Online real-time representation device for film epitaxial growth

A technology of epitaxial growth and characterization, applied in Raman scattering, material excitation analysis, etc., which can solve problems such as uncertainty, error, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

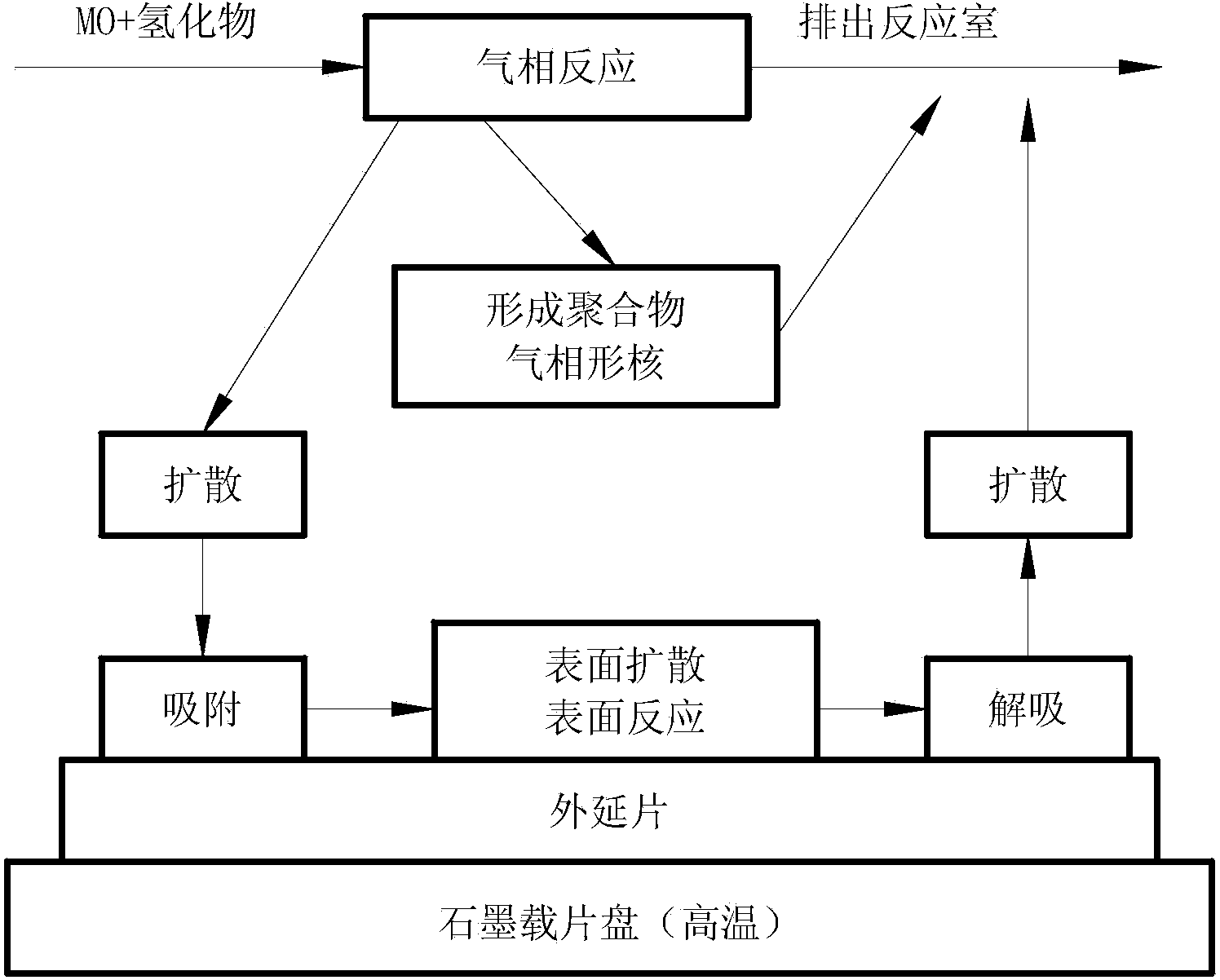

Method used

Image

Examples

Embodiment 1

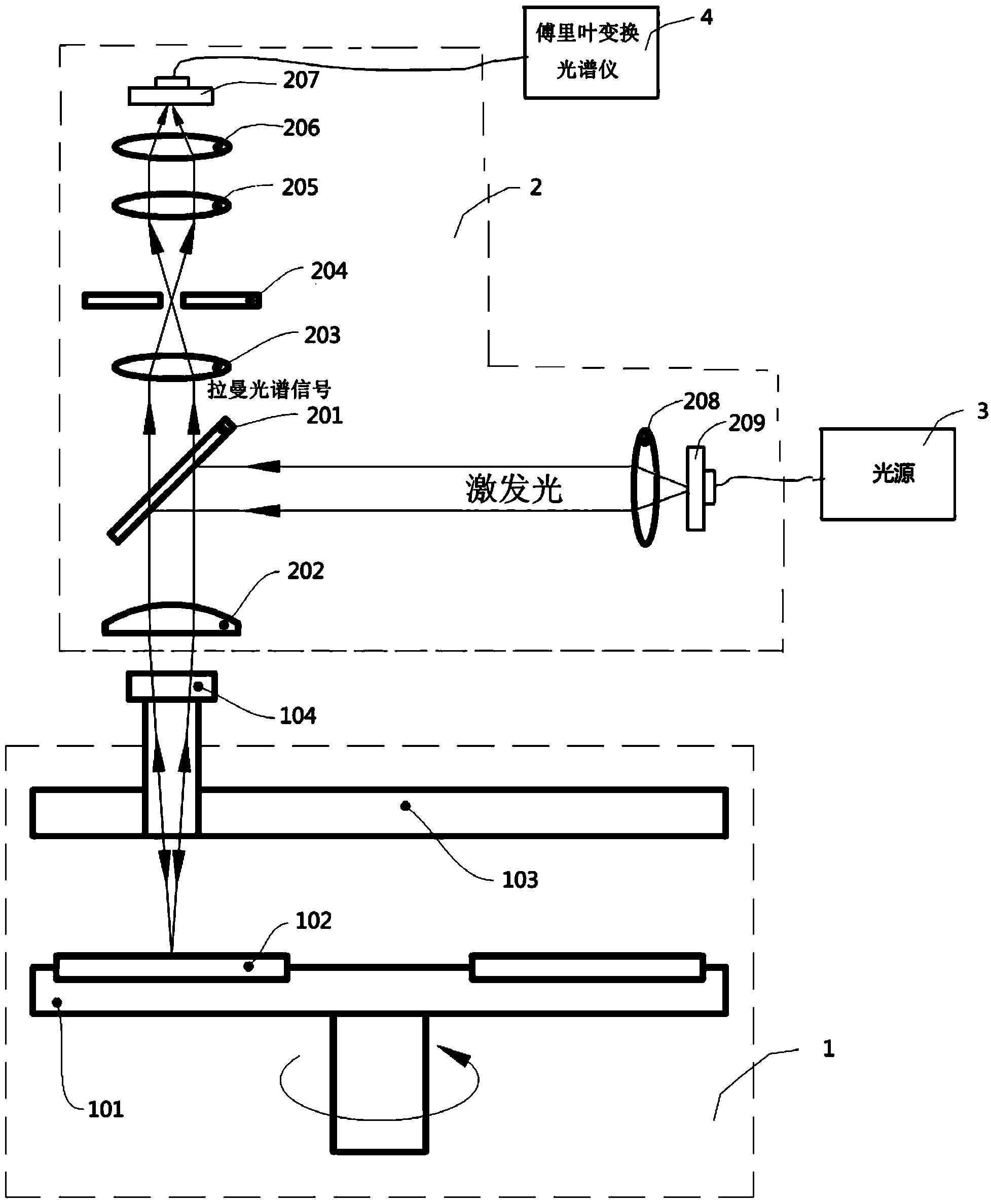

[0039] In this embodiment, as image 3 As shown, in order to achieve the above purpose of the invention, the online real-time characterization device for thin film epitaxial growth of the present invention includes a probe 2, a light source 3 and a Michelson interferometer 4;

[0040] The probe 2 includes a first beam splitter 201, a plano-convex lens 202, a first focusing lens 203, a confocal pinhole 204, a first collimating lens 205 and a second focusing lens 206; the light source 3 emits monochromatic excitation light After entering the probe 2 through the fiber coupler 209, it is transformed into parallel light by the straight lens 208, and after being reflected by the first beam splitter 201, it is focused by the plano-convex lens 202, and the focusing point is irradiated on the observation window 104 at the top of the MOCVD reaction chamber 1. On the epitaxial wafer 102 ; the Raman spectrum signal excited by the irradiated area of the epitaxial wafer focusing point is co...

Embodiment 2

[0044] In this embodiment, on the basis of Embodiment 1, further improvements are made to enable online acquisition of reflection spectra and thermal radiation spectra. The reflected beam contains a large number of epitaxial wafer growth signals: reflecting the quality of surface atomic reconstruction , The reflection spectrum of the thickness of the epitaxial layer, and the thermal radiation spectrum of the temperature of the epitaxial wafer.

[0045] The Raman spectrum signal generated by the epitaxial wafer and the reflected beam including the reflection spectrum and the thermal radiation spectrum are divided into two beams by the first beam splitter 201 after passing through the plano-convex lens 202, one beam is transmitted for Raman spectrum detection, and the other beam is used for Raman spectrum detection. After reflection, it propagates in the opposite direction of the excitation light, such as Figure 4 shown. In the present invention, a second beam splitter 210 is ...

Embodiment 3

[0048] 1. Use the reflected spectral signal to accurately and repeat the positioning for the measurement of the Raman spectrum

[0049] Although the reflectivity of the epitaxial wafer 102 varies with the growth thickness, the reflectivity of the epitaxial wafer 102 is much higher than that of the graphite wafer plate 101 compared to the graphite wafer plate, so the measured reflection spectrum signal is the same as the graphite plate. The rotation of the slide disc 101 fluctuates, such as Figure 5 shown.

[0050] In the MOCVD process, in order to make the growth quality of the epitaxial wafer 102 as uniform as possible, the MOCVD equipment controls the rotation speed of the graphite carrier disk 101 very smoothly. Therefore, in this embodiment, on the basis of Embodiment 2, further improvements are made. The reflection spectrum signal detected by the detector 5 is analyzed in real time to obtain the relationship between the reflection spectrum fluctuation and the angular di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com