Cu-Im-Ga-S-Se-sensitized semiconductor anode solar cell and preparation method thereof

A technology of copper indium gallium sulfide and solar cells, which is applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems that batteries cannot be used and are difficult to overcome, and achieve the effect of effective transmission and tight chemical combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

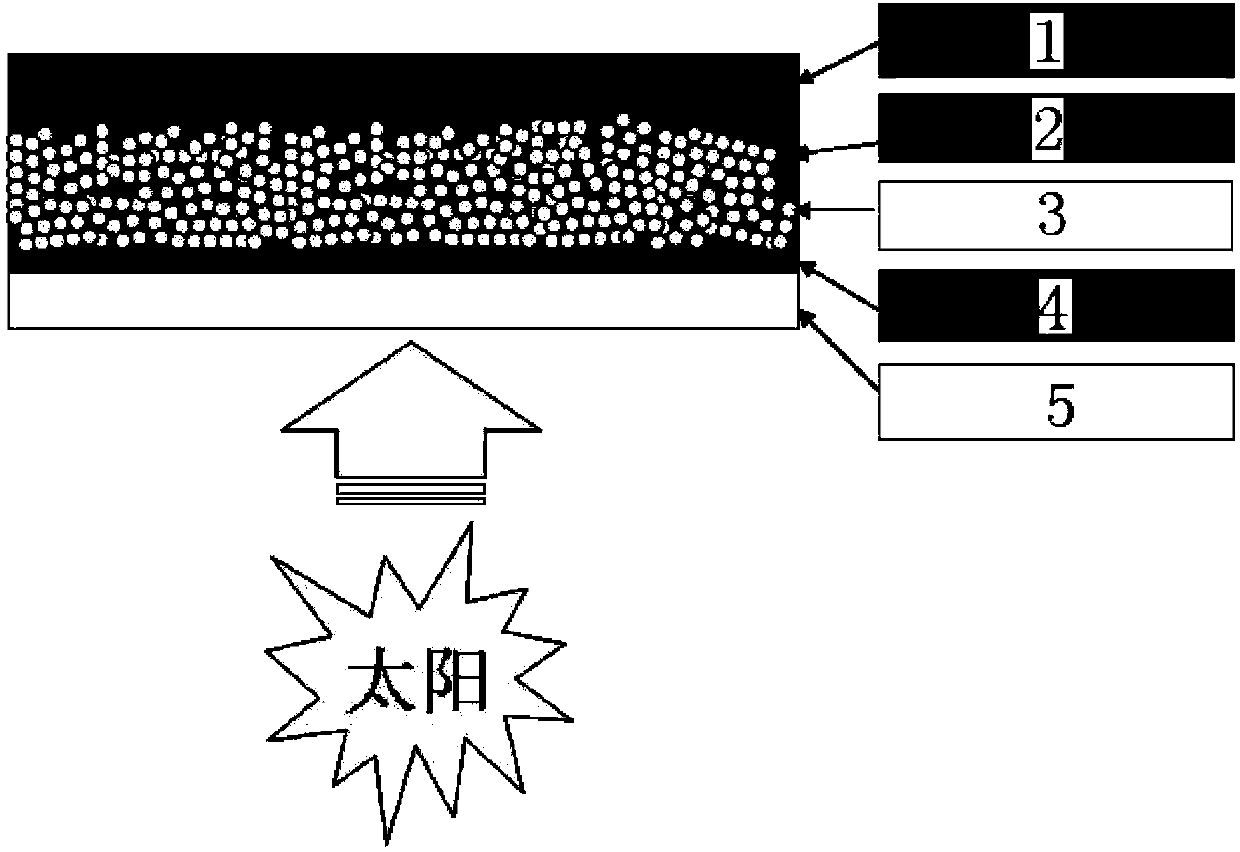

[0065] Such as figure 1 The all-solid copper indium gallium sulfur selenide sensitized semiconductor anode solar cell prepared in this example is shown, wherein: 1 is the back electrode, 2 is the copper indium gallium sulfur selenide sensitizing layer, 3 is the N-type semiconductor porous film, and 4 is the N-type transparent conductive film, 5 is a glass substrate, and the specific preparation method is as follows:

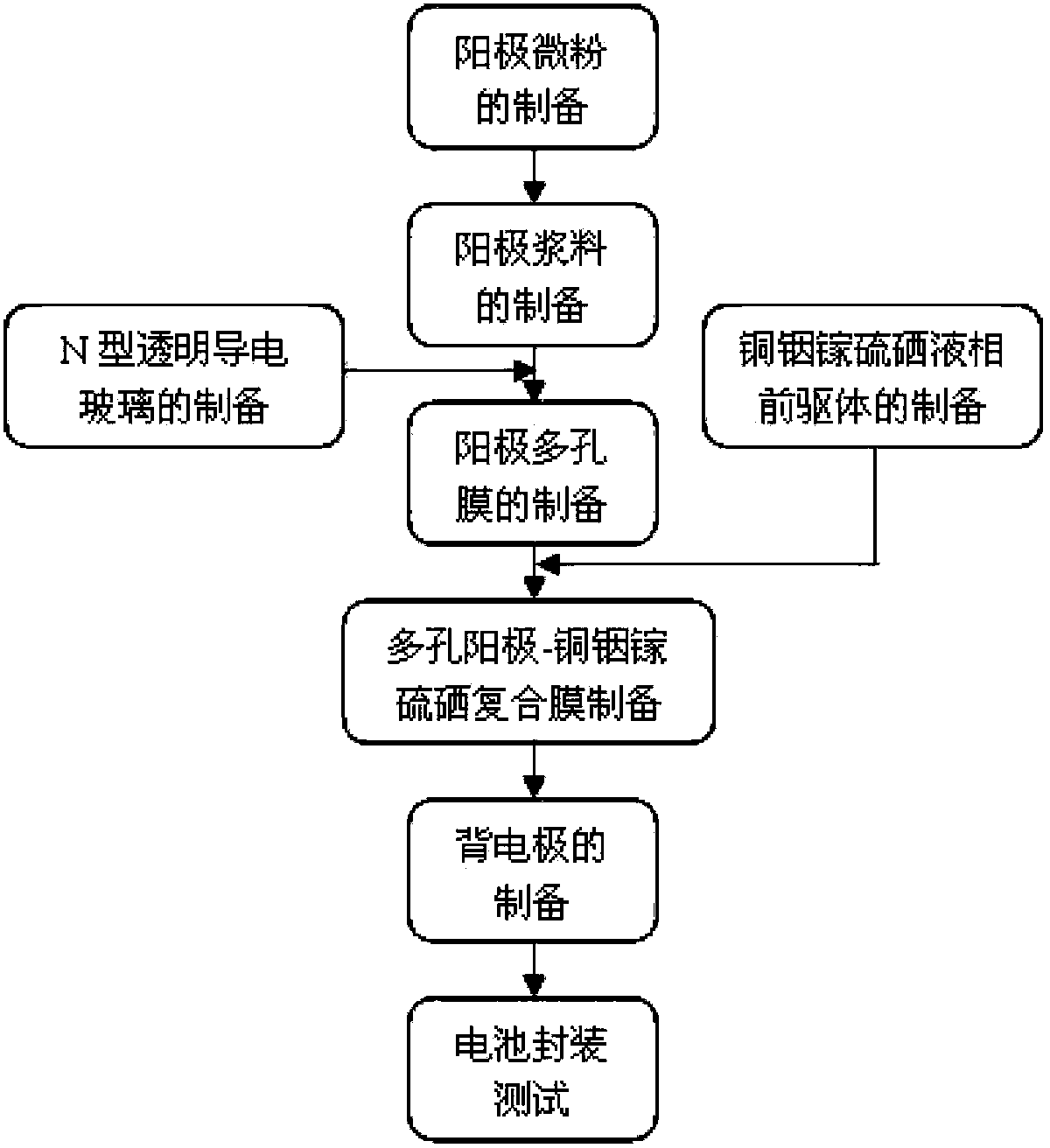

[0066] 1. Preparation of semiconductor anode porous membrane

[0067]1) Material selection and preparation of N-type transparent conductive film

[0068] In this example, AZO is selected as the N-type transparent conductive film material, and then ordinary soda-lime-silica glass is used as the substrate, and a transparent conductive AZO with a sheet resistance of less than 10Ω / □ and a transmittance higher than 85% is prepared by magnetron sputtering. The film is used for all-solid copper indium gallium sulfide selenide sensitized semiconductor anode solar cells...

Embodiment 2

[0081] 1. Preparation of semiconductor anode porous membrane

[0082] 1) Material selection and preparation of N-type transparent conductive film

[0083] In this example, FTO is selected as the N-type transparent conductive film material, and then ordinary soda-lime-silica glass is used as the substrate, and a transparent film with a sheet resistance of less than 10Ω / □ and a transmittance higher than 85% is prepared by a sol-gel film-making process. Conductive FTO film used in all-solid copper indium gallium sulfide selenide sensitized semiconductor anode solar cells;

[0084] 2) Selection of N-type wide bandgap semiconductor materials and preparation of micropowders

[0085] In this embodiment, ZnS is selected as the anode material of copper indium gallium sulfide selenide sensitized semiconductor anode solar cell, and the preparation method of its micropowder adopts sol-gel method. The specific operation steps and parameters are: mix 100ml of 0.2M zinc sulfate aqueous solu...

Embodiment 3

[0096] 1. Preparation of semiconductor anode porous membrane

[0097] 1) Material selection and preparation of N-type transparent conductive film

[0098] Select Zn in this embodiment 2 SnO 4 As an N-type transparent conductive film material, and then using ultra-white solar glass as a substrate, the transparent conductive Zn with a sheet resistance of less than 10Ω / □ and a transmittance higher than 85% was prepared by spray pyrolysis. 2 SnO 4 Thin films are used in all-solid copper indium gallium sulfide selenide sensitized semiconductor anode solar cells;

[0099] 2) Selection of N-type wide bandgap semiconductor materials and preparation of micropowders

[0100] In this embodiment, BiOCl is selected as the anode material of the copper indium gallium sulfide selenide sensitized semiconductor anode solar cell, and the preparation method of its micropowder adopts the micellar method, and the specific operation steps and parameters are as follows: 3.0g Bi(NO 3 ) 3 ·5H 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com