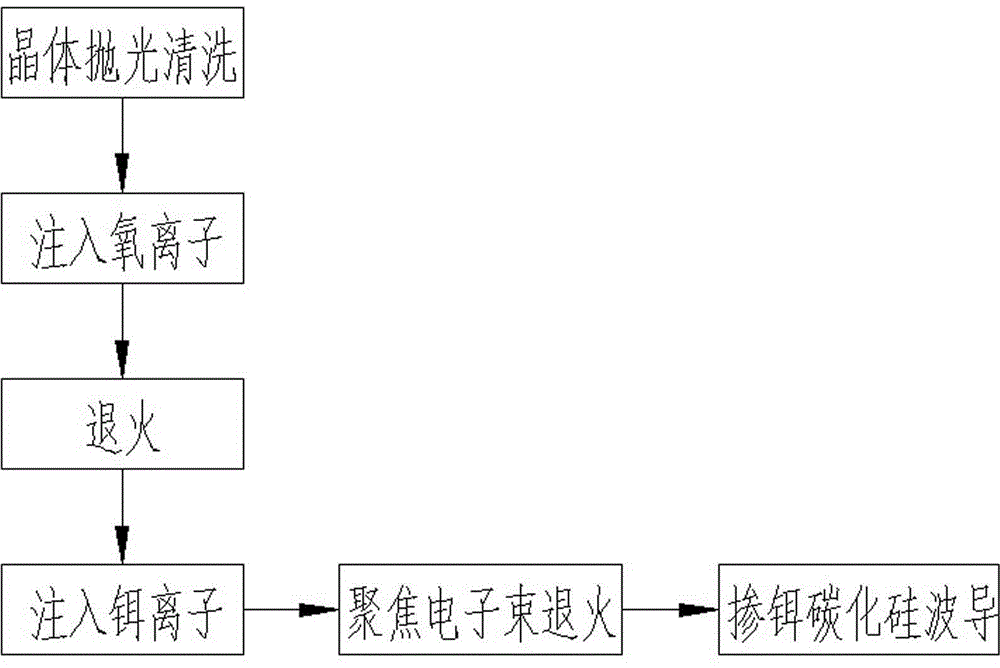

A method for preparing erbium-doped silicon carbide optical waveguide by ion implantation

A silicon carbide optical and ion implantation technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of secondary defects, low activation efficiency, restricting erbium-doped silicon carbide optical waveguides, etc., to improve optical gain and enhance fluorescence. Luminous efficiency, avoiding the effect of low waveguide gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The silicon carbide sample 1 that has been cut and optically polished is cleaned with acetone and ultrasonic waves, and then the cleaned silicon carbide sample 1 is cleaned.

[0029] (2) Put the sample cleaned in (1) in the target chamber of the accelerator, and evacuate to 1×10 Pa, the implantation process of oxygen ions is performed. The injection energy is 0.5MeV, and the injection dose is 1×10 ions / cm , the whole process is carried out at a temperature of 600°C.

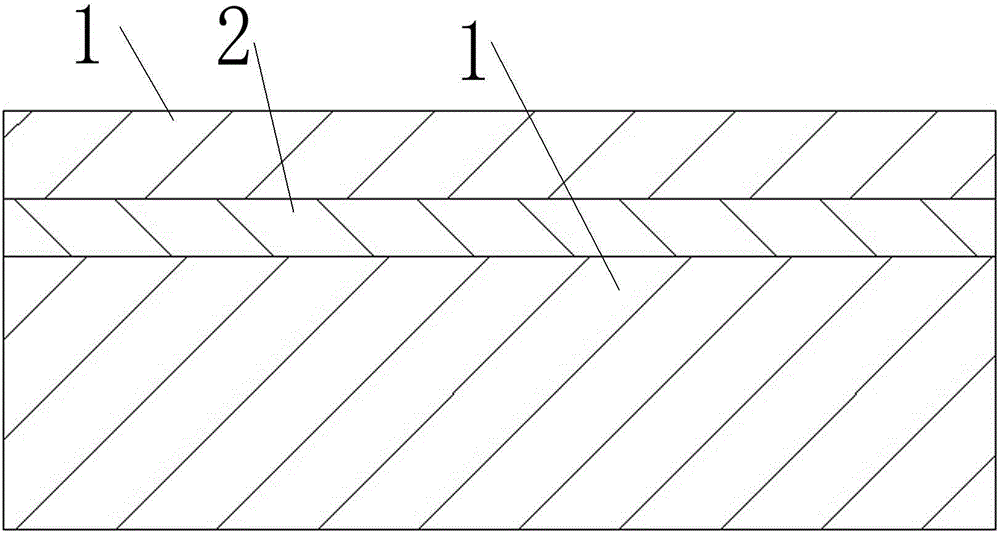

[0030] (3) Place the sample obtained in (2) in an annealing furnace, and perform high-temperature annealing treatment on the sample in an argon atmosphere. The annealing temperature is controlled at 1200°C, and the annealing time is 0.5h. Through this process, a silicon dioxide buried layer 2 with a thickness of approximately 600 nm and a near-stoichiometric ratio can be obtained on the silicon carbide sample.

[0031] (4) Place the sample obtained in (3) in the target chamber of the accelerato...

Embodiment 2

[0035] (1) The silicon carbide sample 1 that has been cut and optically polished is cleaned with acetone and ultrasonic waves, and then the cleaned silicon carbide sample 1 is cleaned.

[0036] (2) Put the sample cleaned in (1) in the target chamber of the accelerator, and evacuate to 1×10 Pa, the implantation process of oxygen ions is performed. The injection energy is 1MeV, and the injection dose is 2.5×10 ions / cm , the whole process is carried out at a temperature of 650°C.

[0037] (3) Place the sample obtained in (2) in an annealing furnace, and perform high-temperature annealing treatment on the sample in an argon atmosphere. The annealing temperature is controlled at 1200° C., and the annealing time is 1 h. A nearly stoichiometric silicon dioxide buried layer 2 with a thickness of about 970 nm can be obtained on the silicon carbide sample through this process.

[0038] (4) Place the sample obtained in (3) in the target chamber of the accelerator, and evacuate to...

Embodiment 3

[0042] (1) The silicon carbide sample 1 that has been cut and optically polished is cleaned with acetone and ultrasonic waves, and then the cleaned silicon carbide sample 1 is cleaned.

[0043] (2) Put the sample cleaned in (1) in the target chamber of the accelerator, and evacuate to 1×10 Pa, the implantation process of oxygen ions is performed. The injection energy is 2.0MeV, and the injection dose is 2.5×10 ions / cm , the whole process is carried out at a temperature of 650°C.

[0044] (3) Place the sample obtained in (2) in an annealing furnace, and perform high-temperature annealing treatment on the sample in an argon atmosphere. The annealing temperature is controlled at 1200° C., and the annealing time is 1 h. Through this process, a silicon dioxide buried layer 2 with a thickness of approximately 600 nm and a near-stoichiometric ratio can be obtained on the silicon carbide sample.

[0045] (4) Place the sample obtained in (3) in the target chamber of the acceler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com