (Y 0.99 Ce 0.01 ) 3 (Al 0.998 mn 0.002 ) 5 o 12 Weighing and proportioning, the total weight is 5Kg, mixed evenly, pressed into blocks, sintered at 1200°C for 12 hours; put into a crucible after sintering; the diameter of the crucible is 100mm, and the length is 200mm; put the seed crystal orientation into the bottom of the crucible , put the crucible into the descending furnace, keep the furnace temperature at 1950°C, and keep the constant temperature for 5 hours; descend the crucible at a constant rate, the descending rate is 0.3mm / h, and the temperature gradient of the solid-liquid interface in the descending direction of the crucible is 25°C / cm; Control the temperature drop of the furnace. The initial cooling rate is 0.5°C / h, and the cooling rate is accelerated from slow to fast. The final cooling rate is 35°C / h, and the cooling process is 120h. After the crystal growth is completed, the furnace body is naturally cooled to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com