Phosphor-less hexavalent chromium-less environmentally-friendly plastic electroplating method

A technology of plastic electroplating and hexavalent chromium, which is applied in hexavalent chromium-free plastic electroplating and environmentally friendly phosphorus-free fields. It can solve the problems of too many transition chambers, valves that cannot be locked, and disastrous ecology, etc., and achieves convenient equipment maintenance. , easy maintenance and replacement, strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

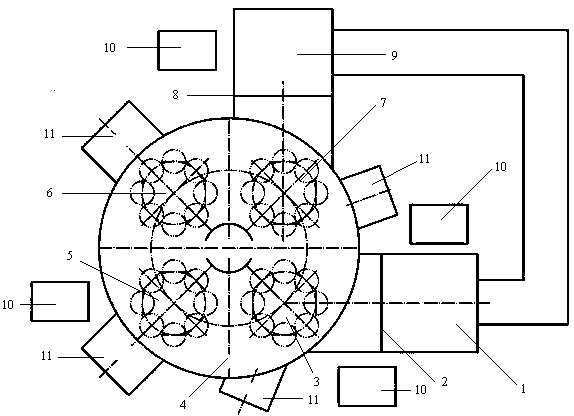

[0046] Example 1 Implementation of phosphorus-free, hexavalent chromium-free environmentally friendly plastic electroplating process on ABS (acrylonitrile, butadiene and styrene polymer) engineering plastic multifunctional shower shell

[0047] Specific steps are as follows:

[0048] 1) Put the PVD hanger on the ABS shower head injection molded blank, after cleaning the surface, dry it at 70°C for 3 hours;

[0049] 2) After drying, the hanger is transferred to the turntable, and the outer rail car pushes into the feeding bin, draws a low vacuum and starts the low-temperature water vapor trap to complete the pre-vacuum process.

[0050] 3) The first flapper valve is opened, and the turntable is pushed into the No. 1 station of the vacuum chamber by the pneumatic manipulator.

[0051] 4) The No. 1 station conducts low-temperature plasma surface modification at 30°C. The process conditions are ion source current: 0.3A, bias voltage: 200V, duty cycle: 50%, argon flow rate: 50SCCM...

Embodiment 2

[0059] Example 2 ABS+PC (polycarbonate) micro-boiler handle implements phosphorus-free, hexavalent chromium-free environmentally friendly plastic electroplating process

[0060] Specific steps are as follows:

[0061] 1) Put the micro-boiler handle on the injection-molded blank with PVD hanger, clean the surface, and dry at 80°C for 2 hours;

[0062] 2) After drying, the hanger is transferred to the turntable, and the outer rail car pushes into the feeding bin, draws a low vacuum and starts the low-temperature water vapor trap to complete the pre-vacuum process.

[0063] 3) The first flapper valve is opened, and the turntable is pushed into the No. 1 station of the vacuum chamber by the pneumatic manipulator.

[0064] 4) The No. 1 station is used for low-temperature plasma surface modification, and the process conditions are ion source current: 0.5A, bias voltage: 300V, duty cycle: 75%, argon flow rate: 150SCCM, oxygen flow rate: 100SCCM, vacuum in the furnace Pressure: 2.0P...

Embodiment 3

[0072] Example 3 Phosphorus-free and hexavalent chromium-free environmentally friendly plastic electroplating process for bathroom faucet shells made of PA (polyamide) + mineral powder

[0073] Specific steps are as follows:

[0074] 1) Put the PA + mineral powder bathroom faucet shell molding blank on the PVD hanger, clean the surface, and dry it at 120°C for 1 hour;

[0075] 2) After drying, the hanger is transferred to the turntable, and the outer rail car pushes into the feeding bin, draws a low vacuum and starts the low-temperature water vapor trap to complete the pre-vacuum process.

[0076] 3) The first flapper valve is opened, and the turret is pushed into the No. 1 station of the vacuum chamber by the pneumatic manipulator.

[0077] 4) The No. 1 station performs glow electrode cleaning. The process conditions are glow electrode voltage: 2500V, duty cycle: 100%, argon flow rate: 75SCCM, nitrogen flow rate: 100SCCM, vacuum pressure in the furnace: 0.7Pa, glow Time: 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com