Single photon emitter and manufacturing method thereof based on high refractive index contrast grating structure

A technology with high refractive index contrast and grating structure, which is applied in the direction of phonon exciters, lasers, laser components, etc., to achieve the effect of enhancing outgoing light, reducing difficulty, and increasing the wavelength adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

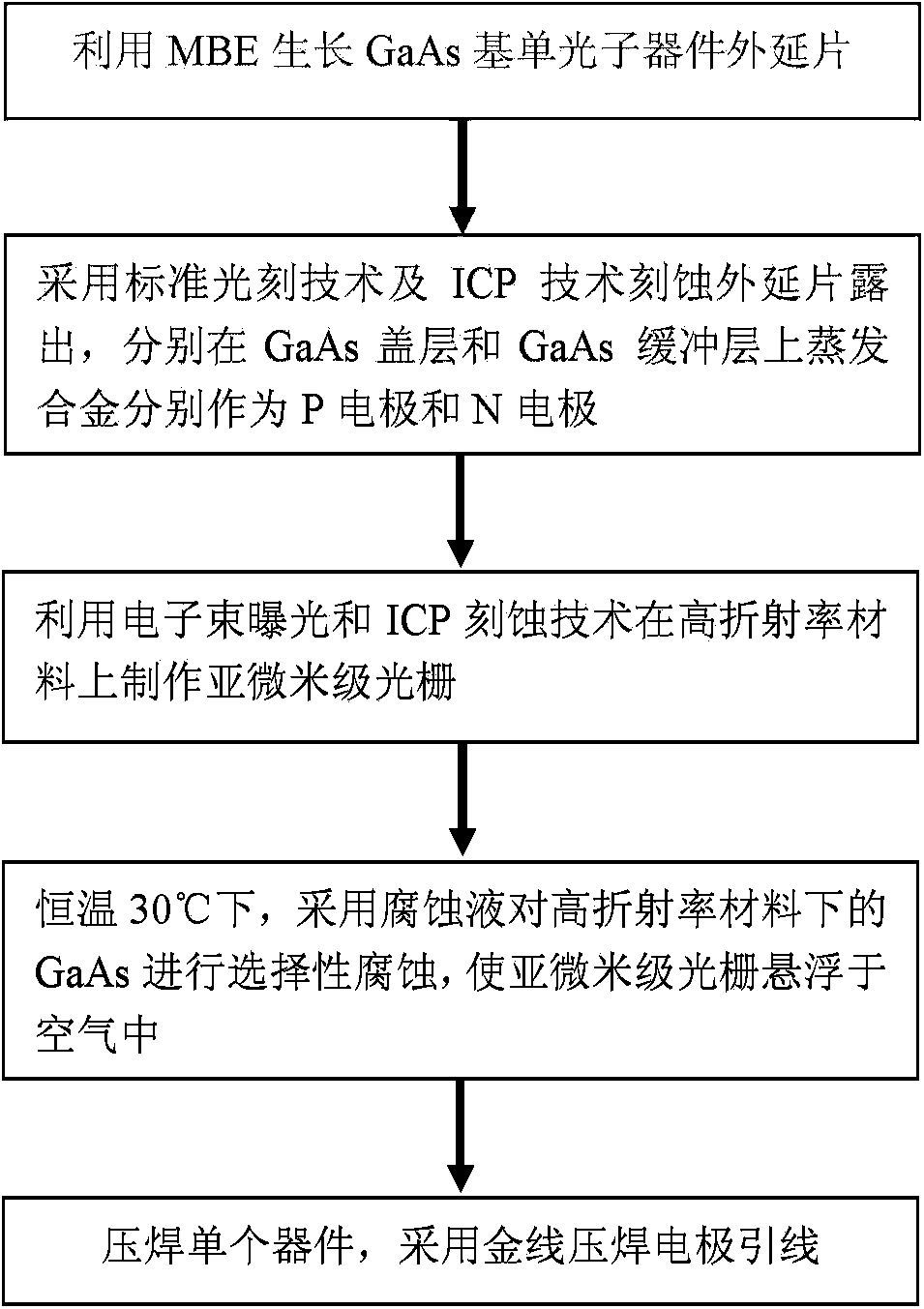

[0021] The single photon emitter based on the high refractive index contrast grating structure provided by the present invention first grows high-quality device epitaxial wafers on the GaAs substrate by molecular beam epitaxy technology, then uses surface emission technology to make electrodes, and finally uses electron beam Exposure produces a grating structure.

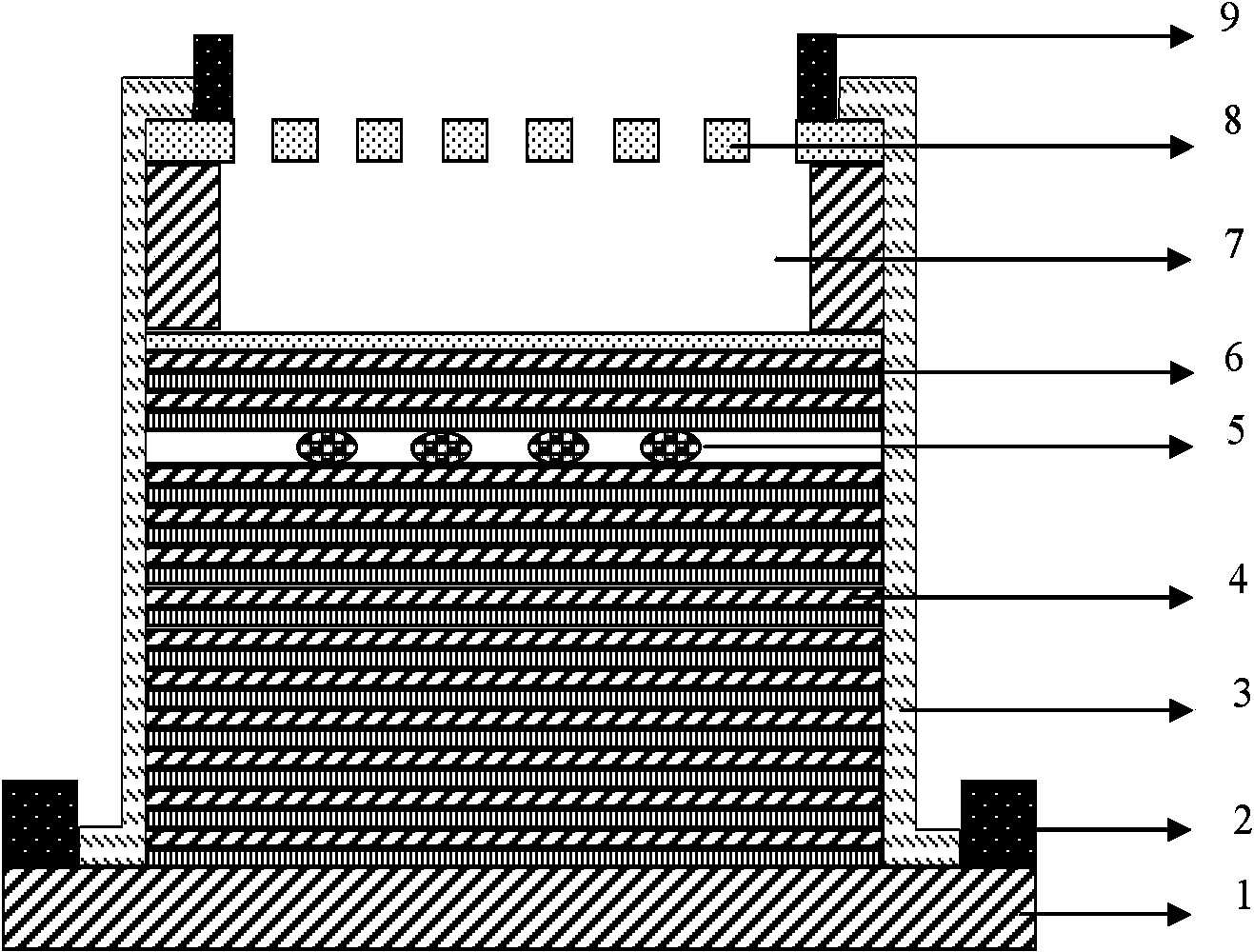

[0022] figure 1 It is a structural schematic diagram of a single photon emitter based on a high refractive index contrast grating structure provided by the present invention. Such as figure 1 As shown, the single photon emitter includes: GaAs buffer layer 1, N-type electrode 2, silicon dioxide passivation layer 3, lower DBR4, InAs quantum dot active region 5,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com