A kind of preparation method containing methyl silicate graft polymer waterproofing agent

A technology of grafting polymer and methyl silicic acid, applied in the direction of coating, etc., to avoid particle agglomeration, low price and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of methyl silicate graft polymer:

[0026] First add 64g of methyl silicic acid, 72g of methacrylic acid, 150g of toluene, 1.5g of stannous octoate, and 0.34g of hydroquinone into a three-necked flask with a thermometer, a condenser and a stirring device, and slowly heat the above mixture to 90 ℃, react for 8 hours; after cooling, wash off unreacted monomers and polymerization inhibitors with sodium carbonate solution, add 106g styrene and 2.12g benzoyl peroxide after drying, heat up and slowly add 1.01g benzene peroxide dropwise Formyl solution, after dropwise addition, was reacted at a temperature of 60° C. for 4 hours, and the solvent was removed under reduced pressure to obtain a polymer.

[0027] Preparation of waterproofing agent:

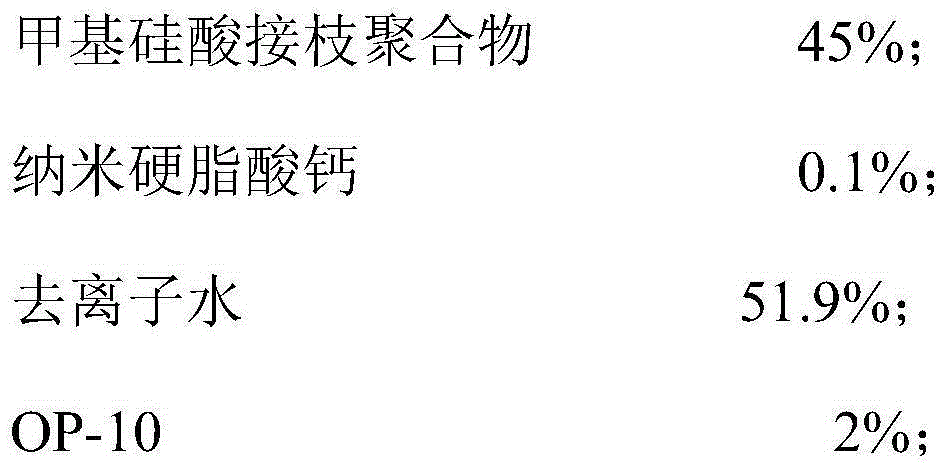

[0028] The waterproofing agent raw material formula is as follows by weight percentage:

[0029]

[0030] Waterproofing agent preparation process: Use KH550 to modify the surface of nano calcium stearate particles, the...

Embodiment 2

[0032] Preparation of methyl silicate graft polymer:

[0033] First add 64g of methyl silicic acid, 86.4g of methacrylic acid, 240g of toluene, 1.25g of stannous chloride, and 0.34g of hydroquinone into a three-necked flask with a thermometer, a condenser and a stirring device, and slowly heat the above mixture React at 120°C for 6 hours, wash with sodium carbonate solution to remove unreacted monomers and polymerization inhibitors after cooling, add 120g styrene and 2.62g tert-butyl peroxybenzoate after drying, heat up and slowly add 2.01g After the dropwise addition of the tert-butyl peroxybenzoate solution, react at a temperature of 60° C. for 4 hours, and remove the solvent under reduced pressure to obtain a polymer.

[0034] Preparation of waterproofing agent:

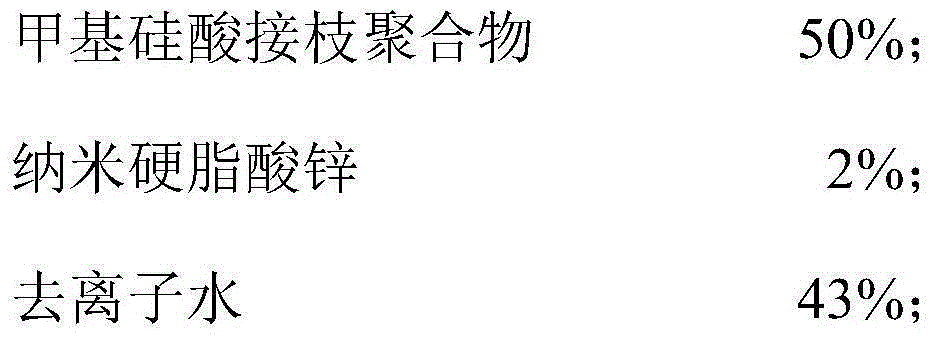

[0035] Waterproofing agent raw material formula by weight percentage:

[0036]

[0037]

[0038] Waterproofing agent preparation process: use KH570 to modify the surface of nano-zinc stearate particles, th...

example 3

[0040] Preparation of methyl silicate graft polymer:

[0041] First add 64g of methyl silicic acid, 108g of methacrylic acid, 320g of toluene, 2.6g of dibutyltin dilaurate, and 0.54g of hydroquinone into a three-necked flask with a thermometer, a condenser and a stirring device, and the above mixture Slowly heat to 110°C and react for 7 hours. After cooling, wash with sodium carbonate solution to remove unreacted monomers and polymerization inhibitors. After drying, add 106g of styrene and 312g of tert-butylcumyl peroxide, heat up and slowly add 2.15 g of tert-butylcumyl peroxide solution, after the dropwise addition, react at a temperature of 60° C. for 4 h, and remove the solvent under reduced pressure to obtain a polymer.

[0042] Preparation of waterproofing agent:

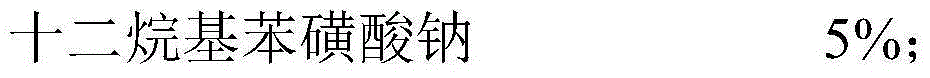

[0043] Waterproofing agent raw material formula by weight percentage:

[0044]

[0045] Waterproofing agent preparation process: use KH560 to modify the surface of nano-magnesium stearate particles, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com