Hollow internal-pressing fiber film and preparation method thereof

A fiber and internal pressure technology, which is applied in the field of hollow fiber internal pressure membrane and its preparation, can solve the problems of limited maintenance and cleaning methods, inapplicability of hollow fiber membrane, and small pore size of hollow fiber membrane, so as to reduce deep pollution and improve affinity Water-based, viscosity-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

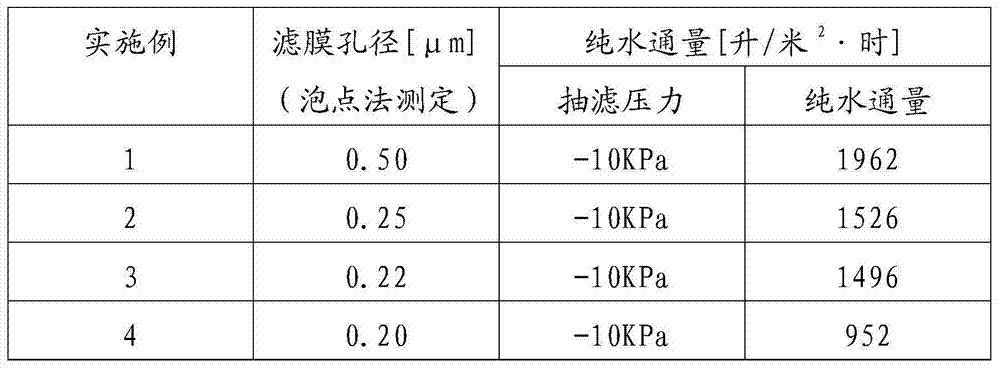

Embodiment 1

[0026] By weight percentage, 5% polyethersulfone resin, 5% molecular weight is 10 6 Add Dalton's polyacrylonitrile resin, 3% lithium chloride, 3% polyvinylpyrrolidone and 5% ethylene glycol to 79% dimethylacetamide (DMAc), stir and dissolve at 80°C , mix evenly, and remove the air bubbles to obtain the casting solution.

[0027] The above casting solution is extruded through the spinneret and enters the coagulation bath. After gelling for a certain period of time, the as-spun polyethersulfone hollow fiber with a through-hole structure and uniform large-diameter internal pressure film is obtained. Among them, the outer coagulation bath is a dimethylacetamide (DMAc) aqueous solution with a water concentration of 70% at 50°C, and the inner coagulation bath is pure water.

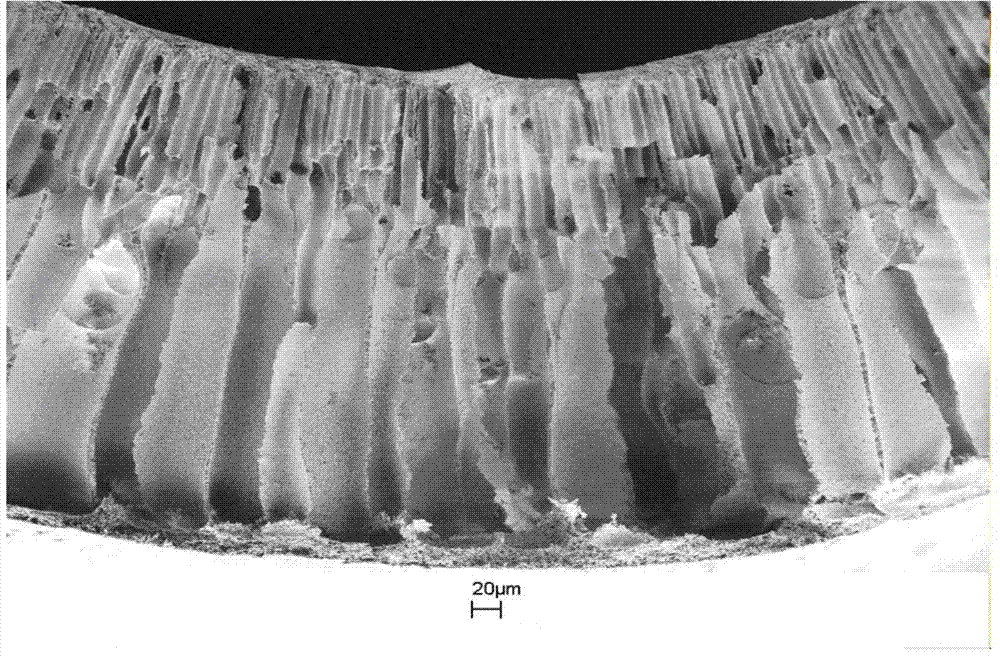

[0028] figure 1 It is the topography diagram of the cross-section of the obtained hollow fiber membrane. In the figure, the magnification = 170X, the field of view width = 7mm, the test voltage = 2.00KV, the...

Embodiment 2

[0030] By weight percentage, with 8% polyethersulfone resin, 3% molecular weight is 10 5 Dalton's polyacrylonitrile resin, 5% calcium chloride, 1% polyoxyethylene and 3% ethylene glycol were added to 80% dimethyl sulfoxide (DMSO), stirred and dissolved at 50°C, After mixing evenly and removing air bubbles, the casting solution is obtained.

[0031] The above-mentioned casting solution is extruded through the spinneret and enters the coagulation bath. After gelling for a certain period of time, the as-spun polyethersulfone hollow fiber with a through-hole structure and uniform large-aperture internal pressure film is obtained. The outer coagulation bath is 30°C , The concentration of water is 80% dimethylformamide (DMF) aqueous solution, and the inner coagulation bath is pure water.

Embodiment 3

[0033] By weight percentage, with 12% polyethersulfone resin, 1% molecular weight is 10 5 Polyacrylonitrile, 1% lithium nitrate, 2% polyvinylpyrrolidone mixed with 1% polyvinyl alcohol and 5% diethylene glycol were added to 78% dimethylformamide (DMF), in Stir and dissolve at 60°C, mix evenly, and remove air bubbles to obtain a casting solution.

[0034] The above-mentioned casting solution is extruded through the spinneret and enters the coagulation bath. After gelling for a certain period of time, the as-spun polyethersulfone hollow fiber with a through-hole structure and uniform large-aperture internal pressure film is obtained. The outer coagulation bath is 70°C , The concentration of water is 90% N-methylpyrrolidone (NMP) aqueous solution, and the internal coagulation bath is pure water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com