Adsorbing material prepared from waste straws and capable of adsorbing trivalent arsenic from water as well as preparation method and application thereof

A technology for waste straws and adsorption materials, which is applied in adsorption water/sewage treatment, chemical instruments and methods, and other chemical processes, etc., can solve the problems of lack of economy, complex preparation process, low adsorption capacity, etc. The effect of simple synthesis steps and easy availability of reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Pretreatment of straw

[0041] Wash the wheat straw (WS) with distilled water, dry it at 60°C, cut it into small pieces of about 0.5-0.8mm, and put it into 1%Na 2 CO 3 and 1% NaCl mixture, ultrasonic cleaning 2h. After taking it out, wash it with distilled water and dry it at 60°C for later use.

[0042] (2) Quaternization reaction

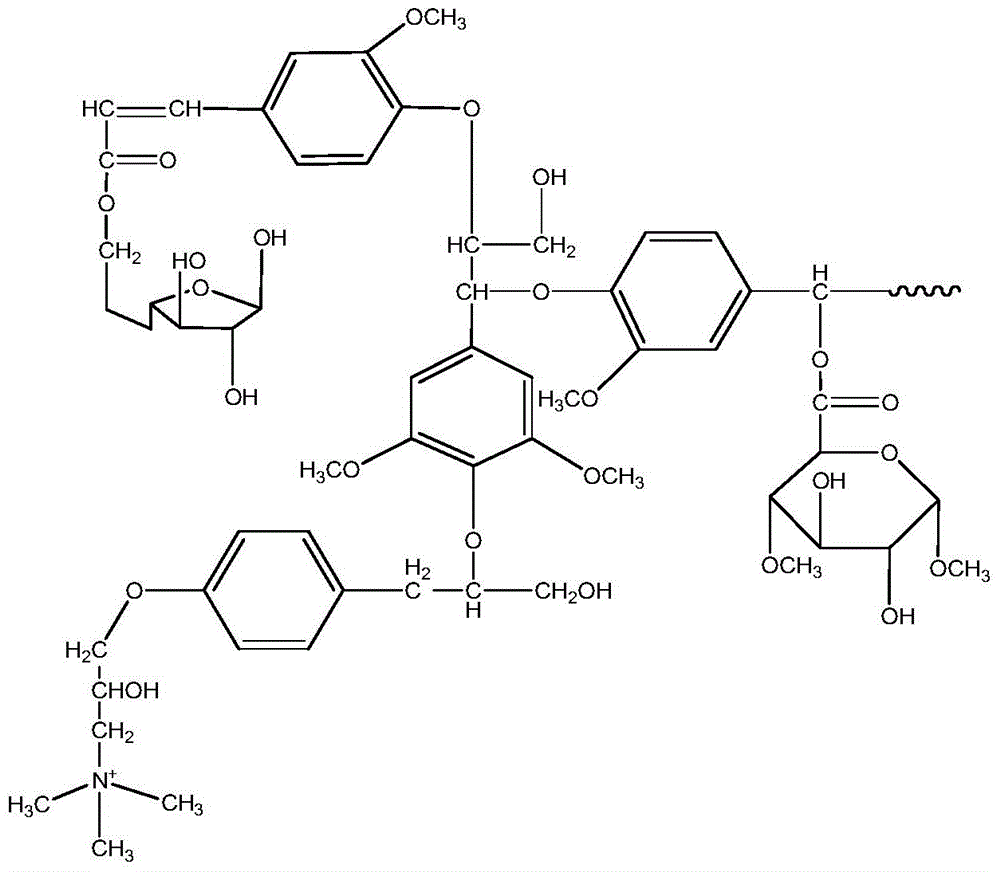

[0043] Put 2 g of wheat straw into a three-necked flask, add 30 mL of Quat188 (50% aqueous solution), 30 mL of 3M sodium hydroxide solution, heat in a water bath at 80 °C for 12 h, cool and filter, wash with distilled water until neutral, and dry in vacuum at 60 °C to obtain The wheat straw material WS-N modified by quaternary ammonium salt can be used to adsorb arsenic (Ⅲ), and the structural formula of WS-N is as follows figure 1 Shown:

[0044]

[0045] Its physical and chemical properties are as follows:

[0046] Nitrogen content (%)

Water absorption (mass ratio)

1.42

5.73

[0047] (3) Static...

Embodiment 2

[0055] (1) Pretreatment of straw

[0056] Wash the rice straw (WS) with distilled water, dry it at 60°C, cut it into small pieces of about 0.5-0.8mm, and then put it into 2%Na 2 CO 3 and 2% NaCl mixture, ultrasonic cleaning 3h. After taking it out, wash it with distilled water and dry it at 50°C for later use.

[0057] (2) Quaternization reaction

[0058] Put 2 g of rice straw into a three-necked flask, add 34 mL of Quat188 (60% aqueous solution), 30 mL of 4M sodium hydroxide solution, heat in a water bath at 75 °C for 14 h, cool and filter, wash with distilled water until neutral, and dry under vacuum at 40 °C to obtain The physical and chemical properties of quaternary ammonium salt modified rice straw material WS-N are as follows:

[0059] Nitrogen content (%)

Water absorption (mass ratio)

1.55

5.82

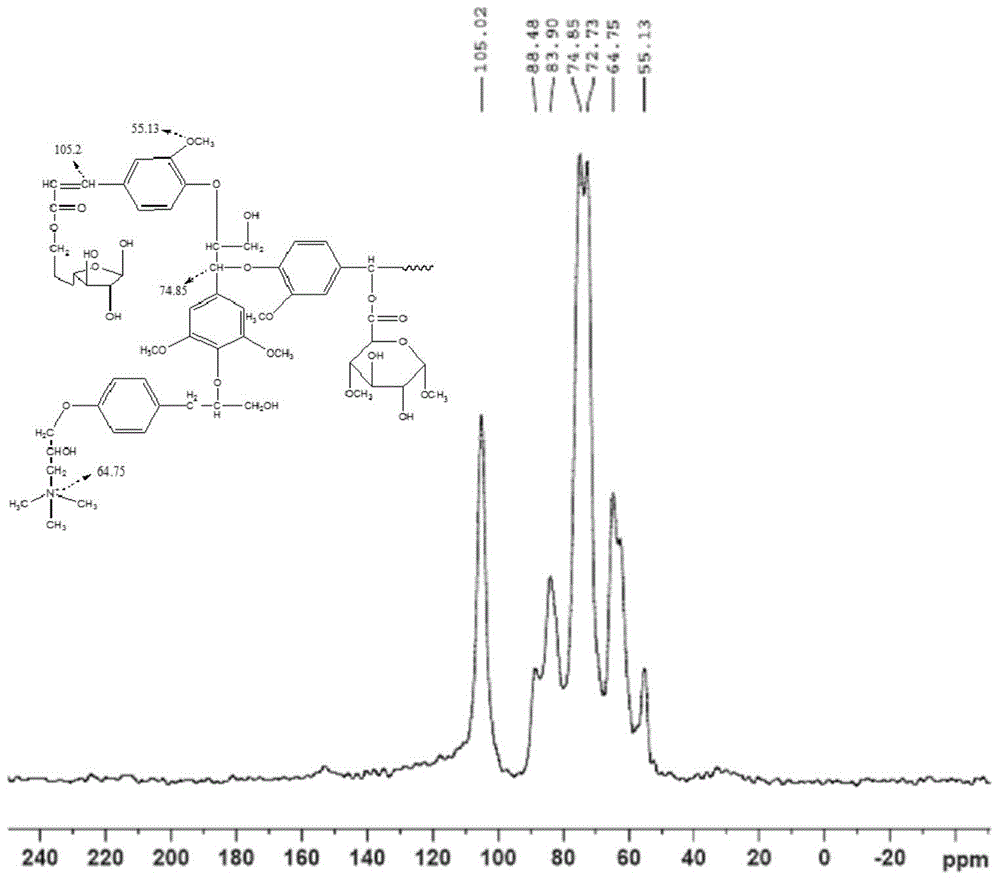

[0060] figure 2 It is the solid nuclear magnetic resonance spectrum of the adsorbent material WS-N prepared in embodiment 2 13 CNMR and ...

Embodiment 3

[0068] (1) Pretreatment of straw

[0069] Wash corn stalks (WS) with distilled water, dry at 60°C, cut into small pieces of about 0.5-0.8mm, and then put them into 3% Na 2 CO 3 and 3% NaCl mixture, ultrasonic cleaning 2.5h. After taking it out, wash it with distilled water and dry it at 40°C for later use.

[0070] (2) Quaternization reaction

[0071] Put 2g of corn stalks into a three-necked flask, add 36mL of Quat188 (70% aqueous solution), 30mL of 5M sodium hydroxide solution, heat in a water bath at 70°C for 16h, cool and filter, wash with distilled water until neutral, and dry under vacuum at 50°C to obtain a quaternary amine The salt-modified corn stalk material WS-N can be used to adsorb arsenic(Ⅲ), and its physical and chemical properties are as follows:

[0072] Nitrogen content (%)

Water absorption (mass ratio)

1.65

5.61

[0073] Figure 4 It is the XPS analysis diagram of the adsorption material WS-N prepared in Example 3, the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com