Acid-base resistant polyether modified trisiloxane surfactant as well as preparation and application thereof

A surfactant, polyether modification technology, applied in transportation and packaging, organic silicon compounds, chemical instruments and methods, etc., can solve the problems of poor acid and alkali resistance, limited application range, surface tension increase, etc. Effects of hazardous substances, simple reaction steps, no or low VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

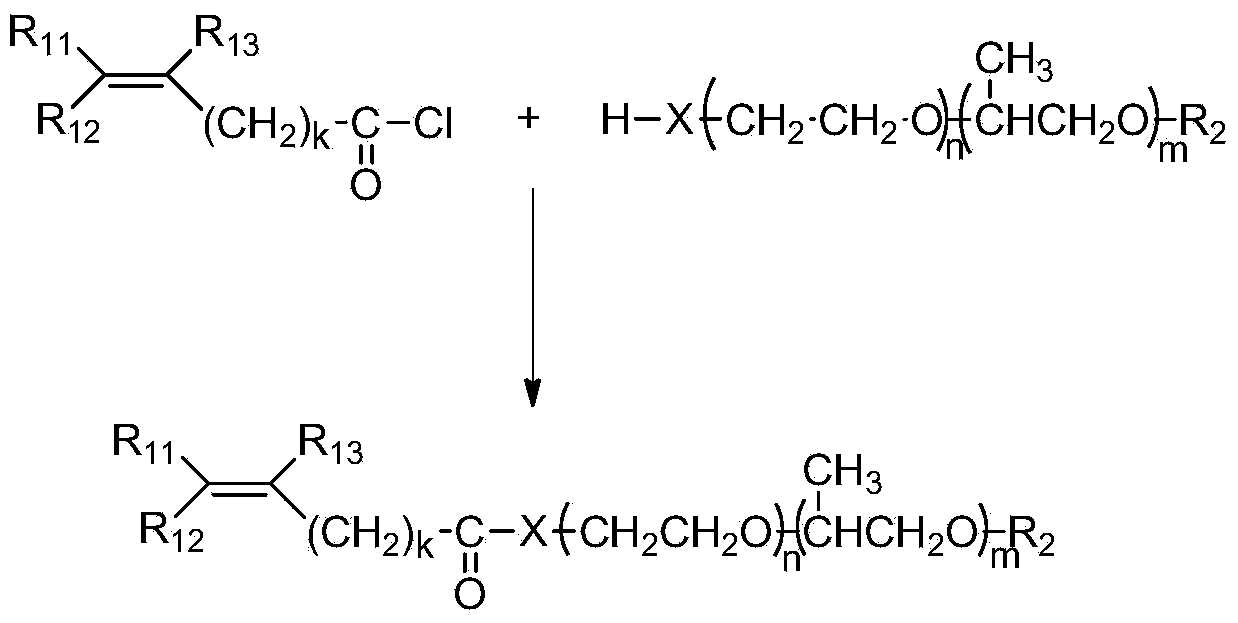

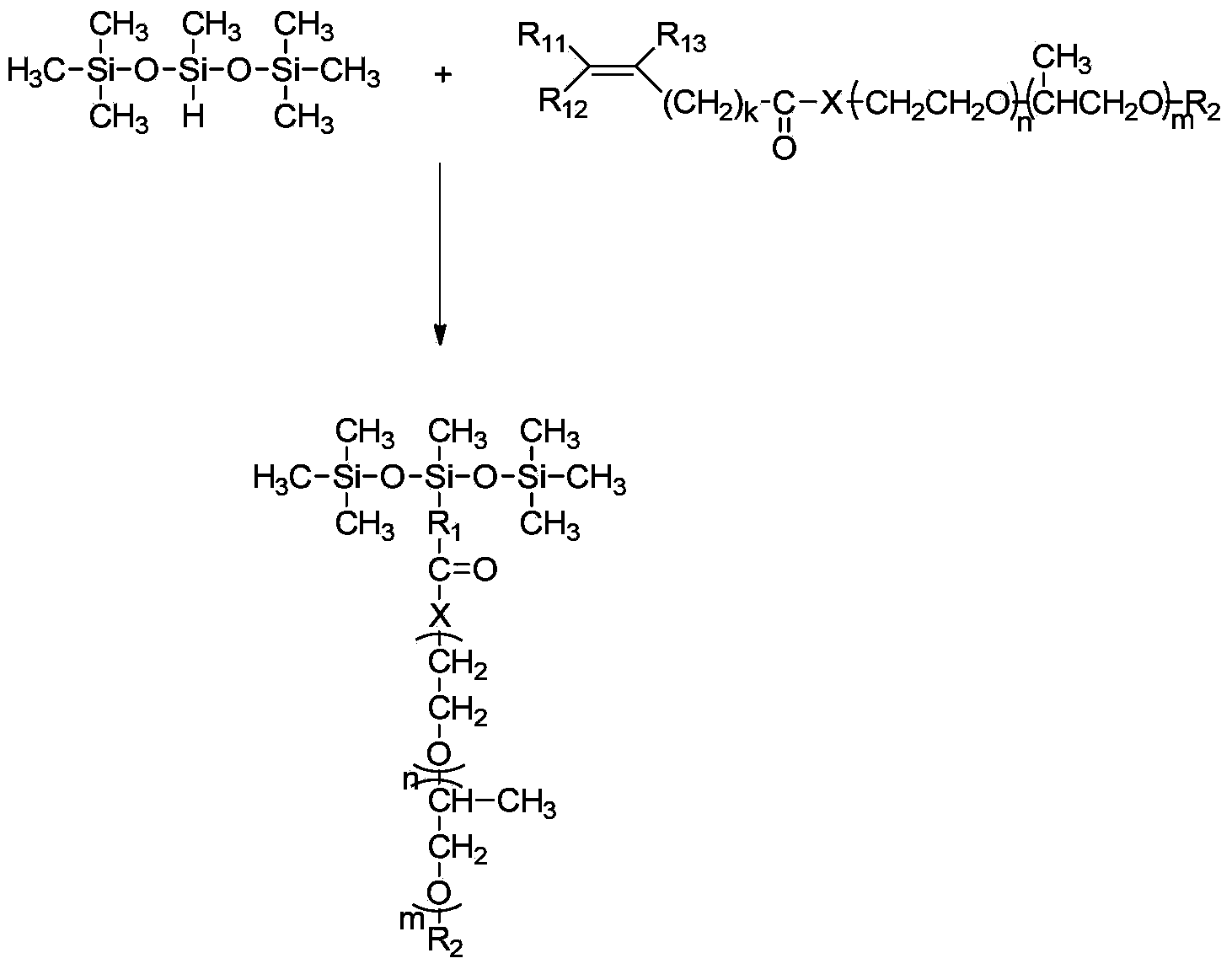

Method used

Image

Examples

Embodiment 1

[0030]Add polyethylene glycol monomethyl ether (M.W=350) (17.5g, 50mmol), triethylamine (6.06g, 60mmol) and CH 2 Cl 2 (100mL), magnetically stirred evenly, and acryloyl chloride (4.98g, 55mmol) and CH 2 Cl 2 (30mL) was added to the constant pressure dropping funnel, then placed in an ice bath to cool down to 0°C, and then the liquid in the constant pressure dropping funnel was slowly dropped into the three-necked flask, and after the ice bath was reacted for 1 hour, the The reaction was carried out for 4 hours, and the reaction was stopped. The insoluble matter was separated by suction filtration with a Buchner funnel, the organic phase was collected, washed with acid, alkali and saturated brine in sequence until neutral, and dried with anhydrous magnesium sulfate. The organic solvent was removed under vacuum to obtain a light yellow transparent liquid which was polyethylene glycol monomethyl ether acrylate (17.98 g, 89%).

[0031] 1 HNMR (400MHz, CDCl 3 ): 6.43 (d, 1H),...

Embodiment 2

[0037] Add polyethylene glycol monomethyl ether (M.W=350) (17.5g, 50mmol), triethylamine (6.06g, 60mmol) and CH 2 Cl 2 (100mL), magnetically stirred evenly, 2-butenoyl chloride (5.75g, 55mmol) and CH 2 Cl 2 (30mL) was added to the constant pressure dropping funnel, then placed in an ice bath to cool down to 0°C, and then the liquid in the constant pressure dropping funnel was slowly dropped into the three-necked flask, reacted in the ice bath for 1 hour, and then After reacting at room temperature for 4 hours, the reaction was terminated. The insoluble matter was separated by suction filtration with a Buchner funnel, the organic phase was collected, washed twice with acid water, twice with alkaline water, washed with saturated saline until neutral, and dried over anhydrous magnesium sulfate. The organic solvent was removed under vacuum to obtain polyethylene glycol monomethyl ether crotonate (20.6 g, 91%) as a light yellow transparent liquid.

[0029] 1 HNMR (400MHz, CDCl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com