White carbon black high-activity dispersing agent composition and preparation method thereof

A high-activity, dispersant technology, applied in the field of silica high-activity dispersant composition and its preparation, can solve the problem of small dispersing function of silica, and achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

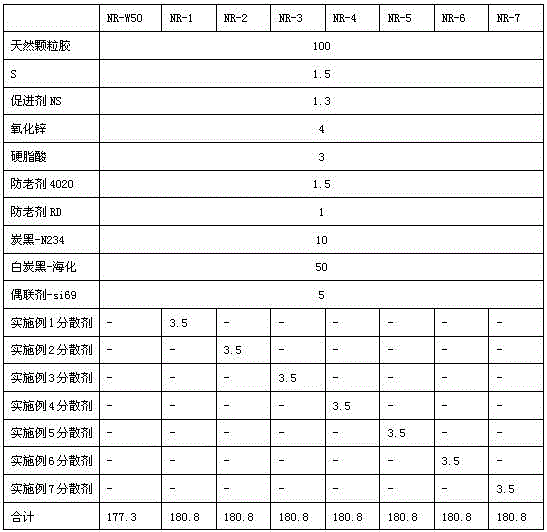

Embodiment 1

[0060] Weigh the raw materials by weight:

[0061] Acephenhydrazine 76 kg;

[0062] Lauric acid 60 kg;

[0063] Cetyltrimethylammonium chloride 18 kg;

[0064] Stearyl alcohol 8 kg;

[0065] 16 kg of monoglyceride;

[0066] Diethylene glycol 6 kg;

[0067] C9 petroleum resin 16 kg.

[0068] First put 60 kg of lauric acid, 18 kg of cetyl trimethyl ammonium chloride, 8 kg of stearyl alcohol, 16 kg of monoglyceride, 6 kg of diethylene glycol, and 16 kg of C9 petroleum resin to a pressure of -0.09Mpa In the negative pressure reactor, the reactor heats up. When the temperature rises to 160°C, 76 kg of acetophenazine are added to the reactor through the feeder. After the reaction is over, the high-activity silica dispersant combination can be prepared Discharge the white carbon black high-activity dispersant composition in the reaction kettle into the storage tank of the condensation granulator to form granules or flakes.

Embodiment 2

[0070] Weigh the raw materials by weight:

[0071] 62 kg of benzoyl hydrazide;

[0072] Benzenesulfonyl hydrazide 16 kg;

[0073] 54 kg of oleic acid;

[0074] Palmitic acid 40 kg;

[0075] Cetyl trimethyl ammonium chloride 10 kg;

[0076] Diethylene glycol 6 kg;

[0077] 12 kg of monoglyceride;

[0078] Stearyl alcohol 6 kg;

[0079] C9 petroleum resin 14 kg.

[0080] First put 54 kg of oleic acid, 40 kg of palmitic acid, 10 kg of cetyl trimethyl ammonium chloride, 6 kg of diethylene glycol, 12 kg of monoglyceride, 6 kg of stearyl alcohol, and 14 kg of C9 petroleum resin. In a negative pressure reaction kettle with a pressure of -0.09Mpa, the reaction kettle heats up. When the temperature rises to 180°C, 62 kg of benzoyl hydrazide and 16 kg of benzene sulfonyl hydrazide are added to the reaction kettle through the feeder. After the reaction is completed , The high-active white carbon black dispersant composition can be prepared, and the high-active white carbon black dispersant compositio...

Embodiment 3

[0082] Weigh the raw materials by weight:

[0083] Acephenhydrazine 38 kg;

[0084] Lauric acid 30 kg;

[0085] Monoglyceride 8 kg;

[0086] Cetyltrimethylammonium chloride 9 kg;

[0087] Stearyl alcohol 4 kg;

[0088] C9 petroleum resin 8 kg;

[0089] Diethylene glycol 3 kg.

[0090] First put 30 kg of lauric acid, 8 kg of monoglyceride, 9 kg of cetyl trimethyl ammonium chloride, 4 kg of stearyl alcohol, 8 kg of C9 resin, and 3 kg of diethylene glycol to a pressure of -0.09Mpa In the negative pressure reactor, the reactor heats up. When the temperature rises to 170°C, 38 kg of acetophenazine are added to the reactor through the feeder. After the reaction is completed, the white carbon black high-activity dispersant composition can be prepared , The white carbon black high-activity dispersant composition in the reaction kettle is discharged into the storage tank of the condensation granulator to make granules or flakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com