Heteroatom-containing organic microporous material as well as preparation and application thereof

A technology of microporous materials and heteroatoms, which is applied in the field of organic microporous materials containing heteroatoms, can solve the problems of poor thermal stability and achieve the effects of large adsorption capacity, uniform pore size distribution, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of compound 2

[0043] Under the protection of argon, add PdCl to a dry two-necked flask equipped with magnetic stirring 2 (PPh 3 ) 2 (1.71g, 2.44mmol), cuprous iodide (0.77g, 4mmol), m-bromoiodobenzene (11.5g, 40.4mmol), DBU (36.8g, 241.7mmol) and benzene 50mL, placed in an oil bath at 35°C Stir, add trimethylsilylacetylene (2.84 mL, 20.4 mmol) and 280 μL of water to the reaction flask with a syringe, and react at this temperature for 24 hours. Cool to room temperature, filter the filtrate with suction, wash the filter cake with cold dichloromethane, and recrystallize with toluene to obtain a white solid. The product dissolved in dichloromethane solvent is washed with water, salt, and anhydrous MgSO 4 After drying, vacuum filtration, the solvent was evaporated, and dichloromethane was added to dissolve, and then separated and purified by column chromatography (stationary phase: silica gel; eluent: petroleum ether) to obtain 5.07 g of white solid with a yield o...

Embodiment 2

[0046] Preparation of compound 3

[0047] Under argon protection, add compound 2 (0.75g, 2.23mmol), 2-thiophene boronic acid (0.63g, 4.92mmol), Pd(PPh 3 ) 4 (0.39g, 0.34mmol), 30mL of potassium carbonate (1M) and THF (30mL) were added. Heat to reflux and react for 24 hours. TLC tracked the completion of the reaction and stopped the reaction. After cooling to room temperature, the mixture was extracted with dichloromethane (70mL×3), and the organic layer was washed with water (50mL×3) and anhydrous MgSO 4 dry. The solvent was evaporated, the dichloromethane was dissolved, and the column chromatography was separated and purified (eluent: petroleum ether) to obtain 0.61 g of white solid, with a yield of 79.9%.

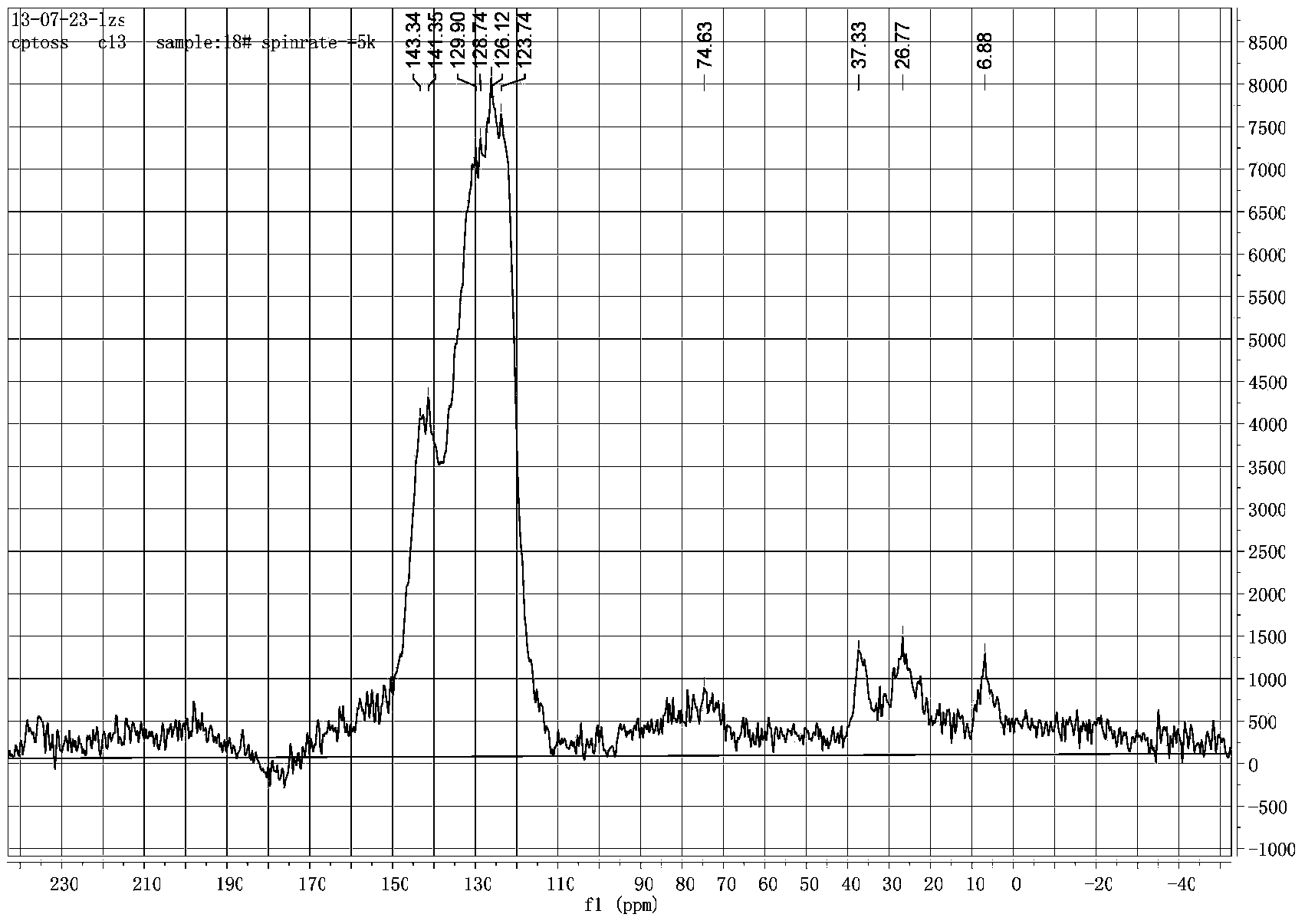

[0048] 1 H NMR(CDCl 3 , 400MHz): δ (ppm) 7.81 (s, 1H), 7.58 (m, 1H), 7.46 (m, 1H), 7.40 (m, 1H), 7.32 (m, 1H), 7.11 (m, 1H). 13 C NMR(CDCl 3 , 100MHz): δ (ppm) 143.44, 134.71, 130.57, 129.01, 128.13, 125.97, 125.29, 123.80, 123.61, 89.47. MS (EI): m / z (%) 171 (21), 342 (100)....

Embodiment 3

[0050] Preparation of compound 4

[0051] Under the protection of argon, add compound 3 (0.3g, 0.877mmol) and 1,4-dioxane (30mL) to a 50mL two-necked flask. After cooling for three times to remove oxygen, add dicobalt octacarbonyl (45mg, 0.13 mmol), heated to reflux, and reacted for 24 hours. The solvent was evaporated, the residue was dissolved in dichloromethane, and separated and purified by column chromatography (developing solvent: dichloromethane: petroleum ether=3:1) to obtain 0.22 g of white solid, with a yield of 73.3%.

[0052] MALDI-TOF mass[M + ]: Theoretical value: 1027.43, experimental value: 1026.9856.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com