Galangin molecular imprinting polymer, and preparation method and application thereof

A technology of galangin and molecular imprinting, applied in chemical instruments and methods, other chemical processes, organic chemistry, etc., can solve the problems of high cost, low recovery rate, poor separation efficiency, etc., achieve high selectivity, improve purity and Recovery, effect of reducing separation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

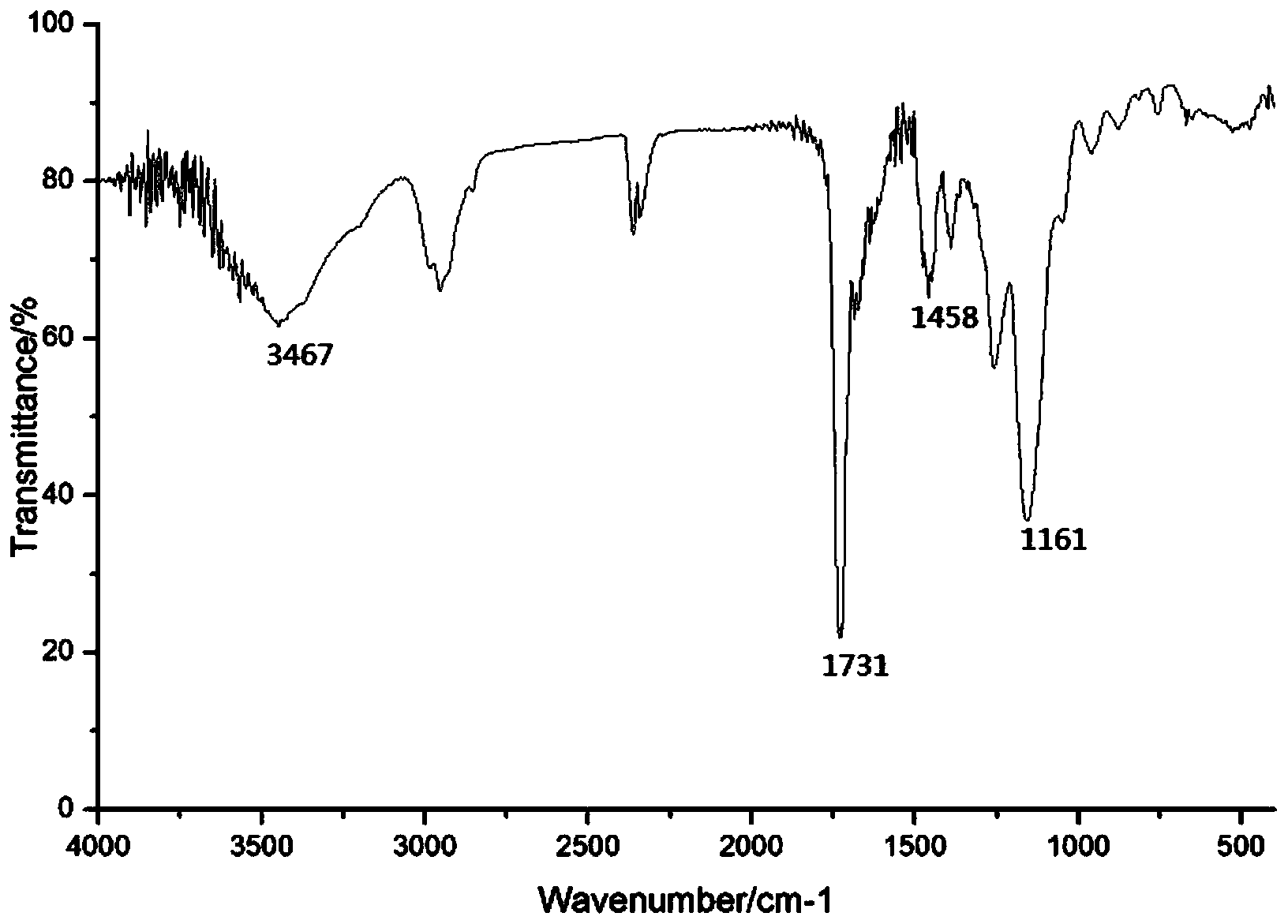

[0027] (1) Weigh 0.27g (1mmol) of galangin and 0.28g (4mmol) of functional monomer acrylamide and dissolve them in 4mL of acetone, and ultrasonicate for 120min in a 10mL colorimetric tube to fully generate template molecules and functional monomers function, then add 3.8mL (20mmol) crosslinking agent ethylene glycol dimethacrylate and 0.033g (0.2mmol) initiator azobisisobutyronitrile, ultrasonic 15min, after fully miscible, pass N 2 Deoxidize for 10 minutes, seal immediately, and polymerize in a water bath at 60°C for 24 hours to obtain a rod-shaped polymer;

[0028] (2) Grind and sieve the rod-shaped polymer obtained in step (1), take a polymer of 200-400 meshes, and repeatedly extract it with a methanol solution with a volume ratio of 10% acetic acid in a Soxhlet extractor, each time for 24 hours, To remove template molecules and unreacted compounds, and then wash with methanol repeatedly, each time for 5h, to remove residual acetic acid to neutral until the eluate is detect...

Embodiment 2

[0031] (1) Weigh 0.27g (1mmol) of galangin and 0.43g (6mmol) of functional monomer acrylamide and dissolve them in 5mL of acetone, and ultrasonicate for 120min in a 10mL colorimetric tube to fully generate template molecules and functional monomers effect, then add 3.8mL (20mmol) crosslinking agent ethylene glycol dimethacrylate and 0.041g (0.25mmol) initiator azobisisobutyronitrile, ultrasonic 15min, after fully miscible, pass N 2 Deoxidize for 15 minutes, seal immediately, and polymerize in a water bath at 65°C for 20 hours to obtain a rod-shaped polymer;

[0032] (2) Grind and sieve the obtained rod-shaped polymer, take 200-400 mesh polymer, and use a methanol solution with a volume ratio of 10% acetic acid to extract repeatedly in a Soxhlet extractor for 24 hours each time to remove template molecules and unreacted compounds, and then washed repeatedly with methanol for 5 hours each time to remove residual acetic acid to neutral until the eluate was detected by ultraviolet...

Embodiment 3

[0034] (1) Weigh 0.27g (1mmol) of galangin and 0.22g (3mmol) of functional monomer acrylamide and fully dissolve them in 4mL of acetone, and ultrasonicate for 120min in a 10mL colorimetric tube to fully generate template molecules and functional monomers function, then add 3.8mL (20mmol) crosslinking agent ethylene glycol dimethacrylate and 0.033g (0.2mmol) initiator azobisisobutyronitrile, ultrasonic 15min, after fully miscible, pass N 2Deoxidize for 10 minutes, seal immediately, and polymerize in a water bath at 55°C for 28 hours to obtain a rod-shaped polymer;

[0035] (2) Grind and sieve the obtained rod-shaped polymer, take 200-400 mesh polymer, and use a methanol solution with a volume ratio of 10% acetic acid to extract repeatedly in a Soxhlet extractor for 24 hours each time to remove template molecules and unreacted compounds, and then washed repeatedly with methanol for 5 hours each time to remove residual acetic acid to neutral until the eluate was detected by ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com