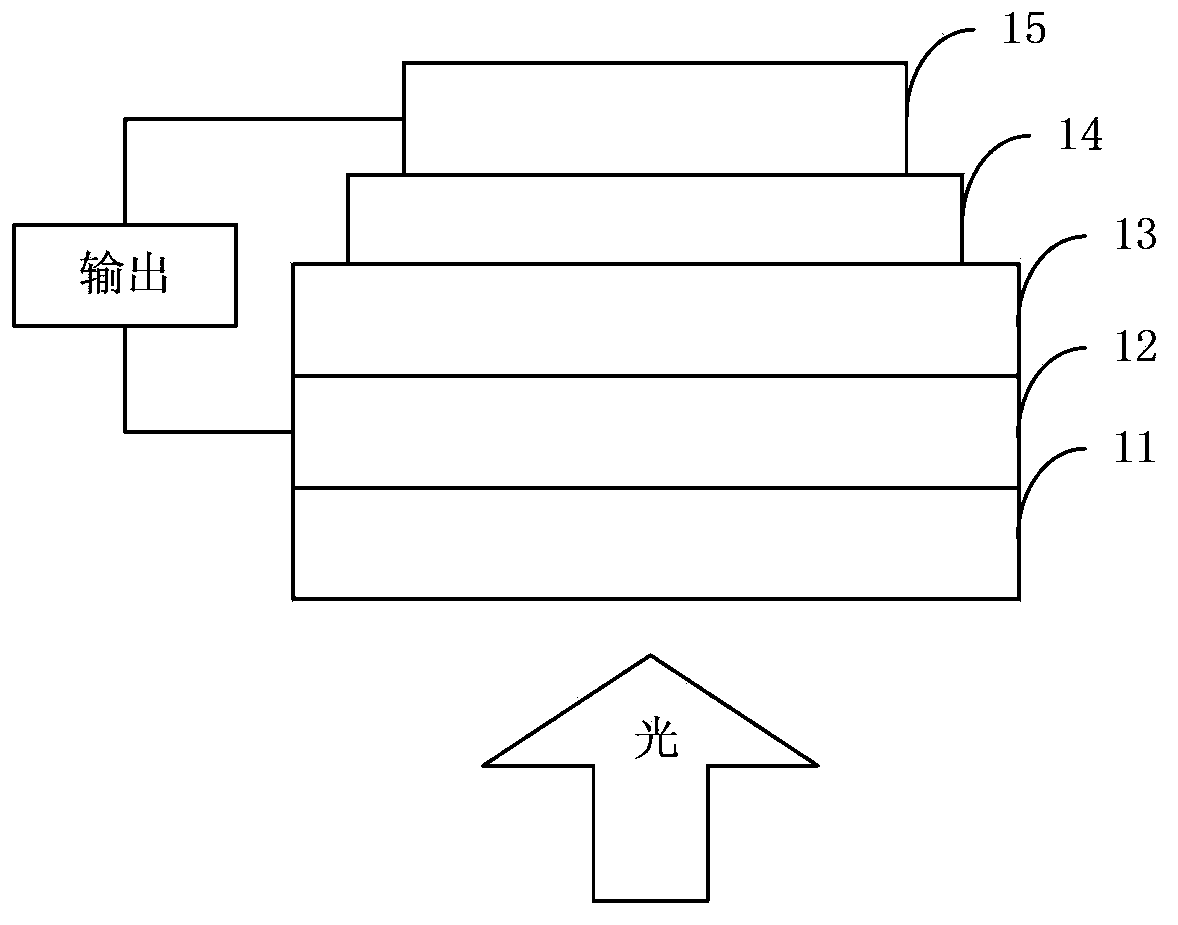

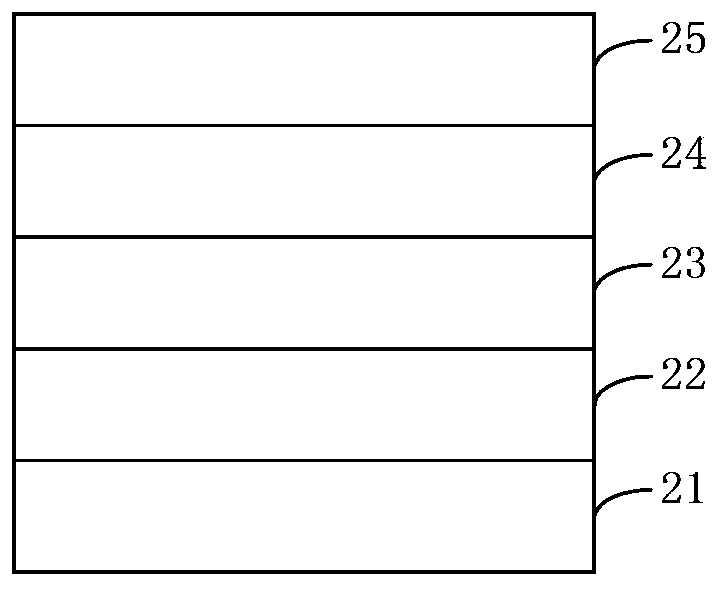

Copolymer containing siliconfluorene-benzobis(benzothiadiazole), preparation method thereof and applications thereof

A technology of benzothiadiazole and copolymer, which is applied in the field of organic semiconductor materials, can solve problems such as limiting the scope of application, and achieve the effects of expanding the absorption range, improving stability, improving solubility and molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the preparation method of the above-mentioned silicon-containing fluorene-benzobis(benzothiadiazole) copolymer, comprising the steps of:

[0033] S1, the preparation structural formula is Compound A (i.e. 5-nitro-2,1,3-benzothiadiazole):

[0034] 1. The structural formula is Compound I (4-nitrobenzene-1,2-diamine) was added in thionyl chloride, stirred and added to thionyl chloride (structural formula is ) was added dropwise pyridine (the structural formula is Molecular formula is C 5 h 5 N,), reflux reaction at 85 ° C, stop the reaction, the obtained structural formula is Compound F (that is, 5-nitro-2,1,3 benzothiadiazole); the reaction formula is as follows:

[0035]

[0036] Compound F is preferably purified by:

[0037] Heating the reaction solution to 80°C and rotary evaporating excess SOCl 2 Afterwards, the reaction product was cooled to room temperature, poured into a large amount of water, stirred, filtered, w...

Embodiment 1

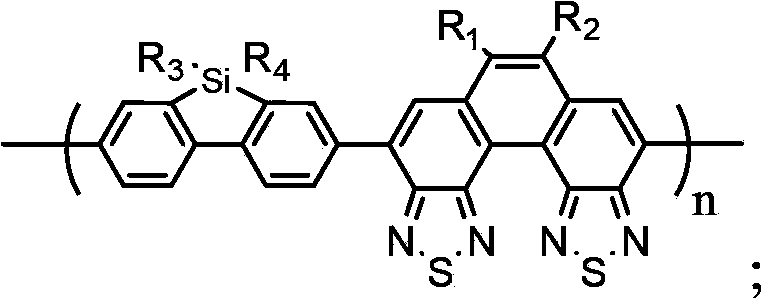

[0065] The copolymer containing silicon fluorene-benzobis(benzothiadiazole) in this embodiment, that is, poly{9,9-dioctylsilylfluorene-6,7-bis(3,7-dimethyl)octane Base-benzo[2,1-e:3,4-e]bis(benzothiadiazole)}, its structural formula is as follows:

[0066] n=48

[0067] The preparation process is as follows:

[0068] 1. Preparation of 4,4'-dibromo-6,6'-diiodo-bi-2,1,3-benzothiadiazole

[0069] 1. Preparation of compound 5-nitro-2,1,3 benzothiadiazole

[0070]

[0071] Add 4-nitrobenzene-1,2-diamine (22.95g, 0.15mol) and 100ml of thionyl chloride into a three-necked flask, stir and slowly add 2ml of pyridine dropwise, heat and reflux at 85°C for 24h, stop Reaction, heated to 80 °C and rotary evaporated excess SOCl 2 Finally, the reaction product was cooled to room temperature, poured into a large amount of water, stirred, filtered, washed with water and dried in vacuum to obtain 21.7 g of the purified product 5-nitro-2,1,3-benzothiadiazole with a yield of 80%;

[0072...

Embodiment 2

[0091] The copolymer containing silicon fluorene-benzobis(benzothiadiazole) in this embodiment, that is, poly{9,9-didecylsilafluorene-6,7-bis(3,7-dimethyl)octane Base-benzo[2,1-e:3,4-e]bis(benzothiadiazole)}, its structural formula is as follows:

[0092] n=54

[0093] The preparation process is as follows:

[0094] 1. Preparation of 4,4'-dibromo-6,6'-diiodo-bi-2,1,3 benzothiadiazole This step 1 is the same as step 1 in Example 1.

[0095] 2. Poly{9,9-didecylsilylfluorene-6,7-bis(3,7-dimethyl)octyl-benzo[2,1-e:3,4-e]bis(benzo Thiadiazole)} preparation

[0096] The second step is the same as the second step in the implementation 1.

[0097] 3. Preparation of 9,9-didecyl-2,7-bis(tributyltin)silafluorene

[0098]

[0099] Under the protection of argon, add 9,9-didecyl-2,7-dibromosilafluorene (6.21g, 0.01mol) into the three-necked flask, add 100ml of tetrahydrofuran solvent, and use Slowly inject n-butyllithium (8.4mL, 2.5M, 0.02mol) into the syringe, continue to stir t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Maximum brightness efficiency | aaaaa | aaaaa |

| Maximum brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com