Preparation method of acrylonitrile-butadiene-styrene (ABS) resin multi-component nano functional drying agent

A technology of styrene resin and butadiene, which is applied in the field of preparation of nano-environmental-friendly functional materials, can solve the problems of neglecting the negative effects of drying masterbatch, and achieve the effects of eliminating drying process, excellent aging resistance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

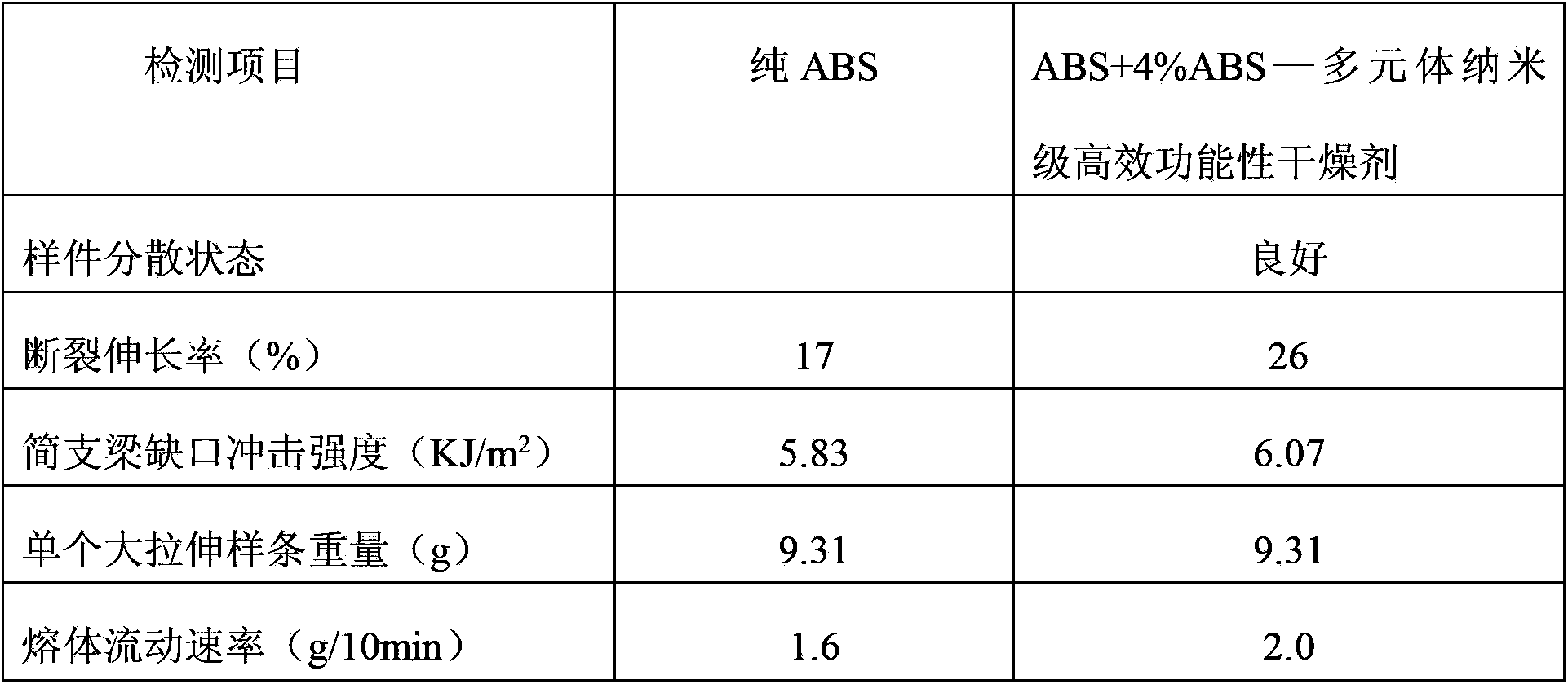

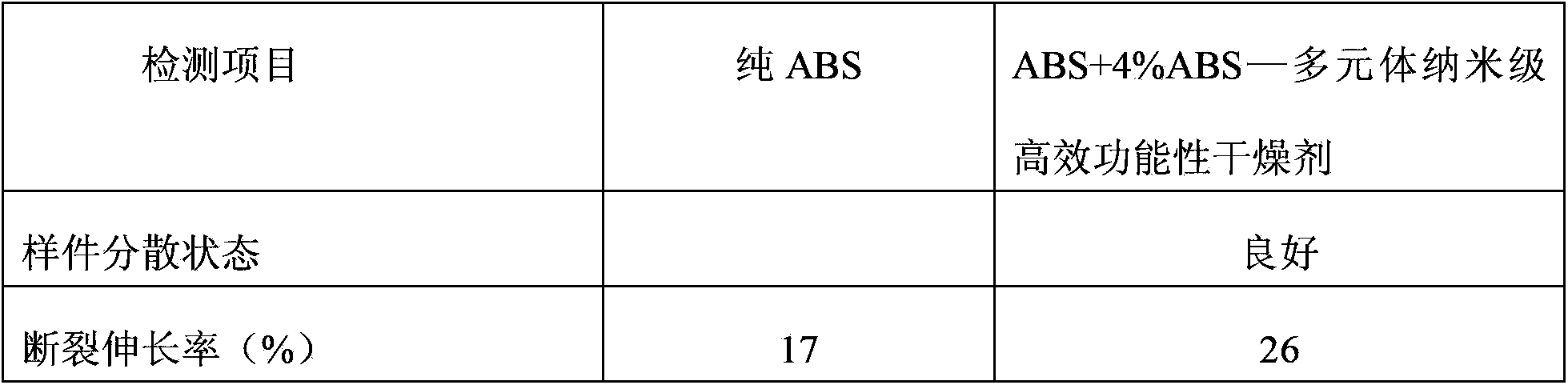

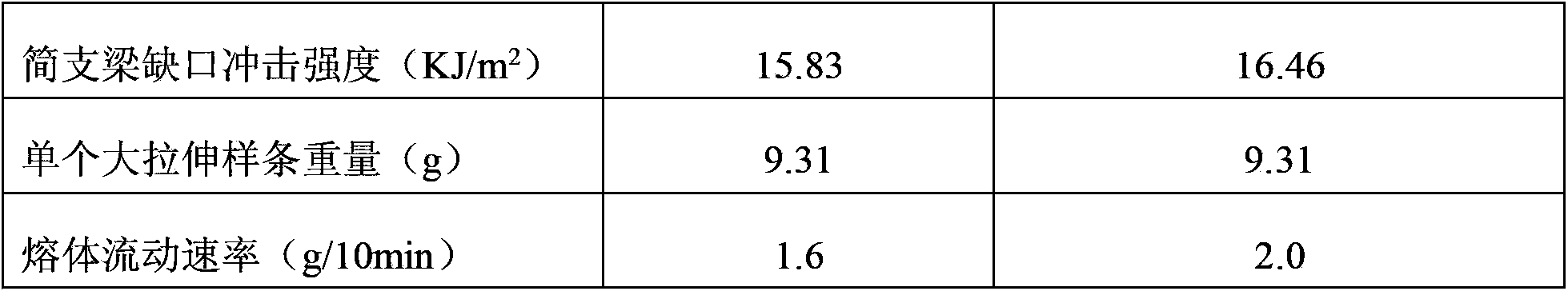

Examples

example 1

[0021] Example 1, the specific material components for preparing the desiccant are respectively by weight percentage:

[0022] Nano Calcium Carbonate 66% ABS 19% Calcium Oxide 8%

[0023] Aluminum-titanium composite coupling agent 1.6%

[0024] Fatty acid polyol ester antistatic agent 0.4%

[0025] SBS (styrene-butadiene-styrene block copolymer) toughening agent 2%

[0026] Zinc stearate lubricant 0.65%

[0027] Tetrabromobisphenol A flame retardant 0.25%

[0028] Brightener 1,4-bis(o-cyano-styryl)benzene 0.06%

[0029] Antioxidant 4,4'-thiobis-(6-tert-butyl-3-methylphenol) 0.04%

[0030] DOP (dioctyl phthalate) plasticizer 2%

Embodiment 2

[0031] Embodiment two, the specific material components of preparing the desiccant are respectively by weight percentage:

[0032] Nano Calcium Carbonate 75% ABS 14% Calcium Oxide 4%

[0033] Aluminum-titanium composite coupling agent 1.8%

[0034] Fatty acid polyol ester antistatic agent 0.5%

[0035] SBS (styrene-butadiene-styrene block copolymer) toughening agent 2.3%

[0036] Zinc stearate lubricant 0.6%

[0037] Tetrabromobisphenol A flame retardant 0.2%

[0038] Brightener 1,4-bis(o-cyano-styryl)benzene 0.07%

[0039] Antioxidant 4,4'-thiobis-(6-tert-butyl-3-methylphenol) 0.03

[0040] DOP (dioctyl phthalate) plasticizer 1.5

Embodiment 3

[0041] Embodiment three, the concrete material component of preparing this desiccant is respectively by weight percentage:

[0042] Nano Calcium Carbonate 84% ABS 6% Calcium Oxide 3%

[0043] Aluminum-titanium composite coupling agent 2.2%

[0044] Fatty acid polyol ester antistatic agent 0.6%

[0045] SBS (styrene-butadiene-styrene block copolymer) toughening agent 2.5%

[0046] Zinc stearate lubricant 0.5%

[0047] Tetrabromobisphenol A flame retardant 0.1%

[0048] Brightener 1,4-bis(o-cyano-styryl)benzene 0.08%

[0049] Antioxidant 4,4'-thiobis-(6-tert-butyl-3-methylphenol) 0.02%

[0050] DOP (dioctyl phthalate) plasticizer 1

[0051] Specific implementation steps:

[0052] Step 1. Weigh 65% to 85% of nano calcium carbonate by weight, put it into the mixer, start low-speed operation, and mix at a speed of 300 to 500 revolutions per minute;

[0053]Step 2. Weigh 0.3% to 0.6% fatty acid polyol ester antistatic agent by weight, put it into the mixer, run it at a low s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com