Multi-layer drug sustain-release nano fiber membrane and preparation method thereof

A nanofiber film and nanofiber technology, which is applied in the direction of drug combination, antibacterial drugs, antineoplastic drugs, etc., to achieve the effect of good shape, prolonged action time and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Dissolve the weighed CA and CM in a mixed solvent of acetone and dimethylacetamide (volume ratio 3:2), and prepare the CA concentration to be 13%, and the CM concentration to be 10% to 30% (w / w) drug-loaded spinning solution, the weighed PLA was dissolved in the mixed solvent of dichloromethane and dimethylformamide (volume ratio 7: 3), and the spinning solution with 8% PLA concentration was prepared .

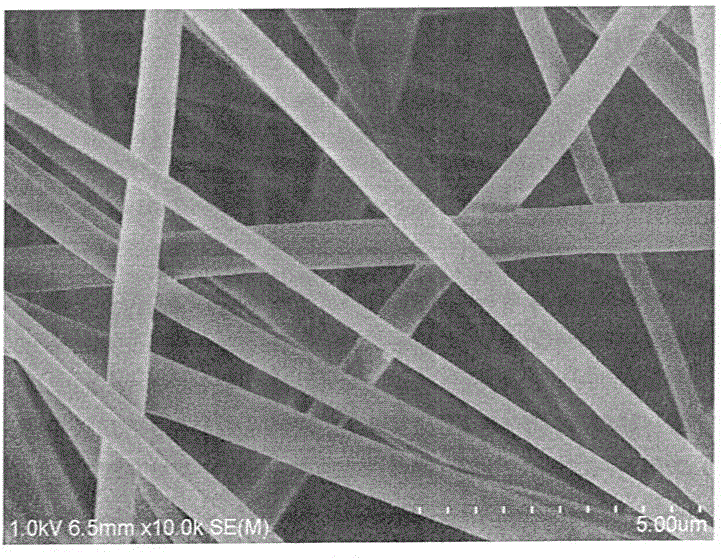

[0020] (2) Inject the PLA spinning solution into the syringe of the electrospinning device, fix it on the micro-syringe pump, adopt the plate collection method, set the receiving time to 2h, and the process parameters are, voltage 18kV, flow rate 1.0ml / h, The distance is 17cm, and the first layer of PLA nanofibers is obtained, namely figure 1 The lowest level in the middle.

[0021] (3) After the first layer is spun, according to the method of (2), the drug-loaded spinning solution is then continued to be electrospun in the same way, the receiving time is set to ...

Embodiment 2

[0025] (1) Dissolve the weighed CA and CM in a mixed solvent of acetone and dimethylacetamide (volume ratio 3:2), and prepare the CA concentration to be 13%, and the CM concentration to be 10% to 30% (w / w) drug-loaded spinning solution, the weighed PLA was dissolved in the mixed solvent of dichloromethane and dimethylformamide (volume ratio 7: 3), and the spinning solution with 8% PLA concentration was prepared .

[0026] (2) Inject the PLA spinning solution into the syringe of the electrospinning device, fix it on the micro-syringe pump, adopt the plate collection method, set the receiving time to 5h, and the process parameters are, voltage 18kV, flow rate 1.0ml / h, With a distance of 17 cm, the first layer of PLA nanofibers was obtained.

[0027] (3) After the first layer is spun, according to the method of (2), the drug-loaded spinning solution is then continued to be electrospun in the same way, the receiving time is set to 18h, the process parameters are 18kV, and the fl...

Embodiment 3

[0031] (1) Dissolve the weighed CA and CM in a mixed solvent of acetone and dimethylacetamide (volume ratio 3:2), and prepare the CA concentration to be 13%, and the CM concentration to be 10% to 30% (w / w) drug-loaded spinning solution, the weighed PLA was dissolved in the mixed solvent of dichloromethane and dimethylformamide (volume ratio 7: 3), and the spinning solution with 8% PLA concentration was prepared .

[0032] (2) Inject the PLA spinning solution into the syringe of the electrospinning device, fix it on the micro-syringe pump, adopt the plate collection method, set the receiving time to 7h, and the process parameters are, voltage 18kV, flow rate 1.0ml / h, With a distance of 17 cm, the first layer of PLA nanofibers was obtained.

[0033] (3) After the first layer is spun, according to the method of (2), the drug-loaded spinning solution is then continued to be electrospun in the same way, the receiving time is set to 18h, the process parameters are 18kV, and the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com