Method for preparing animal keratin base macromolecular hydrogel and application of hydrogel serving as medicine carrier

A technology based on polymers and animal horns, applied in the field of polymers, can solve the problems of few application results of keratin polymer materials, and achieve good swelling and deswelling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

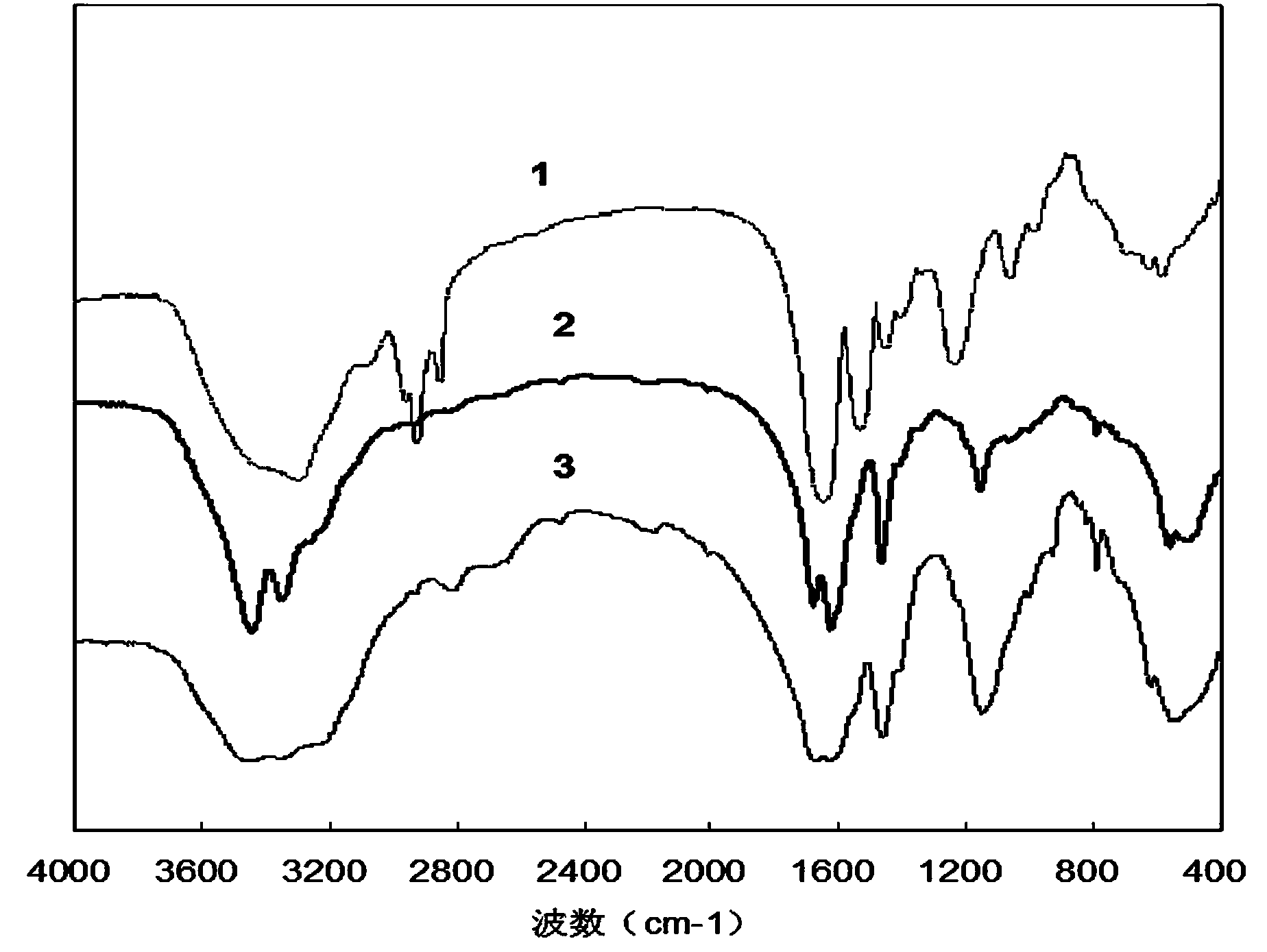

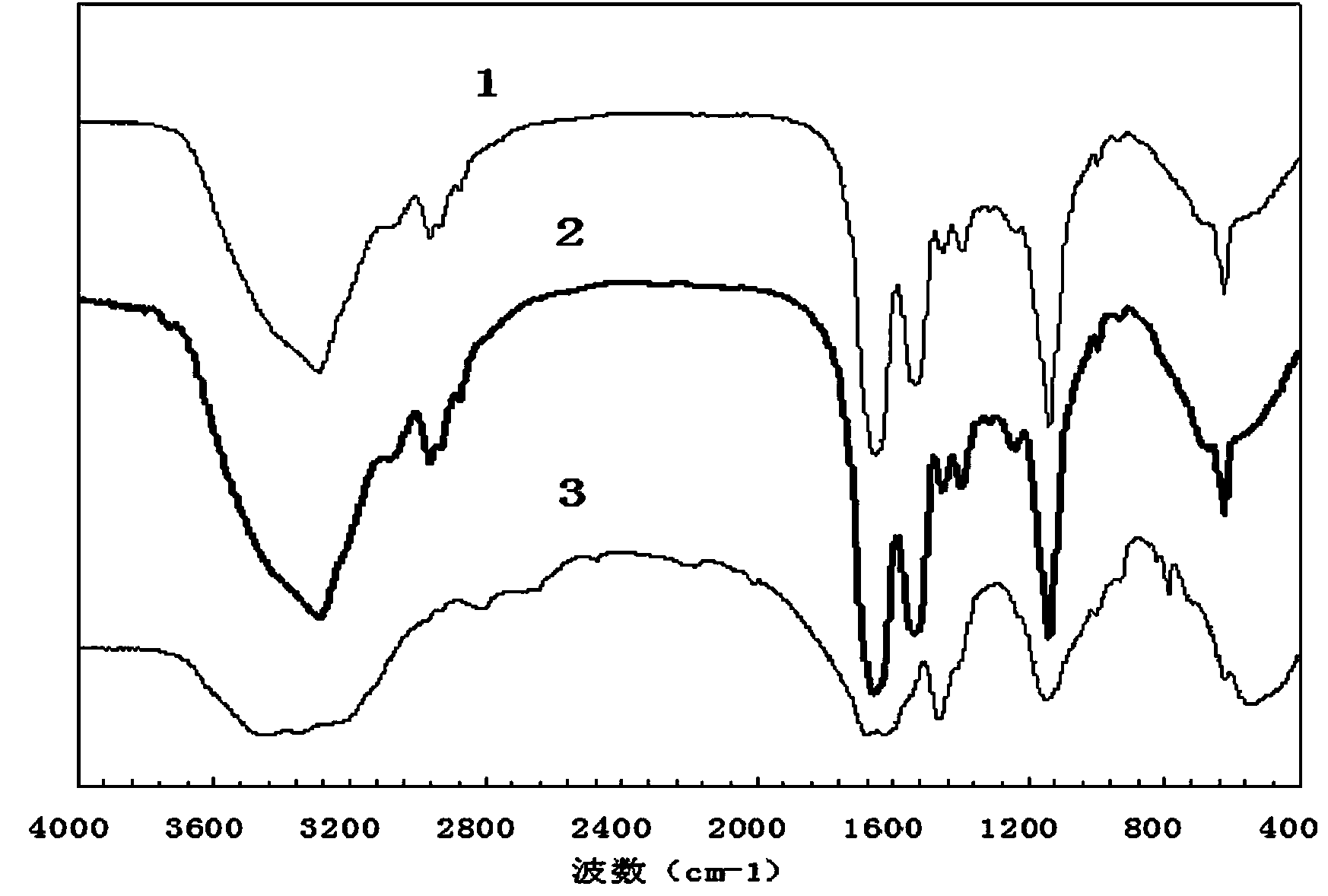

Image

Examples

Embodiment 1

[0042] Weigh 0.25 g of feather keratin powder, put it in a 100 mL three-necked bottle, add 25 mL of 8mol / L urea solution, stir and disperse at 45°C for 1 hour; blow nitrogen, add 0.005 g of dithiothreitol, and stir for 1 hour Finally, add 0.05g of ammonium persulfate and react for 40 minutes; add dropwise 2mL of methacrylic acid (neutralization degree 50%) neutralized with sodium hydroxide, and then add 0.25g of N,N'-methylenebisacrylamide React for 10 minutes, add 0.25g of sodium bicarbonate and stir evenly. After the bubbles in the mixed solution disappear, pour it into a 10mL glass vial and place it in a 60°C water bath to continue the reaction for 2 hours to form a hydrogel; Soak in ethanol for 24 hours (change the ethanol every 2 hours), and then soak in water for 24 hours (change the water every 2 hours), to get the feather keratin-based polymer hydrogel. The swelling rates of the hydrogel in physiological saline and aqueous glucose solution are 50 and 190 (g / g), respect...

Embodiment 2

[0044] Weigh 0.25 g of feather keratin powder into a 100 mL three-necked bottle, add 25 mL of 8mol / L urea solution, stir and disperse at 55°C for 1 hour; blow nitrogen, add 0.005 g of dithiothreitol, and stir for 1 hour, Add 0.05g of potassium persulfate and react for 40 minutes; add dropwise 2mL of methacrylic acid (neutralization degree 50%) neutralized with sodium hydroxide, and then add 0.25g of N,N'-methylenebisacrylamide to react After 10 minutes, add 0.25g of sodium bicarbonate and stir evenly. After the bubbles in the mixed solution disappear, pour it into a 10mL glass vial, place it in a water bath at 55°C and continue to react for 2 hours to form a hydrogel. Finally, dissolve the hydrogel in ethanol Soak in water for 24 hours (change the ethanol every 2 hours), and then soak in water for 24 hours (change the water every 2 hours), to get the feather keratin-based polymer hydrogel. The swelling rates of the hydrogel in physiological saline and aqueous glucose solution ...

Embodiment 3

[0046] Weigh 0.25 g of feather keratin powder into a 100 mL three-necked bottle, add 25 mL of 8mol / L urea solution, stir and disperse at 65°C for 1 hour; blow nitrogen, add 0.005 g of dithiothreitol, and stir for 1 hour, Add 0.05g of potassium persulfate and react for 40 minutes; add dropwise 2mL of methacrylic acid neutralized with sodium hydroxide (neutralization degree: 50%), and add 0.25g of N,N'-methylenebispropylene after the dropwise addition Amide reaction for 10 minutes, add 0.5g sodium bicarbonate, after the mixed solution is stirred evenly and the bubbles disappear, pour it into a 10ml glass vial, put it in a 70°C water bath and continue to react for 2 hours to form a hydrogel; finally put the hydrogel in Soak in ethanol for 24 hours (change the ethanol every 2 hours), and then soak in water for 24 hours (change the water every 2 hours), to get the feather keratin-based polymer hydrogel. The swelling rates of the hydrogel in physiological saline and aqueous glucose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Swelling rate | aaaaa | aaaaa |

| Swelling rate | aaaaa | aaaaa |

| Swelling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com