Method for producing ethanol and biogas and co-producing electricity by using corn straws

A technology of corn stalks and ethanol, which is applied in fermentation, biofuels, machines/engines, etc., can solve problems such as difficult large-scale production, failure to adopt, and environmental pollution, so as to improve comprehensive utilization rate, increase energy utilization rate, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

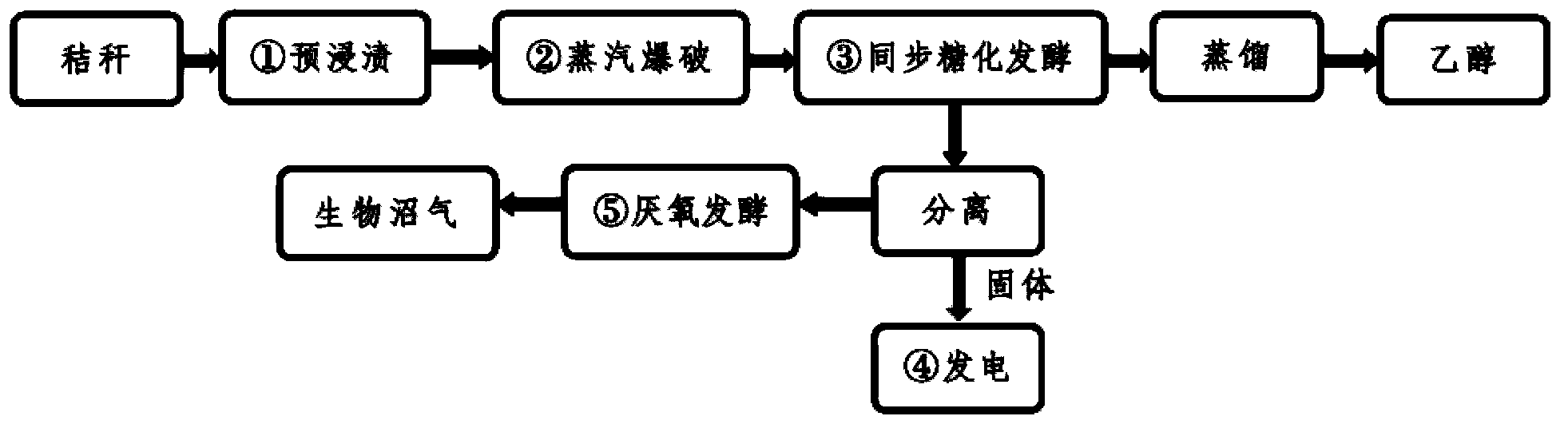

[0078] Such as figure 2 As shown in the flow chart shown, the corn stalks are processed by the following method to produce ethanol and biogas and co-generate electricity at the same time.

[0079] ① Pre-impregnation: Firstly, take corn stalks, grind them to 1-5 cm with a hammer mill, and then use 0.2% sulfuric acid to pre-impregnate corn stalks at room temperature and pressure for 120 minutes.

[0080] ②Steam explosion treatment: place the pre-impregnated straw in a steam explosion reactor at a temperature of 190°C (pressure 1.25MPa) for 10 minutes, then open the valve instantly (less than 0.5 seconds) to remove the pre-treated straw. The straw pulp is flushed into the flash tank.

[0081] ③ Simultaneous saccharification, fermentation and distillation: the straw pulp in the flash tank is placed in the fermentation tank so that the solid-liquid mass percentage in the fermentation system is 10%, and the fermentation system also contains 0.5g / l diammonium hydrogen phosphate and...

Embodiment 2

[0092] Such as figure 2 As shown in the flow chart shown, the corn stalks are processed by the following method to produce ethanol and biogas and co-generate electricity at the same time.

[0093] ① Pre-impregnation: Firstly, take corn stalks, grind them to 1-5 cm with a hammer mill, and then use 1% acetic acid to pre-impregnate corn stalks at room temperature and pressure for 120 minutes.

[0094] ②Steam explosion treatment: place the pre-impregnated straw in a steam explosion reactor at a temperature of 200°C (pressure 1.55MPa) for 5 minutes, then open the valve instantly (less than 0.5 seconds), and the pretreated straw The straw pulp is flushed into the flash tank.

[0095] ③ Synchronous saccharification and fermentation and distillation, ④ solid residue combustion to generate electricity, ⑤ anaerobic fermentation steps are the same as in Example 1.

[0096] Relevant technical indicators are as follows:

[0097] The recoveries of glucose and xylose after dilute acetic ac...

Embodiment 3

[0104] Such as figure 2 As shown in the flow chart shown, the corn stalks are processed by the following method to produce ethanol and biogas and co-generate electricity at the same time.

[0105] ① Pre-impregnation: Firstly, take corn stalks, grind them to 1-5 cm with a hammer mill, and then use 1% acetic acid to pre-impregnate corn stalks at room temperature and pressure for 120 minutes.

[0106] ②Steam explosion treatment: place the pre-impregnated straw in a steam explosion reactor at a temperature of 200°C (pressure 1.55MPa) for 5 minutes, then open the valve instantly (less than 0.5 seconds), and the pretreated straw The straw pulp is flushed into the flash tank.

[0107] ③ Simultaneous saccharification, fermentation and distillation: the straw pulp in the flash tank is placed in the fermentation tank so that the solid-liquid mass percentage in the fermentation system is 10%, and the fermentation system also contains 0.5g / l diammonium hydrogen phosphate and diammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com