Complex microbial inoculant for greenhouse vegetable production and preparation and application thereof

A compound bacterial agent and vegetable technology, applied in the directions of microorganism-based methods, biochemical equipment and methods, applications, etc., can solve the problems of cumbersome use methods, and achieve the effect of long peak maintenance time, beneficial to plant absorption, and improvement of soil quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

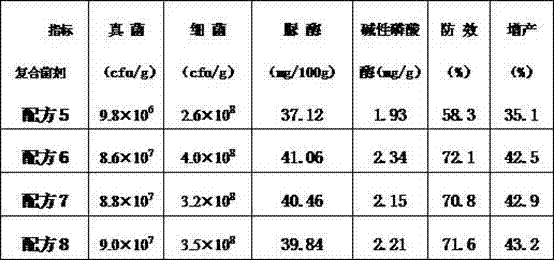

Examples

Embodiment Construction

[0022] 1. Composition and preparation of compound bacterial agent:

[0023] 1. Composition and preparation of liquid bacteria:

[0024] Trichoderma koningeni (Trichoderma koningii), Mucor racemosa (Mucor racemosus), Bacillus subtilis (Bacillus cereus. Frankland) The test tube slant culture medium is respectively inoculated in the corresponding liquid culture medium, and liquid strains are respectively made into liquid strains through liquid fermentation;

[0025] The weight composition of Trichoderma korningen culture medium: corn flour 2.0g, yeast extract 1.0g, potassium dihydrogen phosphate 0.05g, magnesium sulfate 0.05g, calcium chloride 0.01g, water 100ml, pH natural.

[0026] The weight composition of Bacillus subtilis medium: glucose 2.0g, peptone 1.5g, sodium chloride 0.5g, beef extract 0.05g, agar 2.0g, water 100ml, pH natural.

[0027] The weight composition of Mucor racemosus culture medium: 3.0g peptone, 0.4g soluble starch, 0.2g magnesium sulfate, 0.2g potas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com