Amidoxime-modified polyacrylonitrile nanofiber membrane bimetallic complex catalyst and preparation method thereof

A technology of nanofiber membrane and polyacrylonitrile, which is applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve good adaptability, easy industrial promotion, and good catalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Pretreatment of ordinary polyacrylonitrile fibers: immerse polyacrylonitrile yarns in a 1:1 mixed solution of ethanol and water at 25°C for 30 minutes, take them out and dry them in vacuum at 50°C for 3 hours for later use;

[0037] 2. The spinning of polyacrylonitrile nanofiber film: the polyacrylonitrile yarn of the described pretreatment of 16.0g accurately weighed, and it is immersed in the N of 84.0g, N-dimethylformamide solvent dissolves completely A polyacrylonitrile spinning solution with a mass fraction of 16.0% was prepared. The spinning of polyacrylonitrile nanofiber membrane was carried out on a self-made electrospinning device. By controlling the extrusion rate (0.60ml / h) of the spinning solution and the voltage (25kV) at the needle, the spinning solution was ejected from the needle and Drafting forms a white polyacrylonitrile nanofiber film on the surface of the rotating disk, wherein the fiber diameter is measured by Image-Pro Plus6.0 software as 510.3...

Embodiment 2

[0044] 1, 2, 3, 4 and 6 steps of technology are respectively the same as 1, 2, 3, 4 and 6 steps of technology in Example 1.

[0045] 5. Preparation of mixed aqueous solution of metal ions: use ferric chloride and copper sulfate to prepare a mixed aqueous solution of metal ions with a molar concentration of 0.1M. The molar concentration ratio of iron ions to copper ions in the mixed aqueous solution is required to be 3:1, and then After the resulting mixed solution was left to stand for 4 hours, it was filtered for subsequent use;

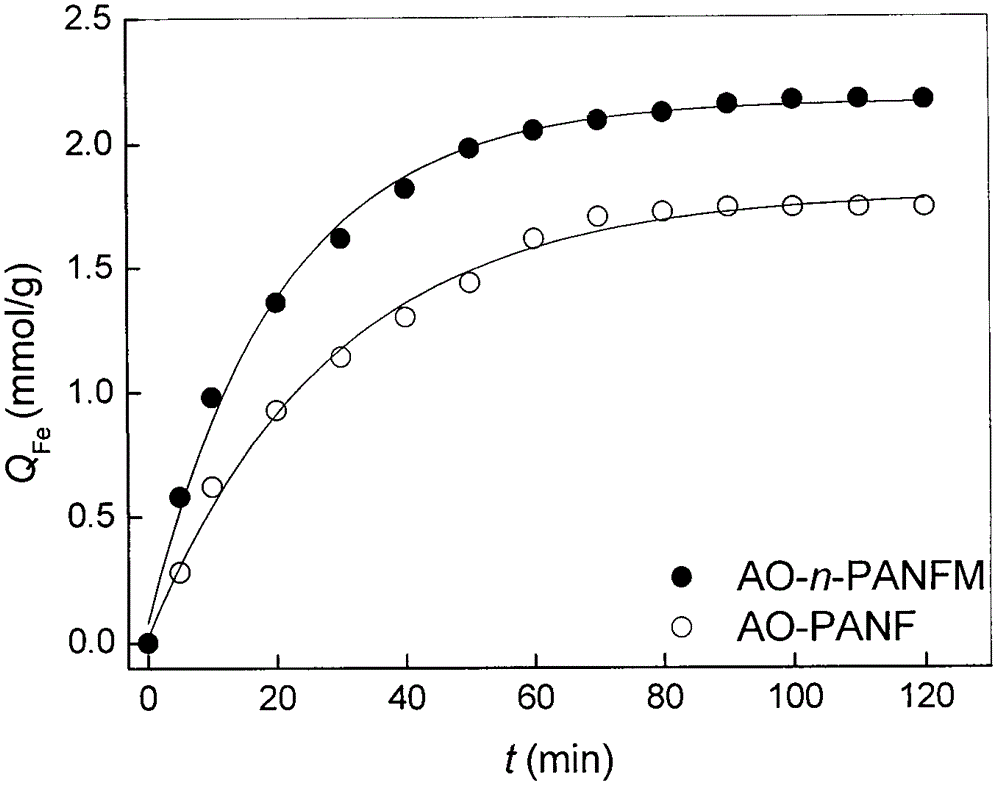

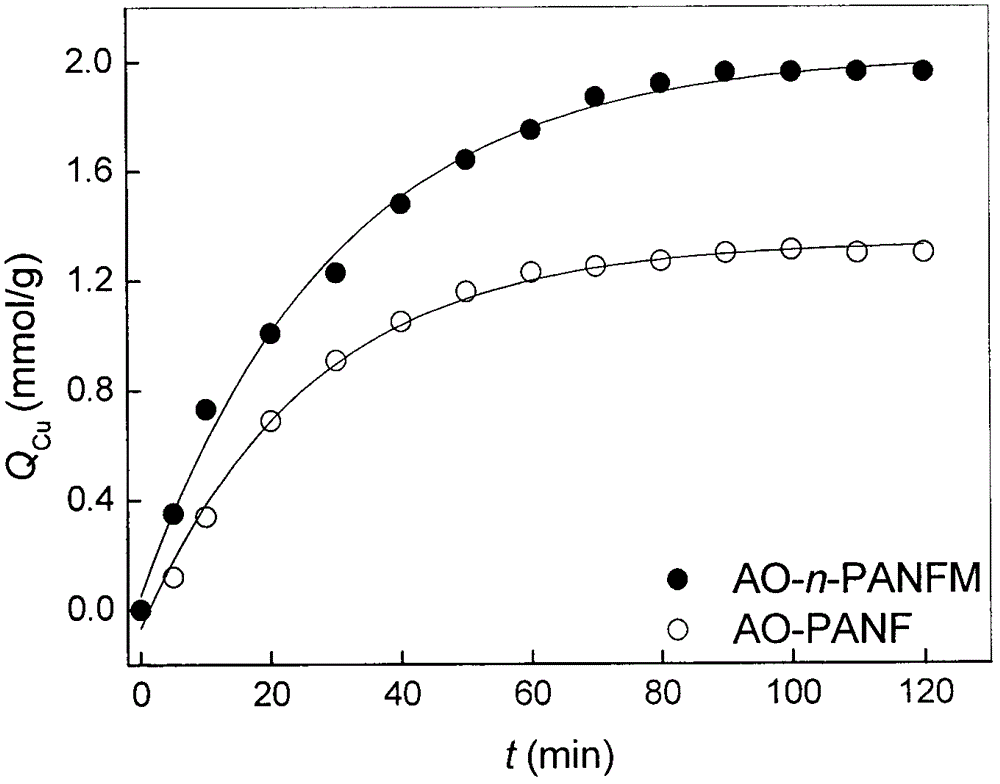

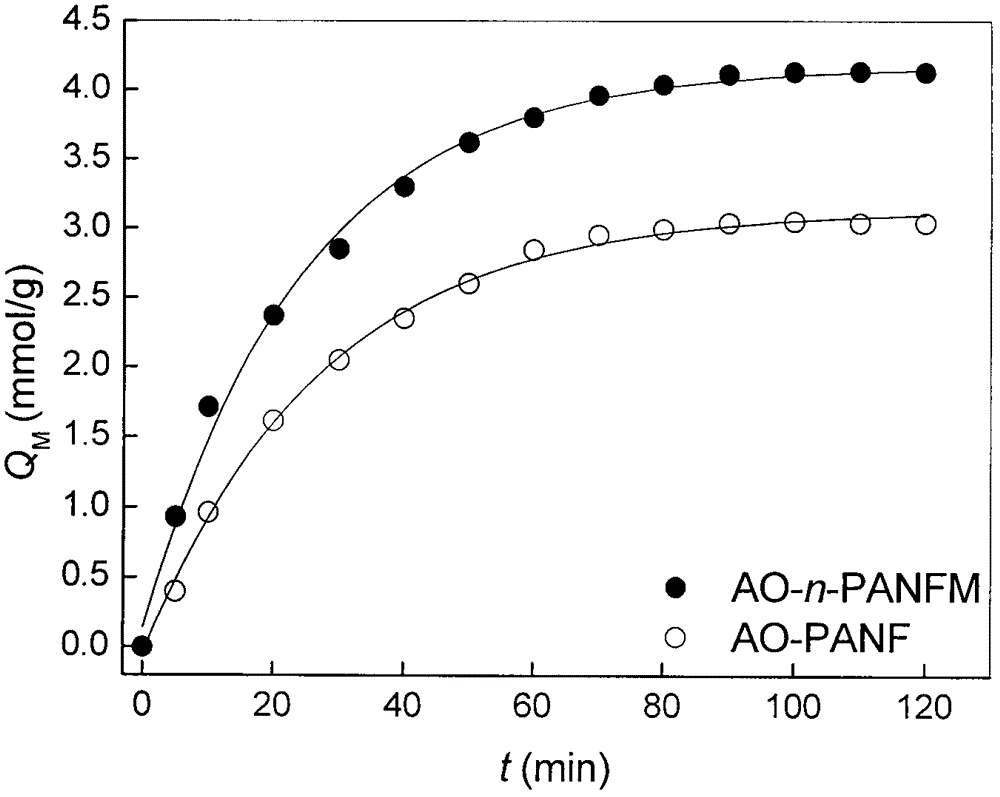

[0046] The prepared second amidoxime-modified polyacrylonitrile nanofiber membrane bimetallic complex catalyst (referred to as Fe-Cu-AO-n-PANFM-2) is brown in color. After measurement and calculation, the contents of iron ions and copper ions in the catalyst are 3.15mmol / g and 1.01mmol / g respectively.

Embodiment 3

[0048] 1, 2, 3, 4 and 6 steps of technology are respectively the same as 1, 2, 3, 4 and 6 steps of technology in Example 1.

[0049] 5. Preparation of mixed aqueous solution of metal ions: use ferric chloride and copper sulfate to prepare a mixed aqueous solution of metal ions with a molar concentration of 0.1M. The molar concentration ratio of iron ions to copper ions in the mixed aqueous solution is required to be 1:3, and then After the resulting mixed solution was left to stand for 4 hours, it was filtered for subsequent use;

[0050] The prepared third amidoxime-modified polyacrylonitrile nanofiber membrane bimetallic complex catalyst (referred to as Fe-Cu-AO-n-PANFM-3) is brown. Through measurement and calculation, the contents of iron ions and copper ions in the catalyst are 1.03mmol / g and 3.07mmol / g respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com