Preparation method of dual functional chitosan microspheres

A technology of chitosan microspheres and dual functions, which is applied in the field of preparation of chitosan microspheres, can solve problems such as the difficulty in preparing monodisperse cross-linked particles, and achieve environmental protection and economy of experimental materials, convenient operation process, and adjustable size. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

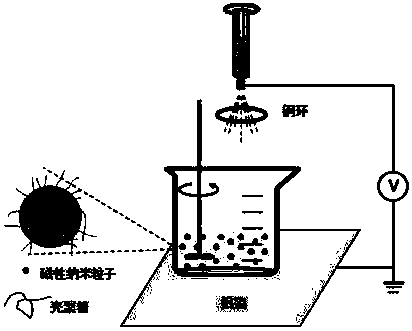

[0038] 1. Superparamagnetic Fe 3 O 4 Preparation of nanoparticles

[0039] Weigh 2.705g (0.01mol) FeCl 3 ·6H 2 O and 0.995g (0.005mol) FeCl 2 ·4H 2 O was dissolved in 100ml of deionized water, transferred to a 250ml three-neck flask, vigorously stirred under nitrogen protection and gradually heated to 80°C, after 5 minutes of constant temperature, 5ml of concentrated ammonia water (25wt%) was slowly added dropwise with a constant pressure burette, After 2 minutes of titration, measure the pH value of the solution, adjust the pH value to 8-9, and continue the constant temperature reaction for 20 minutes under the protection of nitrogen. After the reaction, the product was magnetically separated, washed with water for 3 times until the solution was neutral, and washed with ethanol for 2 times to obtain superparamagnetic Fe 3 O 4 Nanoparticles 1g. The prepared superparamagnetic Fe 3 O 4 Nanoparticles were dispersed in 100 mL ethanol solution to obtain superparamagnetic ...

Embodiment 2

[0045] 1. Superparamagnetic Fe 3 O 4 Preparation of nanoparticles

[0046] Weigh 2.705g (0.01mol) FeCl 3 ·6H 2 O and 0.995g (0.005mol) FeCl 2 ·4H 2 O was dissolved in 100ml of deionized water, transferred to a 250ml three-neck flask, vigorously stirred under nitrogen protection and gradually heated to 80°C, after 5 minutes of constant temperature, 5ml of concentrated ammonia water (25wt%) was slowly added dropwise with a constant pressure burette, After 2 minutes of titration, measure the pH value of the solution, adjust the pH value to 8-9, and continue the constant temperature reaction for 20 minutes under the protection of nitrogen. After the reaction, the product was magnetically separated, washed with water for 3 times until the solution was neutral, and washed with ethanol for 2 times to obtain superparamagnetic Fe 3 O 4 Nanoparticles 1g. The prepared superparamagnetic Fe 3 O 4 Nanoparticles were dispersed in 100 mL ethanol solution to obtain superparamagnetic ...

Embodiment 3

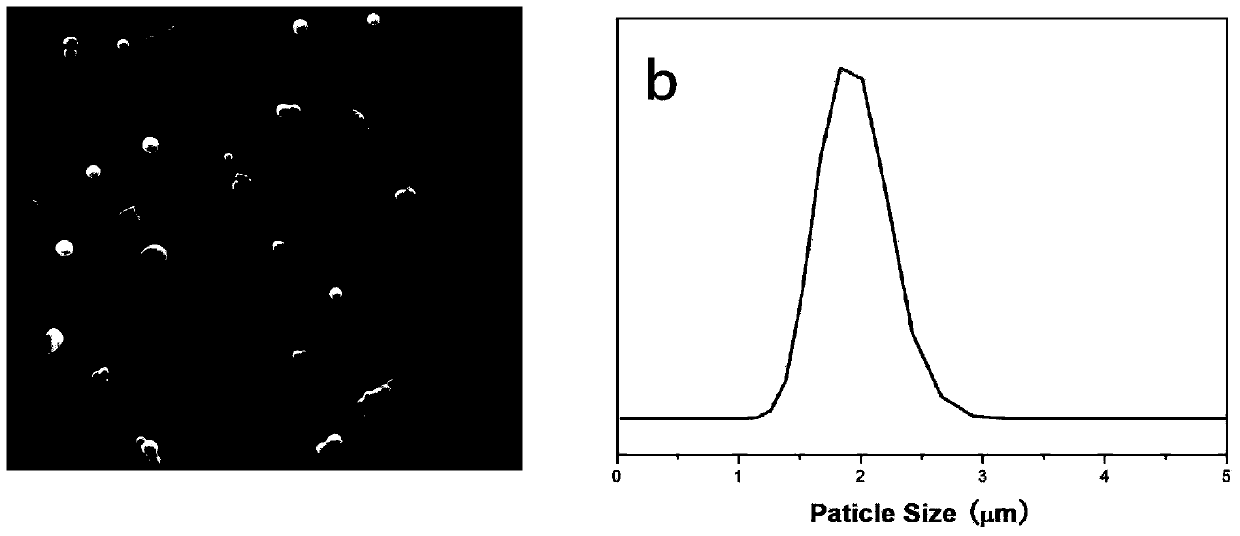

[0052] The preparation process of this example is the same as that of Example 1, the difference is that the needle type used in step 2) is 8# and the voltage is 30kv. The particle size of the bifunctional chitosan microspheres prepared in this example is about 1.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com