Application of acorus gramineus polysaccharide in preparing healthcare food having neuroprotective effect

A neuroprotective and health food technology, applied in the function, application, food preparation and other directions of food ingredients, can solve problems such as lack of research on nervous system diseases, and achieve the effects of preventing and treating nervous system diseases, less reagent consumption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

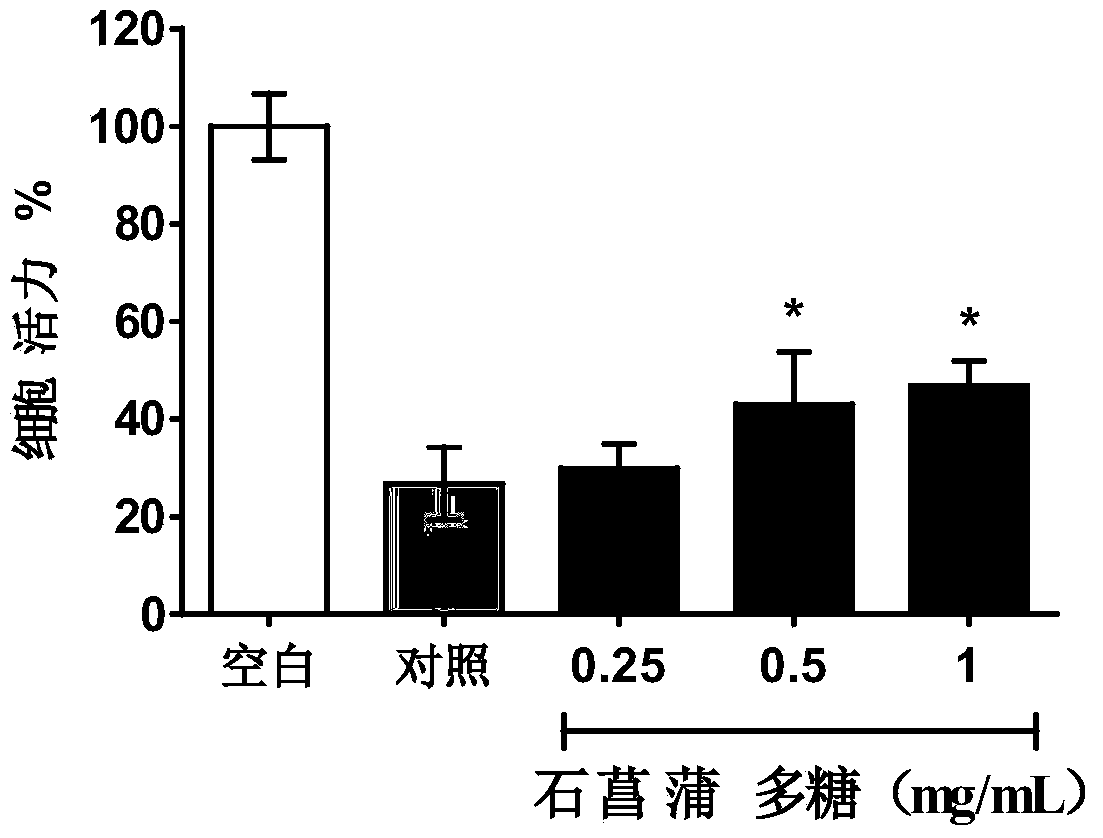

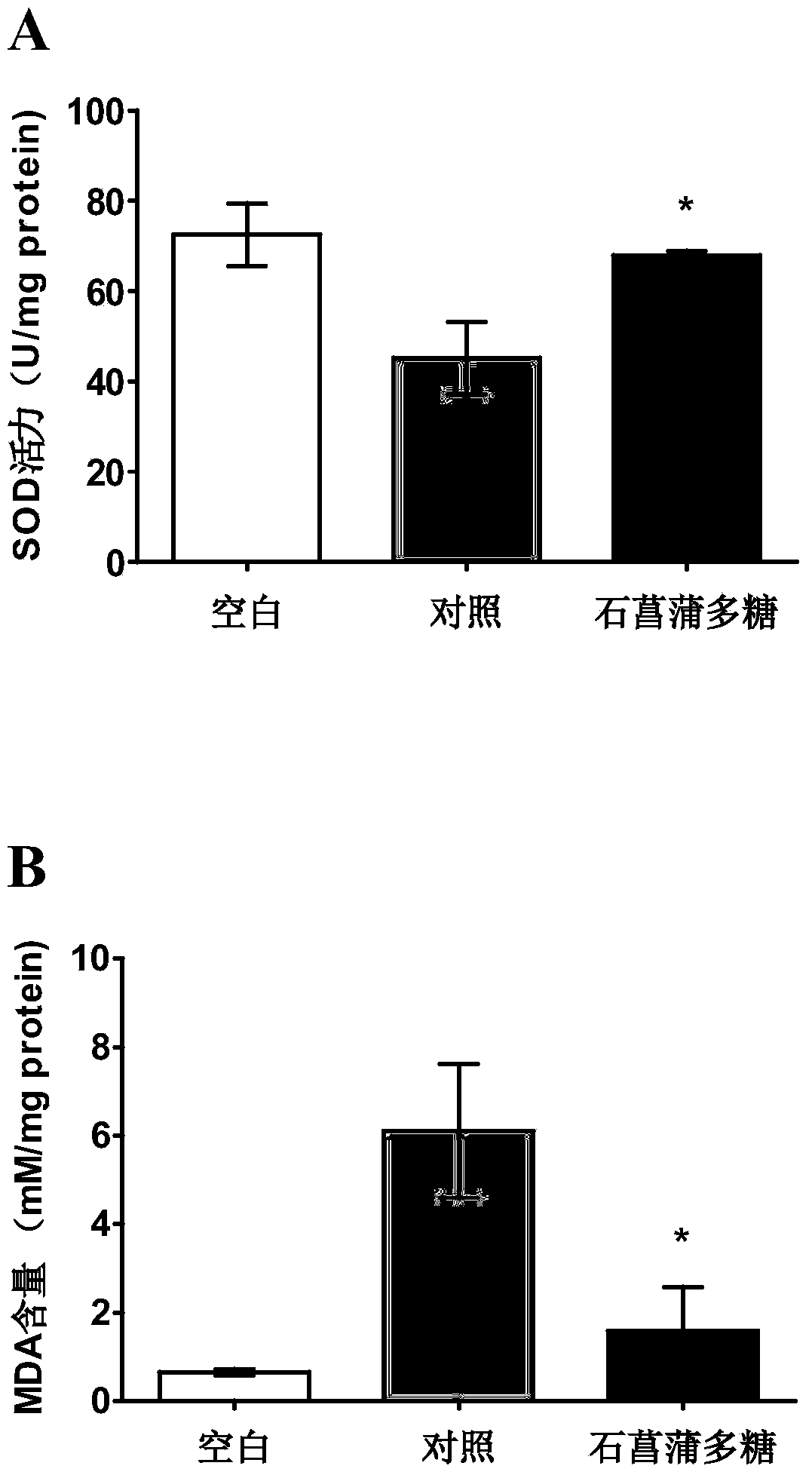

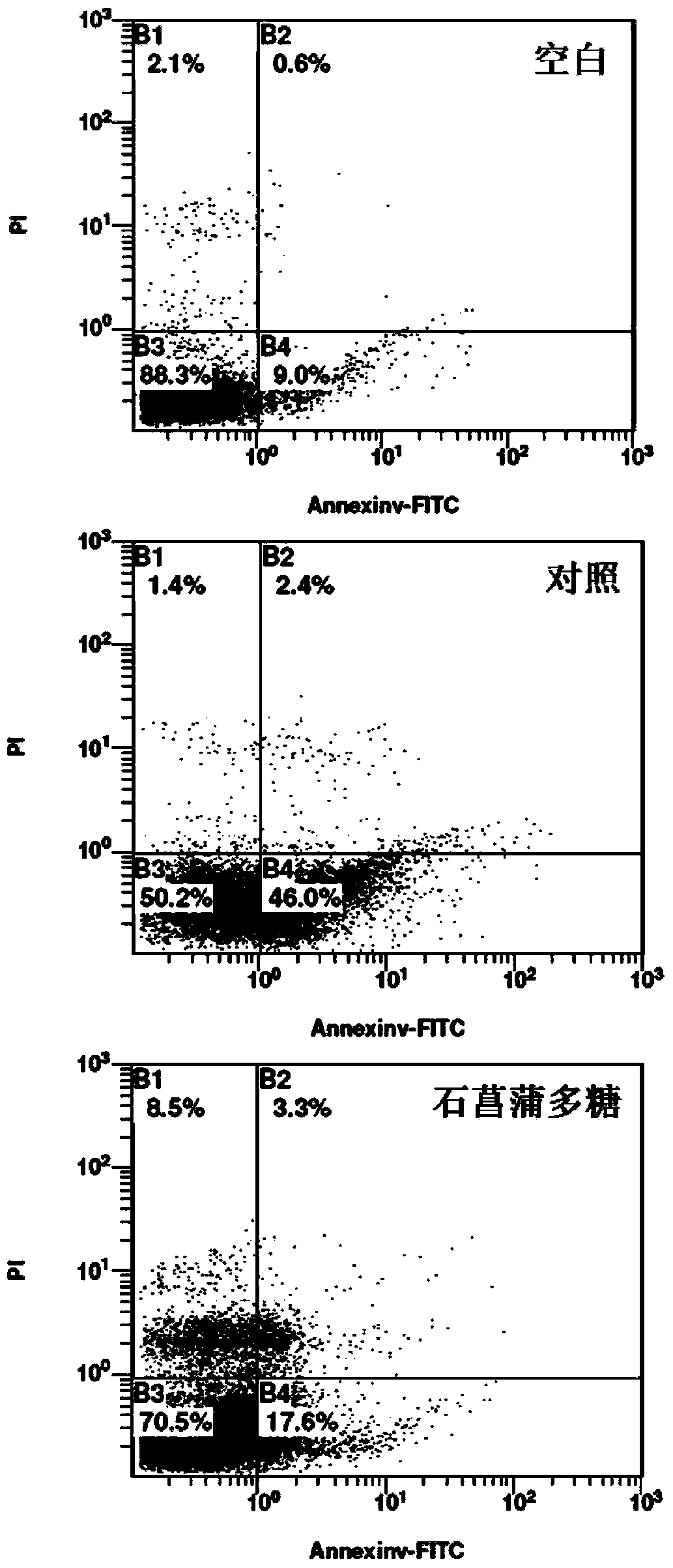

Method used

Image

Examples

Embodiment 1

[0024] This example provides a calamus polysaccharide, which is prepared by the following method: after crushing the rhizomes of calamus, adding ethanol according to the ratio of solid to liquid 1:10 (g / mL), heating and stirring at 70°C for 3 hours, and filtering under reduced pressure Solvents, recovery of medicinal materials. Add water according to the solid-liquid ratio of 1:10 (g / mL), heat and stir at 95°C for 3 hours, and collect the water extract. Concentrate under reduced pressure at 60°C, centrifuge to remove residual medicinal residues and insoluble impurities, and obtain a clear concentrated extract. Add 4 times the volume of ethanol to the above extract, mix well, let stand overnight at 4° C. to precipitate, collect the precipitate by centrifugation and vacuum freeze-dry. Dissolve the precipitate in water and pass through a DEAE-sepharose anion-exchange dextran gel column, then use water and 1.0mol / L NaCl solution to elute sequentially, collect the eluate of 1.0mol...

Embodiment 2

[0026] This example provides an acidic polysaccharide of Acorus calamus, which is prepared by the following method: after crushing the rhizome of Calamus calamus, adding ethanol according to the ratio of solid to liquid of 1:20 (g / mL), heating and stirring at 80°C for 3 hours, and filtering under reduced pressure The solvent is removed and the medicinal materials are recovered. Add water according to the solid-liquid ratio of 1:10 (g / mL), heat and stir at 100°C for 3 hours, and collect the water extract. Concentrate under reduced pressure at 55°C, centrifuge to remove residual medicinal residues and insoluble impurities, and obtain a clear concentrated extract. Add 4 times the volume of ethanol to the above extract, mix well, let stand overnight at 4° C. to precipitate, collect the precipitate by centrifugation and vacuum freeze-dry. Dissolve the precipitate in water and pass through a DEAE-sephadex A-25 anion-exchange cellulose column, elute with water and 2.0mol / L KCl solut...

Embodiment 3

[0028] This example provides an acidic polysaccharide of Acorus calamus, which is prepared by the following method: after crushing the rhizome of Calamus calamus, adding ethanol according to the ratio of solid to liquid 1:5 (g / mL), heating and stirring at 85°C for reflux for 3 hours, and filtering under reduced pressure The solvent is removed and the medicinal materials are recovered. Add water according to the solid-liquid ratio of 1:15 (g / mL), heat and stir at 90°C for 4 hours, and collect the water extract. Concentrate under reduced pressure at 50°C, centrifuge to remove residual medicinal residues and insoluble impurities, and obtain a clear concentrated extract. 5 times the volume of ethanol was added to the above extract, mixed evenly and left to settle at 4°C overnight, and the precipitate was collected by centrifugation and vacuum freeze-dried. Dissolve the precipitate in water and pass it through D900 type anion exchange resin, then use water and 1.0mol / L ammonium ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com