Method for recycling mercury from mercurial soot or mercurial salt in environment-friendly mode

A technology of mercury salt and mercury soot, which is applied in the field of mercury recovery, can solve the problems of secondary pollution by distillation, achieve remarkable environmental and social benefits, clean process, and good labor hygiene conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

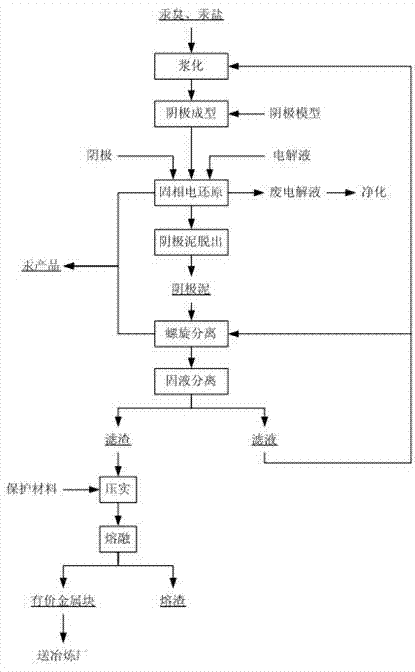

Method used

Image

Examples

Embodiment 1

[0030] Element content(%) Hg 23.13 HgS 3.89 HgSO 4 0.007 Sb 总 0.31 Sb 2 o 3 0.07 As 2 o 3 0.45 SiO 2 5.3 Al 2 o 3 4.15 CaO 1.55

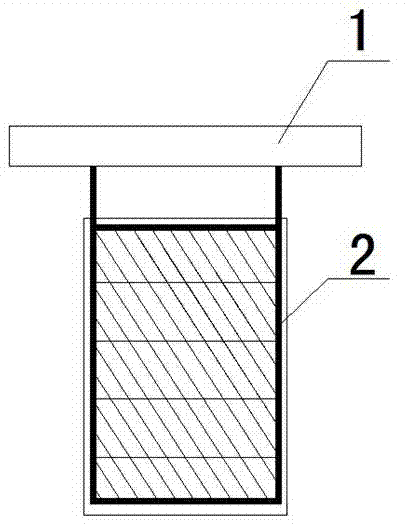

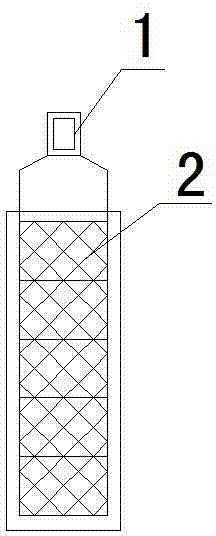

[0031] (1) Make the electrolysis cathode before electrolysis, specifically (see Figure 2-3 ) The lower part of the conductive rod 1 is welded with the cathode plate mold 2. The inner core of the conductive rod is copper core, and the outer part is casted by lead-antimony alloy. The cathode plate mold is surrounded by a steel mesh into a flat box shape, and the mesh is square, rectangular or diamond-shaped, etc. Geometry, mesh area 250-10000 mm 2 ; Mix 98% of mercury soot or mercury salt with 2% of graphite powder, add water to make a paste, fill it into the cathode plate mold and compact it, and the filling method is manually or using an automatic cathode plate forming machine. The thickness of the cathode plate is 30-40 mm. Put the cathode plate into an alkali-resis...

Embodiment 2

[0036] Compared with Embodiment 1, the difference is:

[0037] The main material accounts for 97.5%, fly ash accounts for 2%, graphite powder accounts for 0.5%;

[0038] After step (3) there is also

[0039] (4) Slurry separation. After one cycle of electrolysis, the cathode plate is lifted out of the electrolytic cell, and the cathode slime is extracted from the cathode extraction system; the extracted cathode slime enters the spiral separator to further separate metallic mercury; the said cycle is 36 hours~ 42 hours;

[0040] (5) Solid-liquid separation, the separated cathode mud enters the filter press with a mud pump for solid-liquid separation, and the filtrate returns to the step (1) slurrying process; the separated filter residue is compacted and enters the furnace to melt valuable metals ;

[0041] (6) Purify the electrolyte, use the solubility difference of sodium polysulfide to temperature, cool and crystallize sodium polysulfide, and use sodium polysulfide as...

Embodiment approach 3

[0043] Compared with Embodiment 1, the difference is:

[0044] The main material accounts for 97%, fly ash accounts for 2.4%, and graphite powder accounts for 0.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com